A kind of antistatic wear-resisting polyurethane floor coating and preparation method thereof

A floor coating and polyurethane technology, applied in polyurea/polyurethane coatings, conductive coatings, anti-corrosion coatings, etc., can solve the problems of non-conductive performance, high construction cost, large construction thickness, etc., achieve excellent impact resistance performance, reduce construction cost, the effect of improving the strength of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

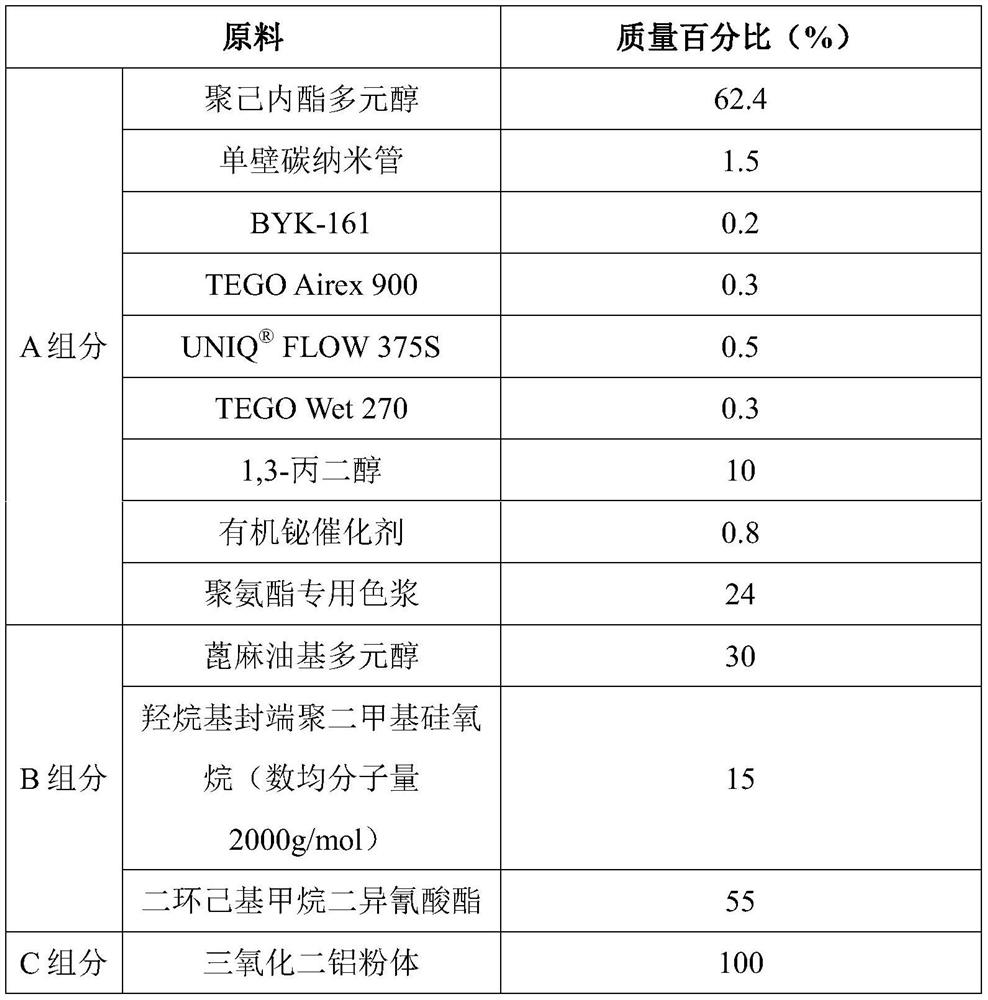

[0040] An antistatic wear-resistant polyurethane floor coating, the composition of which is shown in the following table:

[0041] Table 1 A composition table of antistatic wear-resistant polyurethane floor coating

[0042]

[0043] The preparation method of above-mentioned antistatic wear-resistant polyurethane floor coating comprises the following steps:

[0044]1) Add polycaprolactone polyol and 1,3-propylene glycol into the dispersion tank, adjust the stirring speed to 800r / min, stir for 15min, then add BYK-161, TEGO Airex 900, FLOW 375S, TEGO Wet 270 and organic bismuth catalyst, continue to stir for 10 minutes, then add single-wall carbon nanotubes, adjust the stirring speed to 1500r / min, stir for 40min, then add polyurethane special color paste, adjust the stirring speed to 800r / min, stir 20min, get A component;

[0045] 2) Add castor oil-based polyol and hydroxyalkyl-terminated polydimethylsiloxane to the reaction kettle, stir and heat up to 90°C, depressurize an...

Embodiment 2

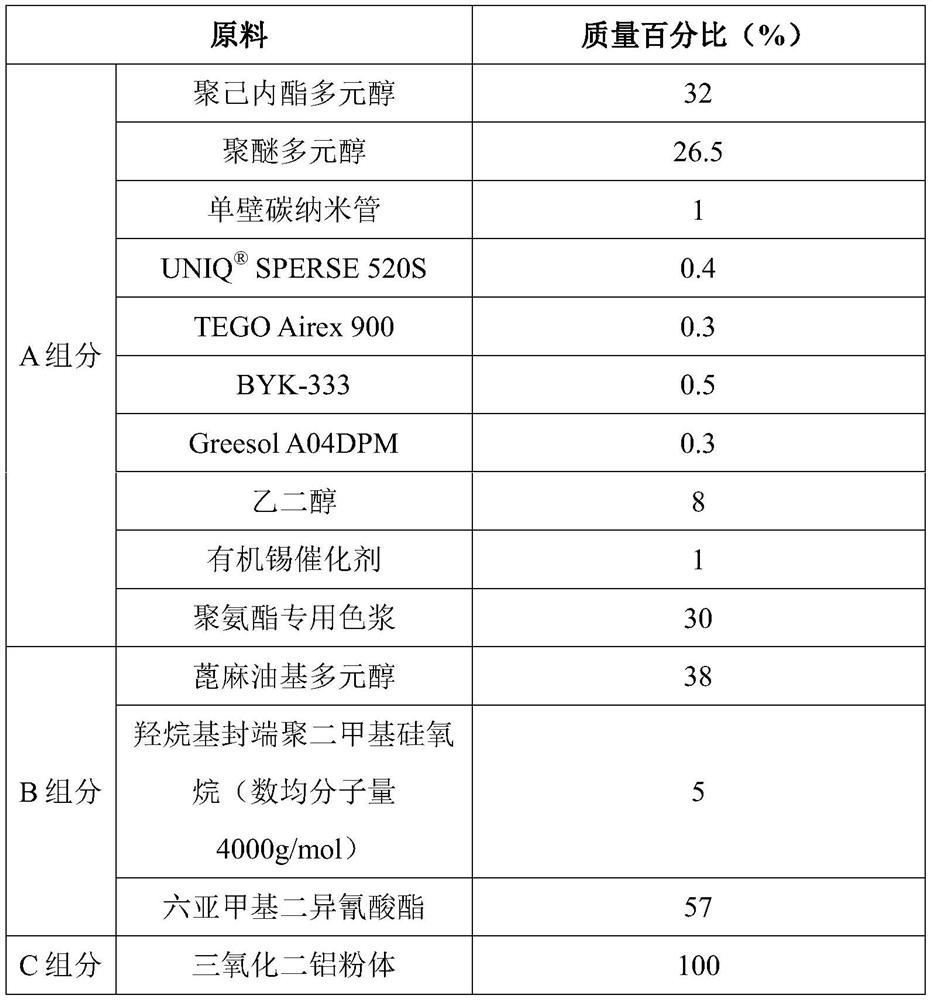

[0049] An antistatic wear-resistant polyurethane floor coating, the composition of which is shown in the following table:

[0050] Table 2 A composition table of antistatic wear-resistant polyurethane floor coating

[0051]

[0052] The preparation method of above-mentioned antistatic wear-resistant polyurethane floor coating comprises the following steps:

[0053] 1) Add polycaprolactone polyol, polyether polyol and ethylene glycol into the dispersion tank, adjust the stirring speed to 800r / min, stir for 15min, and then add SPERSE 520S, TEGO Airex 900, BYK-333, Greesol A04DPM and organotin catalyst, continue to stir for 10 minutes, then add single-walled carbon nanotubes, adjust the stirring speed to 1500r / min, stir for 40 minutes, then add polyurethane special color paste, adjust the stirring Rotate to 800r / min, stir for 20min to obtain component A;

[0054] 2) Add castor oil-based polyol and hydroxyalkyl-terminated polydimethylsiloxane to the reaction kettle, stir and...

Embodiment 3

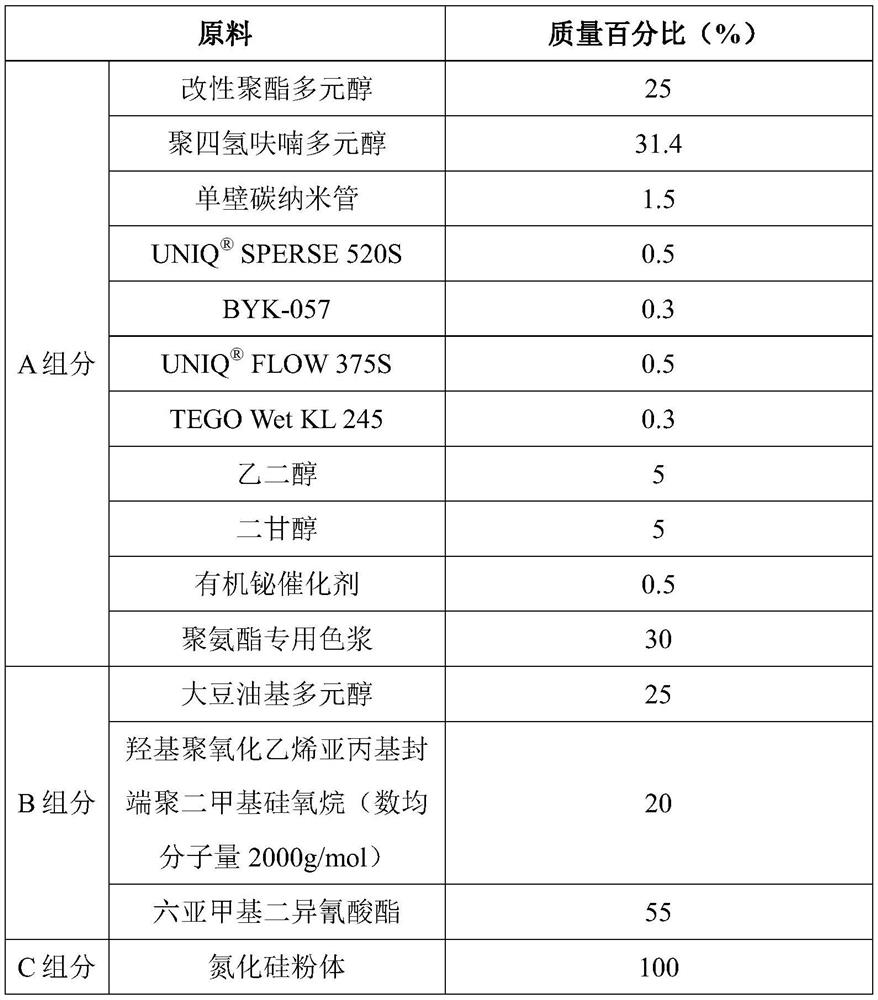

[0058] An antistatic wear-resistant polyurethane floor coating, the composition of which is shown in the following table:

[0059] Table 3 Composition table of a kind of antistatic wear-resistant polyurethane floor coating

[0060]

[0061] The preparation method of above-mentioned antistatic wear-resistant polyurethane floor coating comprises the following steps:

[0062] 1) Add modified polyester polyol, polytetrahydrofuran polyol, ethylene glycol and diethylene glycol into the dispersion tank, adjust the stirring speed to 800r / min, stir for 15min, and then add SPERSE 520S, BYK-057, FLOW 375S, TEGOWet KL 245 and organic bismuth catalyst, continue to stir for 10 minutes, then add single-walled carbon nanotubes, adjust the stirring speed to 1500r / min, stir for 40min, then add polyurethane special color paste, adjust the stirring speed to 800r / min, stir 20min, get A component;

[0063] 2) Add soybean oil-based polyol and hydroxypolyoxyethylene propylene-terminated polyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com