Iron-based catalyst for preparing ethanol by CO2 hydrogenation, and preparation method and application thereof

An iron-based catalyst, a technology for producing ethanol, applied in catalyst activation/preparation, hydroxyl compound preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of large output and low ethanol selectivity, and achieve The effect of efficient conversion of CO2, alleviation of environmental pressure, and regulation of product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

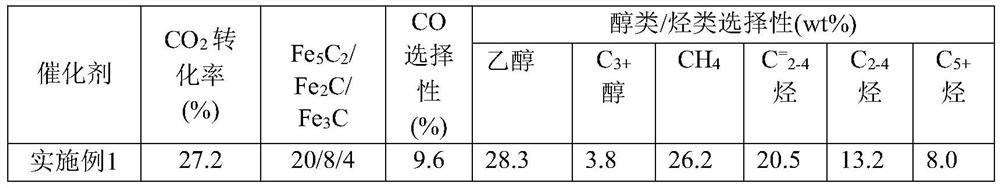

Embodiment 1

[0038] a CO 2 The preparation method of the iron-based catalyst of hydrogenation ethanol, comprises the steps:

[0039] 1) dissolving the auxiliary salt lithium citrate into solvent water to obtain an aqueous solution of lithium citrate;

[0040] 2) Lithium citrate aqueous solution impregnated into Fe 3 o 4 On the catalyst powder, after stirring evenly, dry at 120°C for 12 hours to obtain the catalyst;

[0041] 3) The catalyst is compressed at 10MPa, and then granulated to 20-40 mesh to obtain the catalyst;

[0042] 4) Load 0.5g of catalyst, and first reduce it with synthesis gas. The specific reduction condition is 300°C, and the gas velocity is

[0043] 4500h -1 (V / V), the reduction time is 10 h, and after the reduction is completed, the catalyst is lowered to room temperature with nitrogen to obtain the product. Fe in the product 5 C 2 / Fe 2 C / Fe 3 The ratio of C is finally adjusted to 20 / 8 / 4.

[0044] Efficient catalytic conversion of CO 2 Experimental conditio...

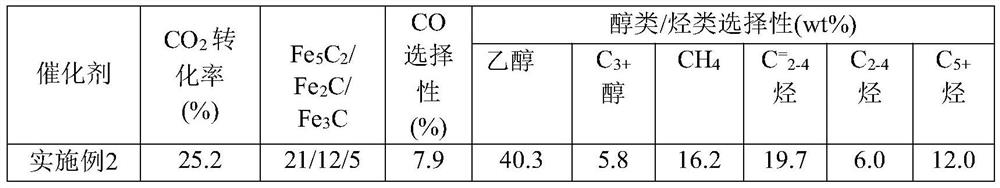

Embodiment 2

[0047] a CO 2 The preparation method of the iron-based catalyst of hydrogenation ethanol, comprises the steps:

[0048] 1) dissolving the auxiliary salt trisodium citrate into solvent water to obtain an aqueous solution of trisodium citrate;

[0049] 2) Immerse trisodium citrate aqueous solution into Fe 3 o 4 On the catalyst powder, after stirring evenly, dry at 120°C for 12 hours to obtain the catalyst;

[0050] 3) The catalyst is compressed at 10MPa, and then granulated to 20-40 mesh to obtain the catalyst;

[0051] 4) Load 0.5g of catalyst, first reduce it with synthesis gas, the specific reduction condition is 300°C, and the gas velocity is 4500h -1 (V / V), the reduction time is 10 h, and after the reduction is completed, the catalyst is lowered to room temperature with nitrogen to obtain the product.

[0052] Efficient catalytic conversion of CO 2 Experimental conditions: fixed bed reactor, temperature 300°C, pressure 3MPa, mixed gas H 2 / CO 2 =3, gas velocity is 2...

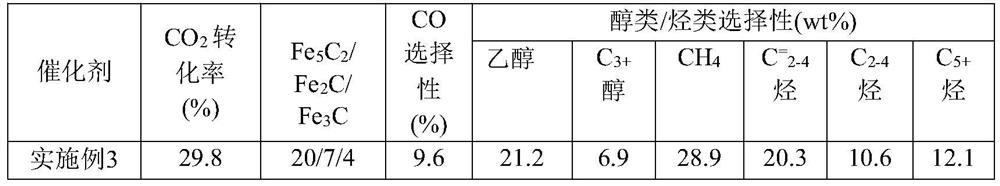

Embodiment 3

[0056] a CO 2 The preparation method of the iron-based catalyst of hydrogenation ethanol, comprises the steps:

[0057] 1) dissolving the auxiliary salt tripotassium citrate into solvent water to obtain tripotassium citrate aqueous solution;

[0058] 2) Immerse tripotassium citrate aqueous solution into Fe 3 o 4 On the catalyst powder, after stirring evenly, dry at 120°C for 12 hours to obtain the catalyst;

[0059] 3) The catalyst is compressed at 10MPa, and then granulated to 20-40 mesh to obtain the catalyst;

[0060] 4) Load 0.5g of catalyst, first reduce it with synthesis gas, the specific reduction condition is 300°C, and the gas velocity is 4500h -1 (V / V), the reduction time is 10 h, and after the reduction is completed, the catalyst is lowered to room temperature with nitrogen to obtain the product.

[0061] Efficient catalytic conversion of CO 2 Experimental conditions: fixed bed reactor, temperature 300°C, pressure 3MPa, mixed gas H 2 / CO 2 =3, gas velocity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com