Sewage treatment equipment based on sewage centralized treatment technology

A sewage treatment equipment and centralized treatment technology, applied in water/sewage treatment equipment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as operational defects, difficult sewage collection, low efficiency, etc., to achieve Less work, less corrosive effects, better mixing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

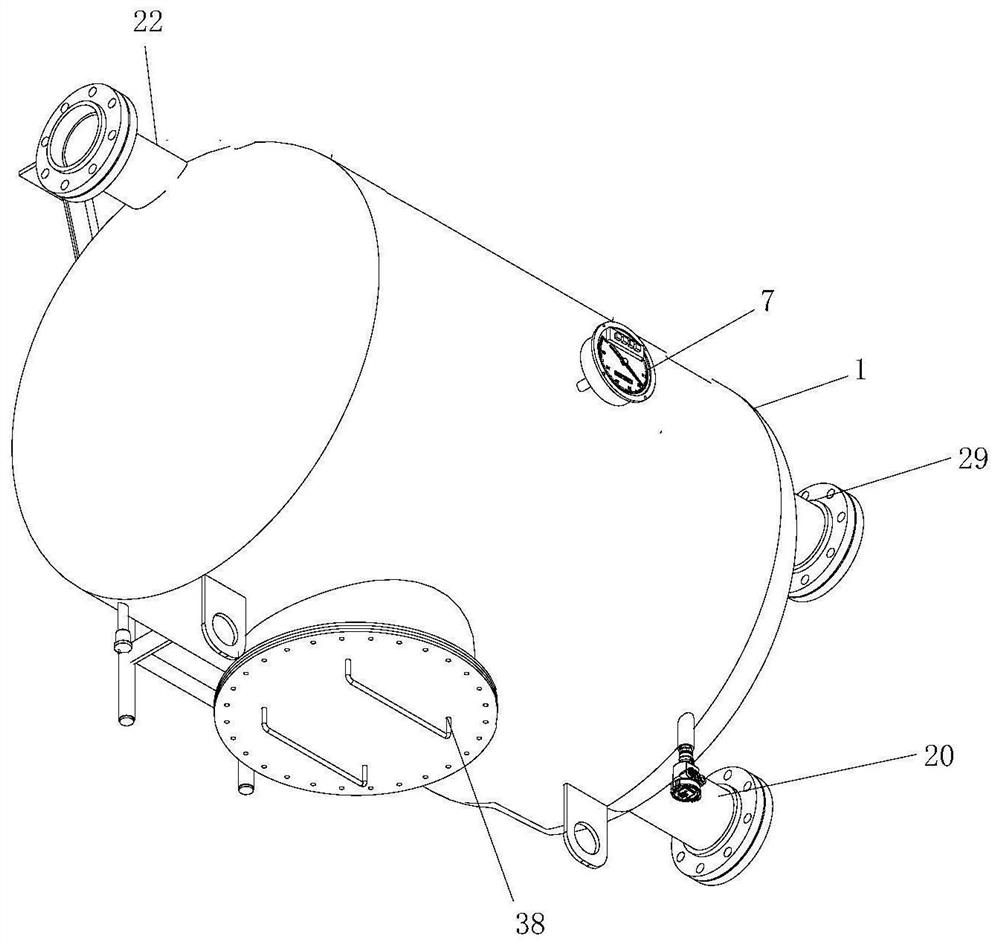

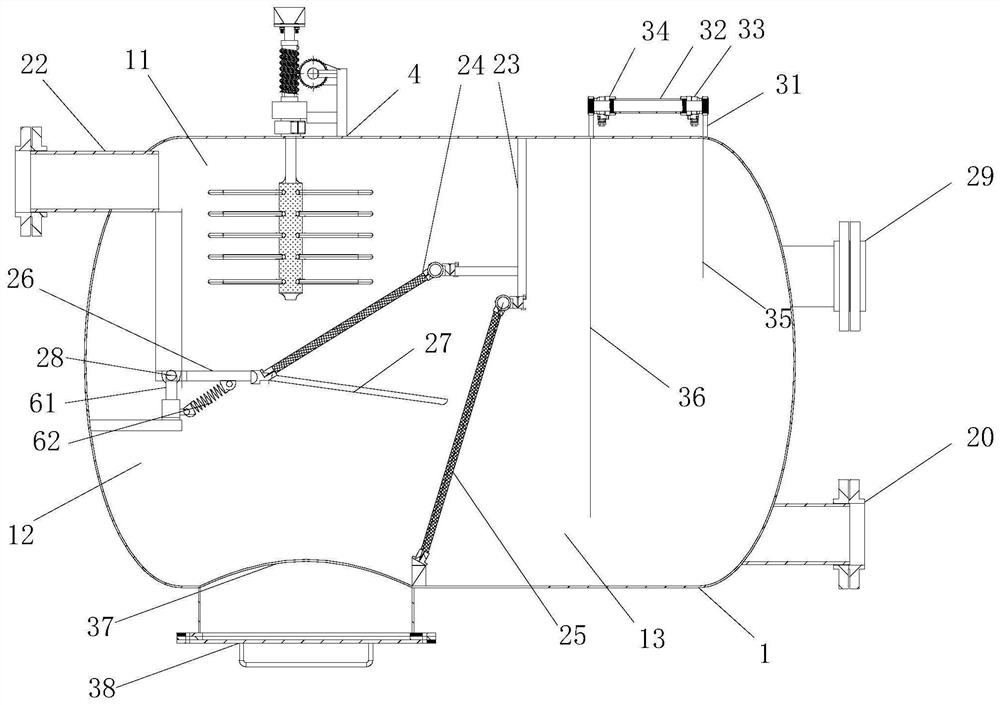

[0029] see figure 1 with figure 2 , a kind of sewage treatment equipment based on the centralized sewage treatment technology, including a treatment box 1, the inner cavity of the treatment box 1 is respectively provided with a crushing chamber 11, a solid separation chamber 12 and a liquid separation chamber 13, the treatment box 1 The water pipe 22 is connected to the top of one side, and the water inlet pipe 22 leads into the crushing chamber 11. The crushing chamber 11 is used for crushing the input dirt, and the solid separation chamber 12 and the liquid separation chamber 13 separate the solid and liquid. The dirt and sewage are separated and output.

[0030] The inner cavity of the processing chamber 1 is provided with a spacer 23, and the spacer 23 is respectively equipped with a primary filter screen 24 and a secondary filter screen 25, and the primary filter screen 24 is erected in the crushing chamber in an inclined direction. 11. Between the solid separation cha...

Embodiment 2

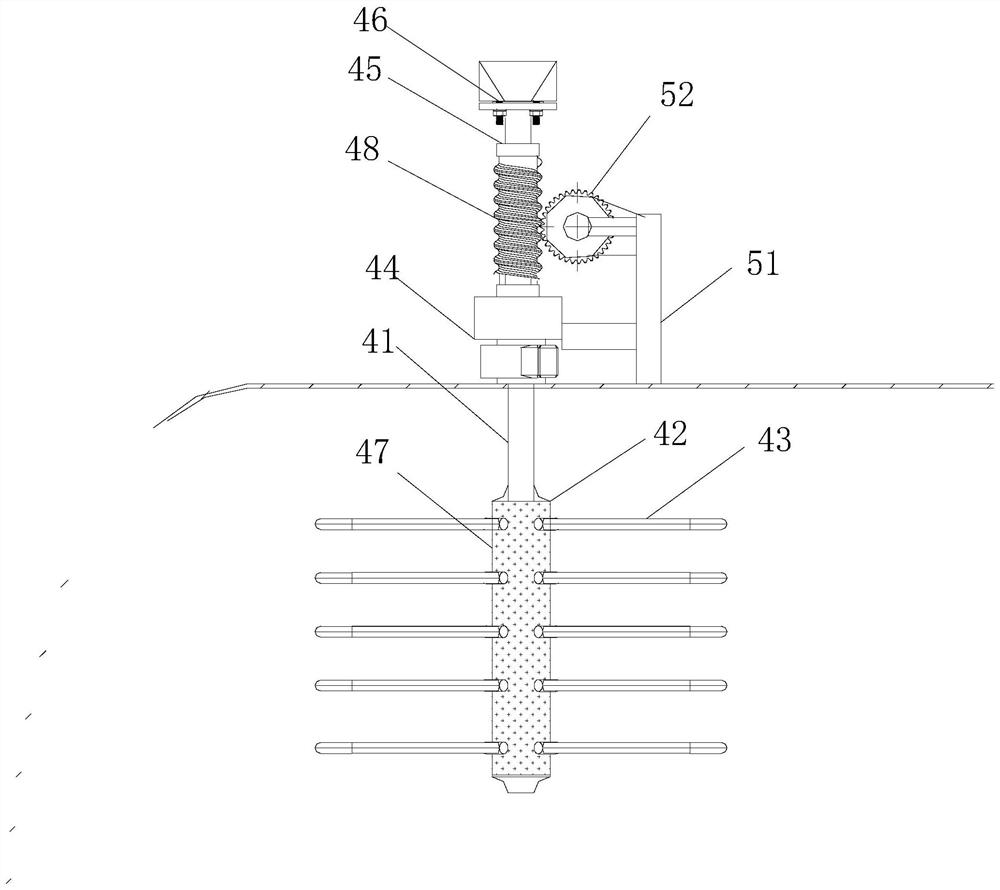

[0035] see image 3 with Figure 4 In this embodiment, as a further optimization of Embodiment 1, on the basis of this, a crushing shaft 41 is installed on the crushing frame 4, and the crushing shaft 41 extends into the inner cavity of the crushing cavity 11 and is equipped with a stirring sleeve 42, so The outer wall of the stirring sleeve 42 is equidistantly equipped with several crushing blades 43, the rotating shaft of the crushing shaft 41 adopts an inner hollow structure design, and the top of the crushing shaft 41 is externally connected with a water delivery pipeline 45, and the stirring sleeve Several water outlet holes 47 are arranged on the outer wall of 42 , and the water delivery pipe 45 is connected with the crushing shaft 41 through a seal sleeve 44 , and a liquid inlet bucket 46 is installed on the top of the water delivery pipe 45 .

[0036] The application sets the crushing frame 4 for crushing treatment, and the design of the crushing shaft 41 adopts an in...

Embodiment 3

[0040] see figure 1 , this embodiment is a further optimization of Embodiment 1, on the basis of which, a pressure detector 7 is arranged on the outer wall of the processing chamber 1, and the pressure measuring end of the pressure detector 7 communicates with the inner cavity of the processing chamber 1 . In view of the electrolysis and disinfection reaction mechanism designed in this application, a pressure detector 7 is also arranged on the processing chamber 1 to improve the safety of equipment operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com