Organic compound and organic light-emitting device

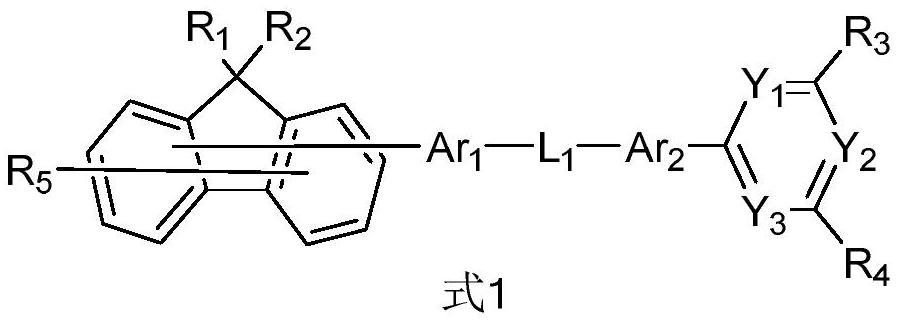

An organic compound, selected technology, applied in the direction of organic chemistry, electrical solid-state devices, electrical components, etc., can solve the problems of low performance and not very good organic electroluminescent devices, achieve good life, improve exciton utilization, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

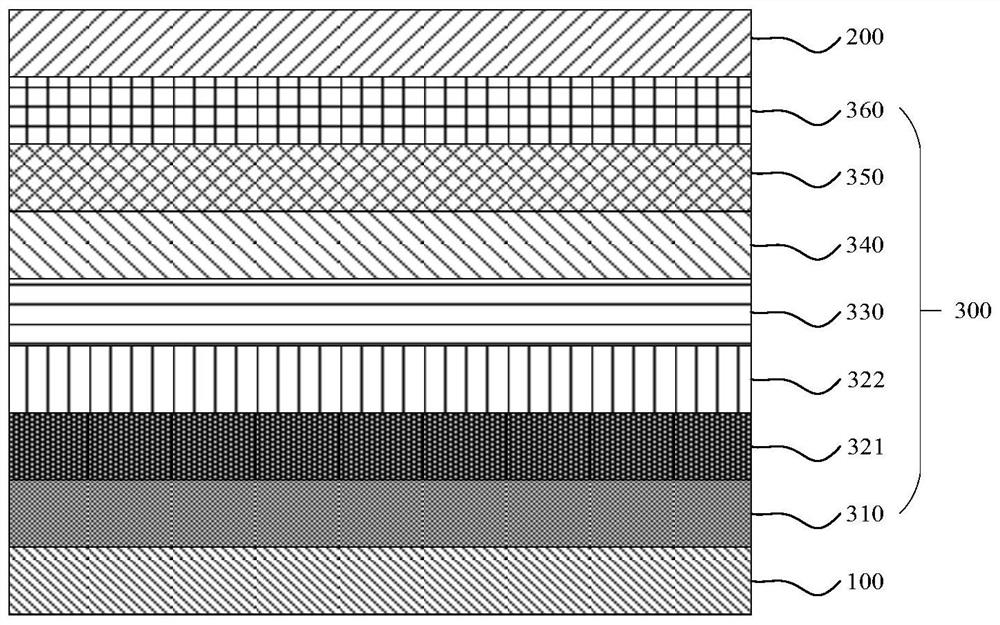

[0095] In a vacuum of 1×10 -5 Pa is deposited on a glass substrate with an anode of indium tin oxide (ITO) (thickness 100nm) by vacuum evaporation.

[0096] A compound HAT-CN was vapor-deposited on this substrate to form a hole injection layer (HIL) with a film thickness of 60 nm.

[0097] On the hole injection layer (HIL), compound NPB was then vapor-deposited to form a hole transport layer (HTL) with a thickness of 20 nm.

[0098] Compound 1 and Compound 2 were co-evaporated on the hole transport layer (HTL) to form an emitting layer (EML) with a thickness of 35 nm. The concentration of Compound 2 in the light-emitting layer (EML) was 97%, and the concentration of Compound B was 3%.

[0099] Compound A-2 and LiQ were co-evaporated on the emitting layer (EML), and the two materials were vaporized at the same rate to form an electron transport layer (ETL) with a thickness of 35 nm.

[0100] LiF was vapor-deposited on the electron transport layer (ETL) to form an electron in...

Embodiment 2-3

[0105] Using the compounds in Table 1 instead of Compound A-2, the same method as in Example 1 was used to fabricate an organic light-emitting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com