Multifunctional closed tar residue collecting device and method

A technology for collecting device and tar residue, applied in the field of coking, can solve problems such as air pollution and environmental protection hazards, and achieve the effects of low cost, cost saving and great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

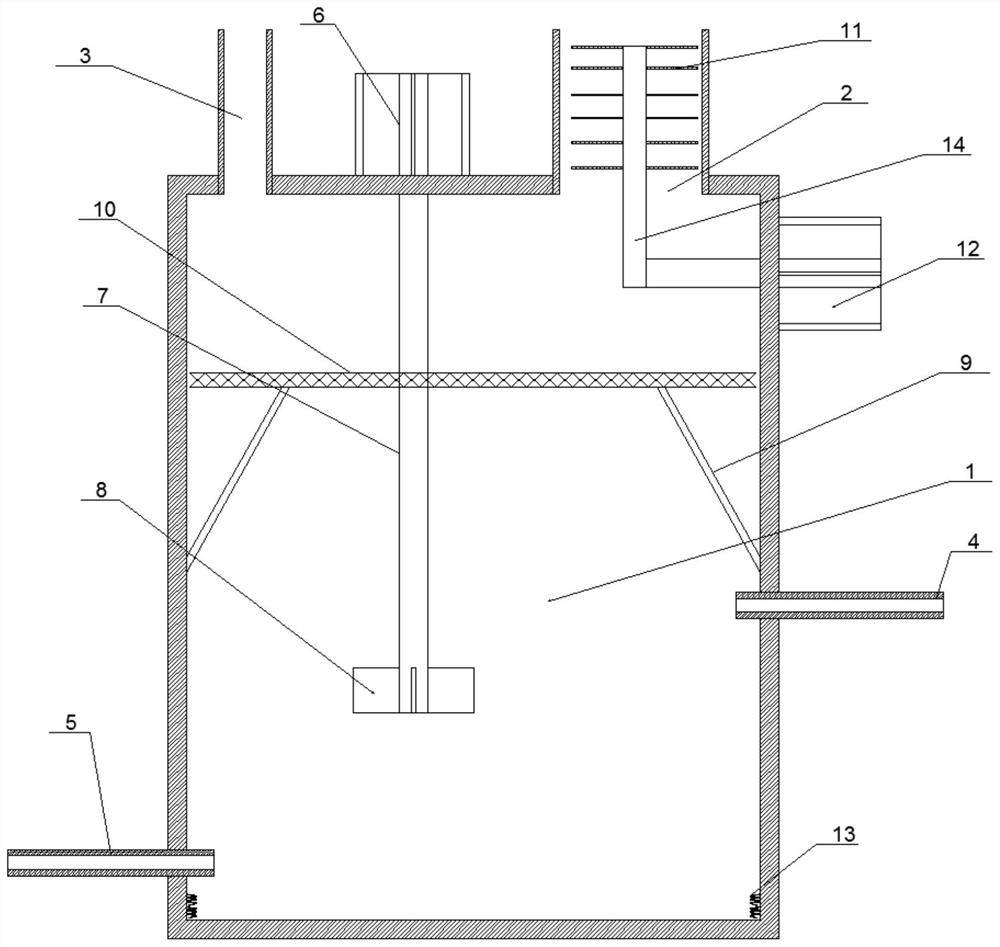

[0026] Close the tar residue outlet pipe 5, open the tar residue pipe 4, and inject tar into the tar residue collection tank 1, the tar amount reaches 1 / 3 of the tar residue collection tank height 1, and the tar amount in the tar residue collection tank 1 reaches 1 / 2. When the load of the first motor 6 is too large, it will cause overload and short circuit; open the exhaust gas collection pipe 3, after the injection of tar is completed, close the tar inlet pipe 4, and the heating coil 13 starts to heat the tar to 50°C; the tar residue is in Softening at this temperature, it will not be blocked when flowing out from the tar residue outlet pipe 5, and the subsequent tar residue treatment work is convenient; start the second motor 12, drive the second rotating shaft 14 to rotate, the blade 11 is rotated, and the tar residue is removed from the tar residue. The slag inlet pipeline 2 is put into the tar slag collection tank 1, the blade 11 cuts the tar slag, and the cut tar slag ent...

Embodiment 2

[0028] Close the tar residue outlet pipe 5, open the tar inlet pipe 4, and inject tar into the tar residue collection tank 1, the amount of tar reaches 1 / 4 of the height of the tar residue collection tank 1, and the amount of tar in the tar residue collection tank 1 reaches 1 / 2. When the load of the first motor 6 is too large, it will cause overload and short circuit, open the exhaust gas collection pipe 3, after the injection of tar is completed, close the tar inlet pipe 4, and the heating coil 13 starts to heat the tar, heated to 60 ℃, the tar residue is in Softening at this temperature, it will not be blocked when flowing out from the tar residue outlet pipe 5, and the subsequent tar residue treatment work is convenient; start the second motor 12, drive the second rotating shaft 14 to rotate, the blade 11 is rotated, and the tar residue is removed from the tar residue. The slag inlet pipeline 2 is put into the tar slag collection tank 1, the blade 11 cuts the tar slag, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com