Pearlite spheroidizing method based on high-speed wire production line

A technology for high-speed wire rods and production lines, which can be used in temperature control, metal rolling, etc., and can solve the problems of contradicting inventive concepts and not providing pearlite spheroidization methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

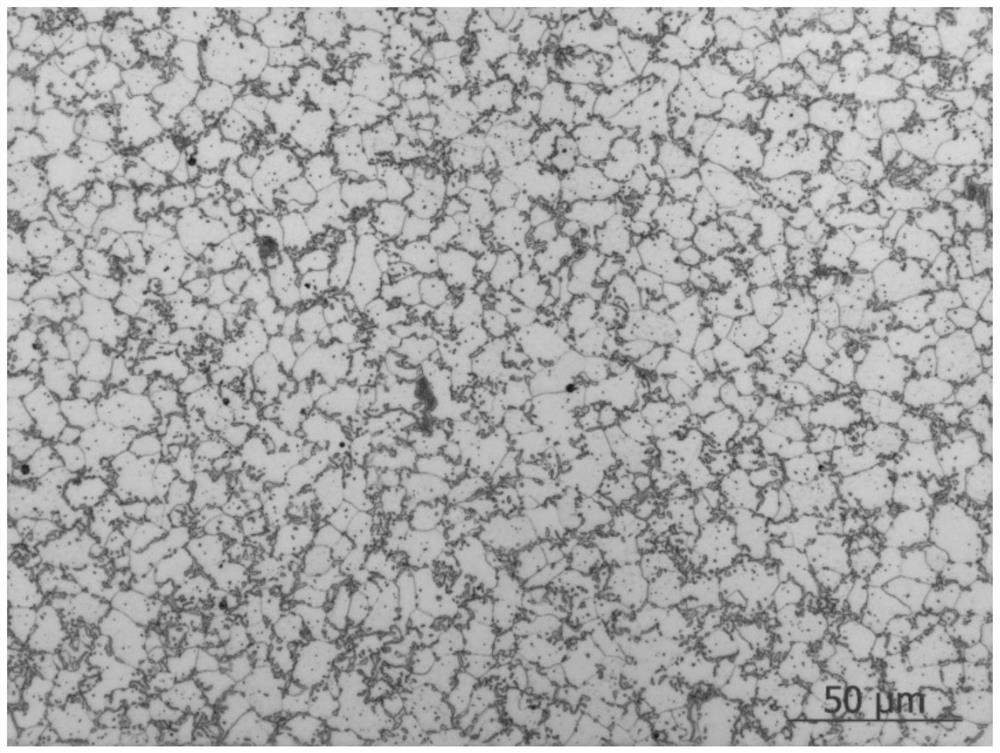

Embodiment 1

[0036] 1. Billet heating

[0037] Continuous casting slab composition C: 0.35%, Si: 0.12%, Mn: 0.76%, P: 0.011%, S: 0.008%, Cr: 0.08%, Ni: 0.05%, Cu: 0.03%, Al: 0.031%.

[0038] Heat the continuous casting slab with a cross-section of 160mm×160mm in a regenerative walking heating furnace, heat the first stage at 700-800°C for 35 minutes, heat the second stage at 900-1000°C for 35 minutes, and soak at 1000-1000°C Heating at 1050°C for 50 minutes.

[0039] 2. Low temperature controlled rolling

[0040] After the billets are deformed at 850-950°C for rough-intermediate rolling and pre-finishing rolling respectively, by adjusting the water flow in the water tank, the temperature at the entrance of the billets to the finish rolling unit and the reducing and sizing unit is controlled at 700-760°C. Water, so that the final rolling temperature ≤ 780 ℃.

[0041] 3. Low temperature spinning

[0042] After final rolling, the spinning temperature of the wire rod is controlled at 720-7...

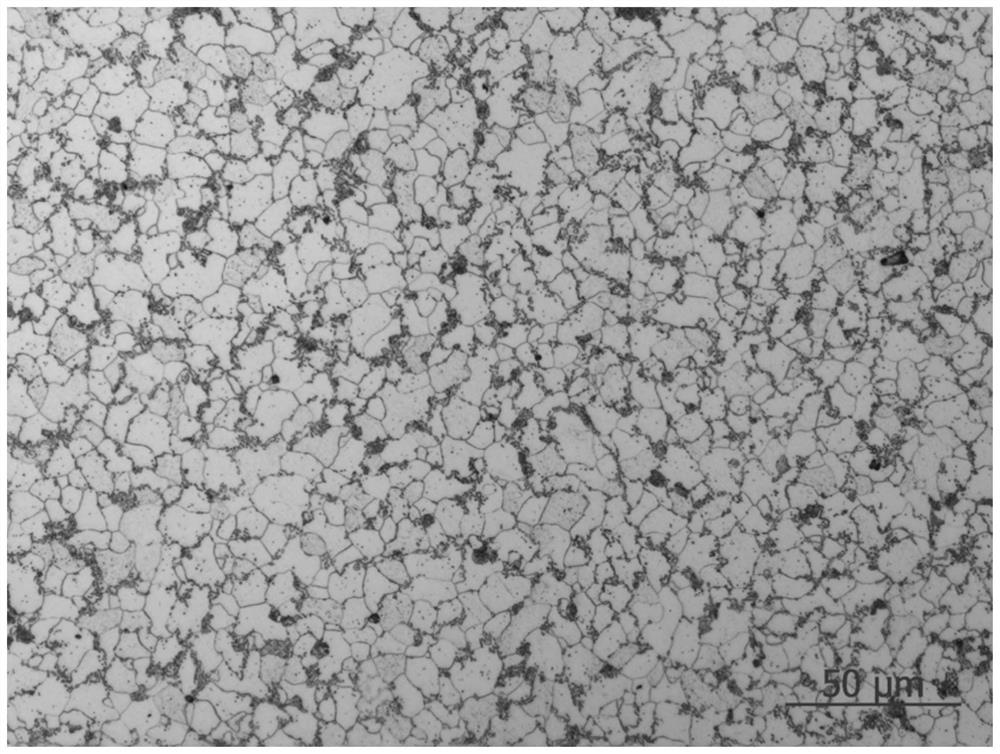

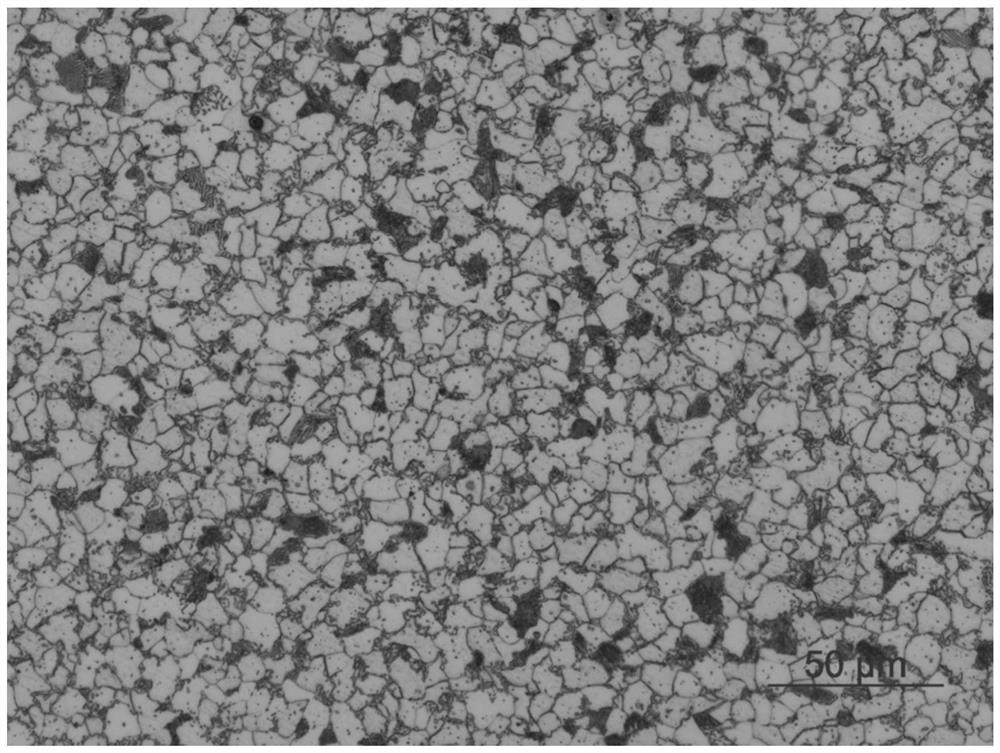

Embodiment 2

[0047] 1. Billet heating

[0048] Continuous casting slab composition C: 0.21%, Si: 0.05%, Mn: 0.86%, P: 0.013%, S: 0.006%, Cr: 0.13%, Ni: 0.02%, Cu: 0.04%, Al: 0.045%.

[0049] Heat the continuous casting slab with a cross-section of 160mm×160mm in a regenerative walking heating furnace, heat the first stage at 700-800°C for 35 minutes, heat the second stage at 900-1000°C for 35 minutes, and soak at 1000-1000°C Heating at 1050°C for 50 minutes.

[0050] 2. Low temperature controlled rolling

[0051] After the billet is deformed at 850-950°C for rough, intermediate rolling and pre-finishing rolling, by adjusting the water flow in the water tank, the temperature at the entrance of the billet to the finish rolling unit and the reducing and sizing unit is controlled at 700-760°C. , so that the final rolling temperature ≤ 780 ℃.

[0052] 3. Low temperature spinning

[0053] After final rolling, the spinning temperature of the wire rod is controlled at 720-780°C by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com