Nickel-based high-corrosion-resistance composite steel pipe welding method

A composite steel pipe and welding method technology, applied in the field of iron and steel material welding, can solve the problems of welding materials and welding process complexity, etc., and achieve the effect of improving welding efficiency, improving work efficiency, and ensuring strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

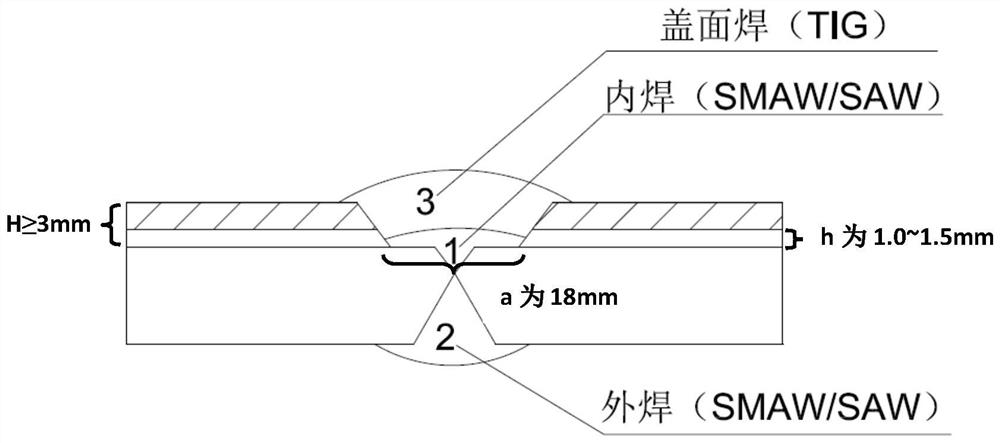

[0023] Adopt welding method of the present invention, first carry out the location pre-welding of L450MS steel, carry out double-sided welding (inner welding and outer welding) of L450MS steel successively with manual welding again, carry out non-melting extremely inert gas to transition layer metal and coating metal at last Tungsten arc welding (TIG).

[0024] The welding process parameters of manual welding are as follows:

[0025] Table 1 SMAW welding process parameters

[0026]

[0027] Table 2 SAW welding process parameters

[0028]

[0029] The performance test results are as follows:

[0030] Table 3 Tensile test results of SMAW welded joints

[0031]

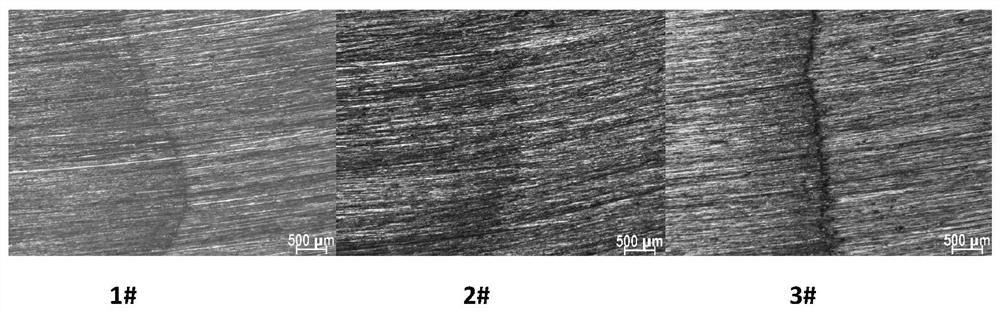

[0032] The fracture position of the welding test and the tensile test of the two methods are all on the base metal. The standard requires: the strength of the welded joint of Rm 535-760MPa is not lower than that of the base metal, and the strength of the welded joint is qualified.

[0033] Table 4 Impact tes...

Embodiment 2

[0047] Adopt the welding method of the present invention, first carry out the pre-positioning welding of L450MS steel, then carry out the double-sided welding of L450MS steel successively with submerged arc automatic welding, and finally carry out non-melting inert gas tungsten electrode shielded welding to the transition layer metal and cladding metal ( TIG).

[0048] welded joint tension

[0049] Table 6 Tensile test results of SAW welded joints

[0050] Sample No Sample size / mm Rm / MPa Fracture site NG 19×25×360 607 base material NG 19×25×360 600 base material BJ 19×25×360 610 base material

[0051] The impact test results of each part of the steel plate welded joint are shown in Table 7.

[0052] Table 7 Impact test results of SAW welded joints

[0053]

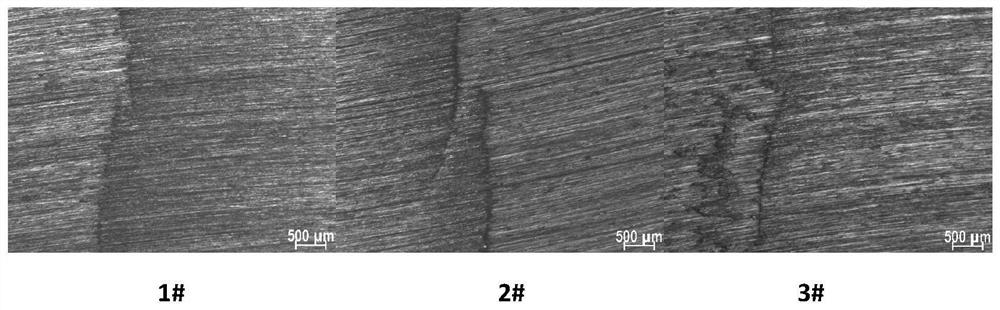

[0054] The technical requirements are that the single value of weld and HAZ is ≥38J, and the average value is ≥45J. It can be seen from the results that the impact toug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com