Scanning type electrodeposition processing method and device adopting parallel arrangement of multiple line anodes

A processing device and electrodeposition technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low production efficiency and slow deposition speed, and achieve the effect of small edge effect, elimination of partial thickness phenomenon, and avoiding the aggravation of edge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

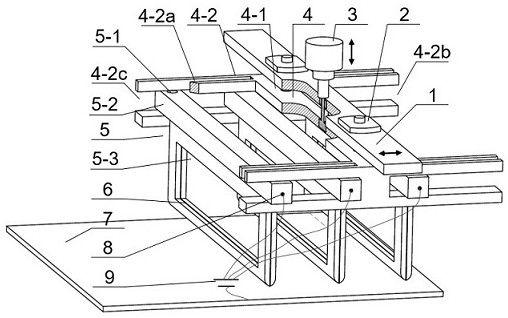

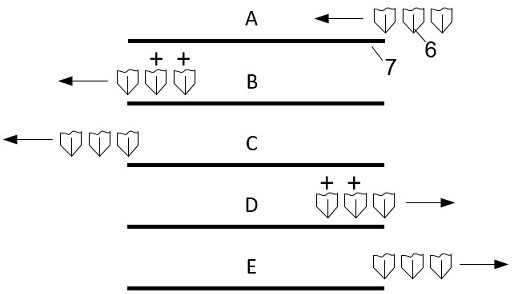

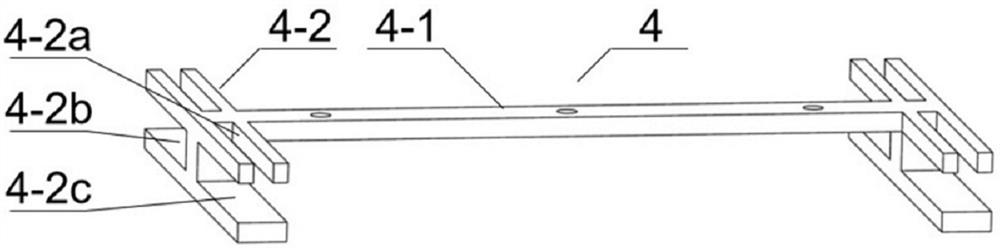

[0023] refer to figure 1 , figure 2 and image 3 , The device of the present invention includes a fixed plate 2, a stirring paddle 5, a linear anode 6, a cathode base 7 and an electrodeposition power supply 9, and it also includes a paddle mounting frame 4 and a touch device 8. The stirring paddle installation frame 4 is provided with crossbeam 4-1 and side beam 4-2, and sidebeam 4-2 is two, is respectively positioned at the two ends of crossbeam 4-1 and is all vertical with crossbeam 4-1, and sidebeam 4-2 A front guide groove 4-2b and a rear guide groove 4-2c are provided. The paddle 5 is sheet-shaped, with a through hole 5-3 in the middle, and a mounting shaft 5-2 on the left and right sides of the upper part, and the mounting shaft 5-2 is slidably connected to the front guide groove 4-2b or 4-2c , and then install the touch device 8 at the end of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com