Underground cylinder reinforced concrete combined outer wall structure and construction method

A reinforced concrete and steel structure technology, applied in underwater structures, infrastructure projects, walls, etc., can solve the problems of high safety risk, complex construction environment and construction procedures, achieve good durability, reduce steel binding procedures, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

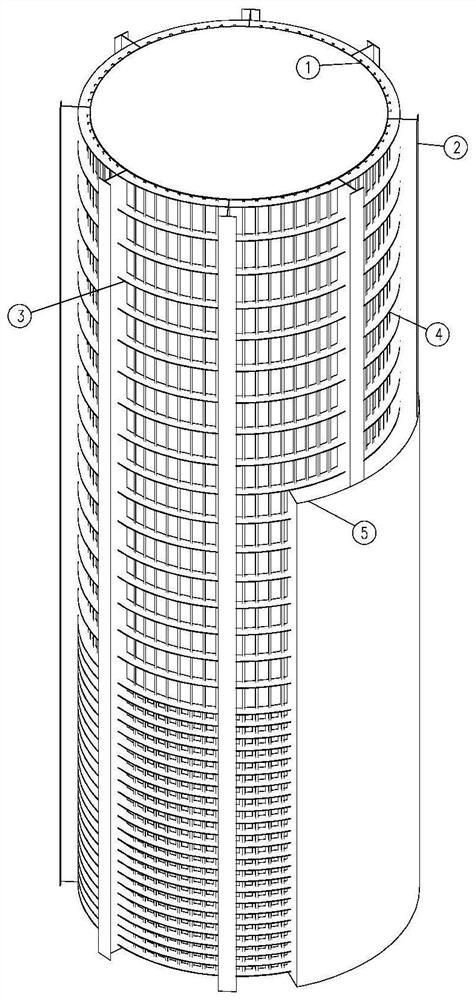

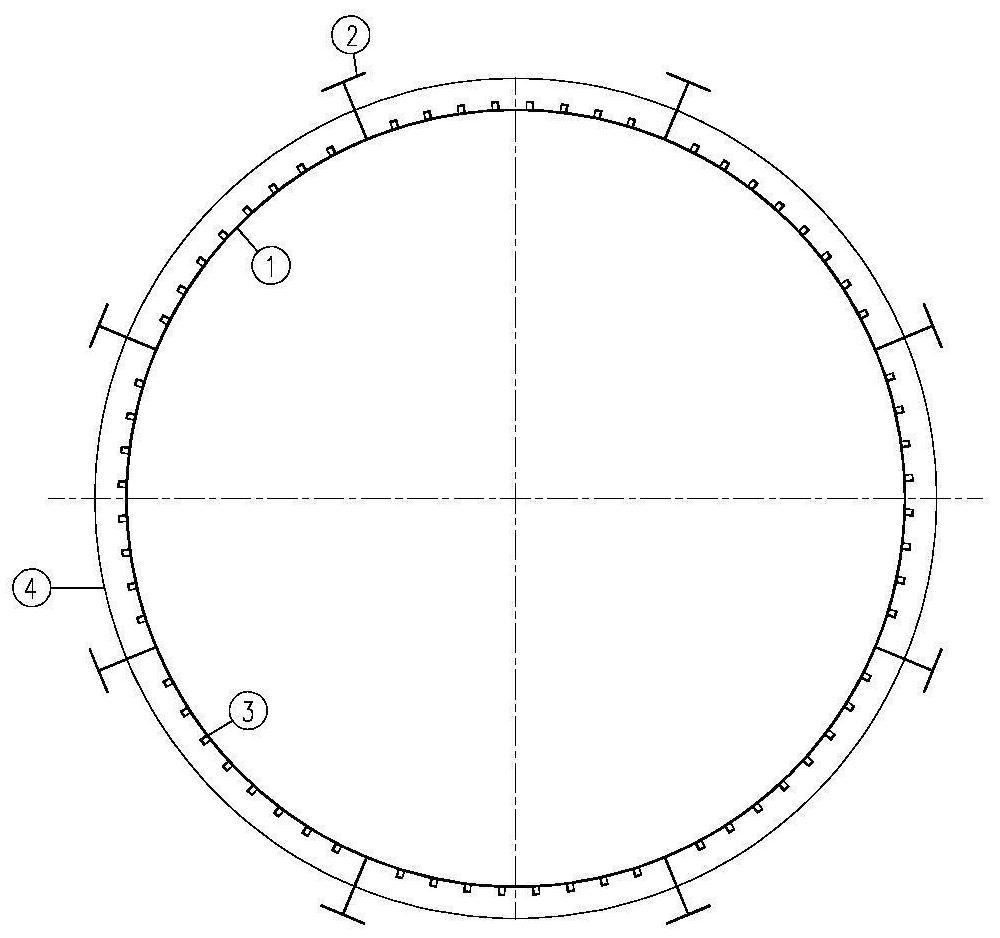

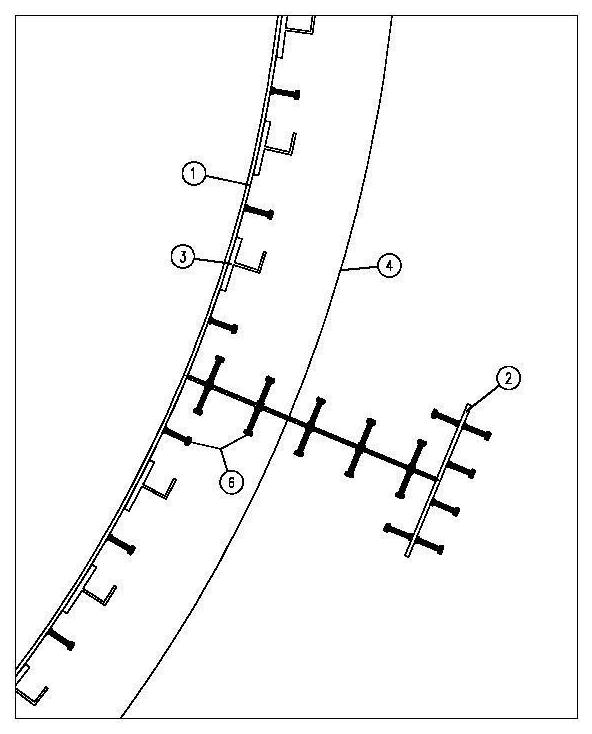

[0019] Such as Figure 1 to Figure 3 As shown, it is a schematic diagram of an underground cylindrical reinforced concrete composite exterior wall structure, including two parts: a cylindrical steel structure and a fiber reinforced concrete structure. The cylindrical steel structure includes a steel structure inner wall tube 1, T-shaped main ribs 2, angle steel Rib 3, circular steel plate 4 and stud shear connector 6, steel structure inner wall tube 1 is made of stainless steel outer side carbon structural steel composite steel plate, steel structure inner wall tube 1 outer side and T-shaped main rib 2 web plate and flange plate Stud shear connectors 6 are welded on both sides, angle steel vertical ribs 3 are welded on the outer side of steel structure inner wall tube 1, angle steel vertical ribs 3 and cylindrical steel structure are welded with steel plates as local reinforcement, steel structure inner wall tube 1 outer side is welded in the horizontal direction The steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com