Lithiated functional polymer for lithium ion battery, and preparation method and application thereof

A technology of functional polymers and lithium-ion batteries, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as the inability to realize fast charging of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1PA

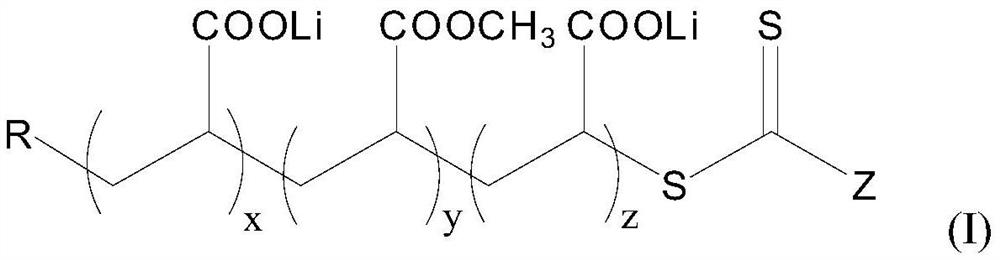

[0055] The preparation of preparation example 1PAALi-PMA-PAALi triblock polymer

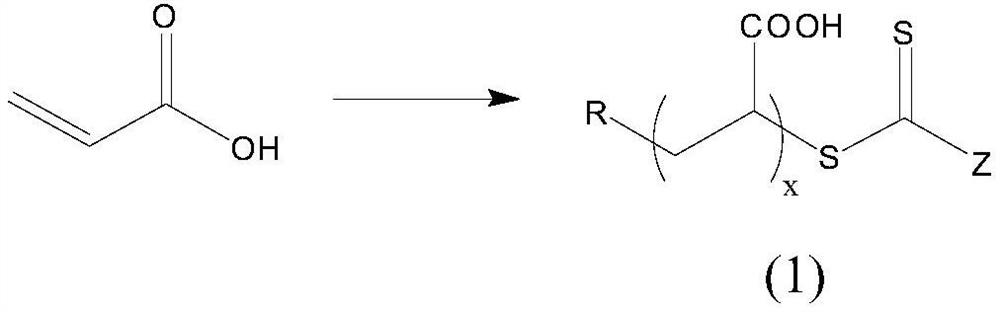

[0056] Step 1: Preparation of the first block polyacrylic acid (PAA)

[0057]

[0058] Mix 0.6 parts of RAFT reagent, 0.2 parts of initiator and 20 parts of acrylic acid monomer in 150 parts of deionized water solvent, stir and react at 70°C for 18 hours to obtain a reaction mixture containing the compound of formula (1'); wherein, RAFT reagent for Wherein, R is an acetate group; Z is a benzyl group; the initiator is potassium persulfate;

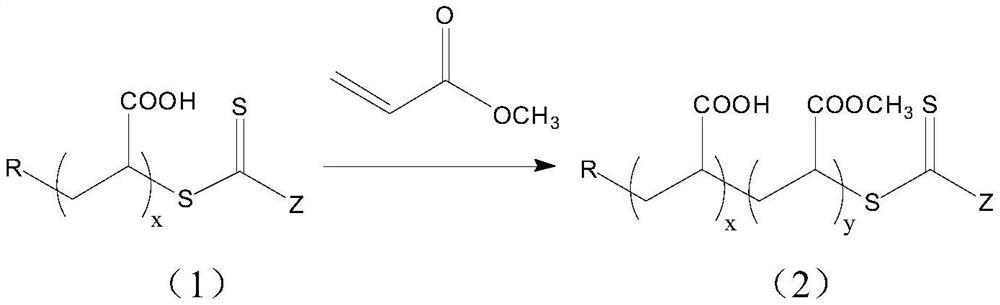

[0059] Step 2: Preparation of the second block polymethyl acrylate (PAA-PMA)

[0060]

[0061] Add 60 parts of methyl acrylate monomers to the reaction mixture obtained in step 1, then continue stirring at 70°C for 6h to obtain a reaction mixture containing the compound of formula (2');

[0062] Step 3: Preparation of the third block polyacrylic acid (PAA-PMA-PAA)

[0063]

[0064] Add 20 parts of acrylic acid monomers to the reaction mixture obt...

preparation example 2N

[0069] The preparation of preparation example 2NafionLi

[0070] Adjust the pH of the solution of perfluorosulfonic acid resin (Nafion-H) in deionized water to 5, then add 10% by mass fraction of 0.15mol / L lithium hydroxide aqueous solution, and carry out lithiation at 25°C for 4h; The resulting solution containing NafionLi was directly used to prepare the binder.

preparation example 3

[0071] The preparation of preparation example 3 binding agent

[0072] The PAALi-PMA-PAALi triblock polymer prepared in Preparation Example 1 and the solution containing NafionLi prepared in Preparation Example 2 were mixed in 100 parts of deionized water.

[0073] It is then used as a binder for making electrode pads.

[0074] Among them, the mass ratio of PAALi-PMA-PAALi triblock polymer to NafionLi, mixing temperature and mixing time are shown in the table below.

[0075] Adhesive sample PAALi-PMA-PAALi parts by mass Parts by mass of NafionLi Mixing temperature and time Binder 1 9 1 30℃24h binder 2 8 2 30℃24h binder 3 7 3 40℃24h binder 4 6 4 40℃24h Binder 5 5 5 50℃24h Binder 6 4 6 50℃24h Binder 7 3 7 50℃24h Binder 8 2 8 60℃24h Binder 9 1 9 60℃24h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com