Catalyst and method for heavy oil methanation modification and low-carbon aromatic hydrocarbon rich production simultaneously

A technology of low-carbon aromatics and catalysts, which is applied in the field of catalysts that are rich in low-carbon aromatics while adding methane to heavy oil. It can solve the problems of large hydrogen consumption, low impurity removal rate, and high cost of hydrogen sources, so as to increase added value , Increase the H/C ratio, improve the effect of crude oil properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

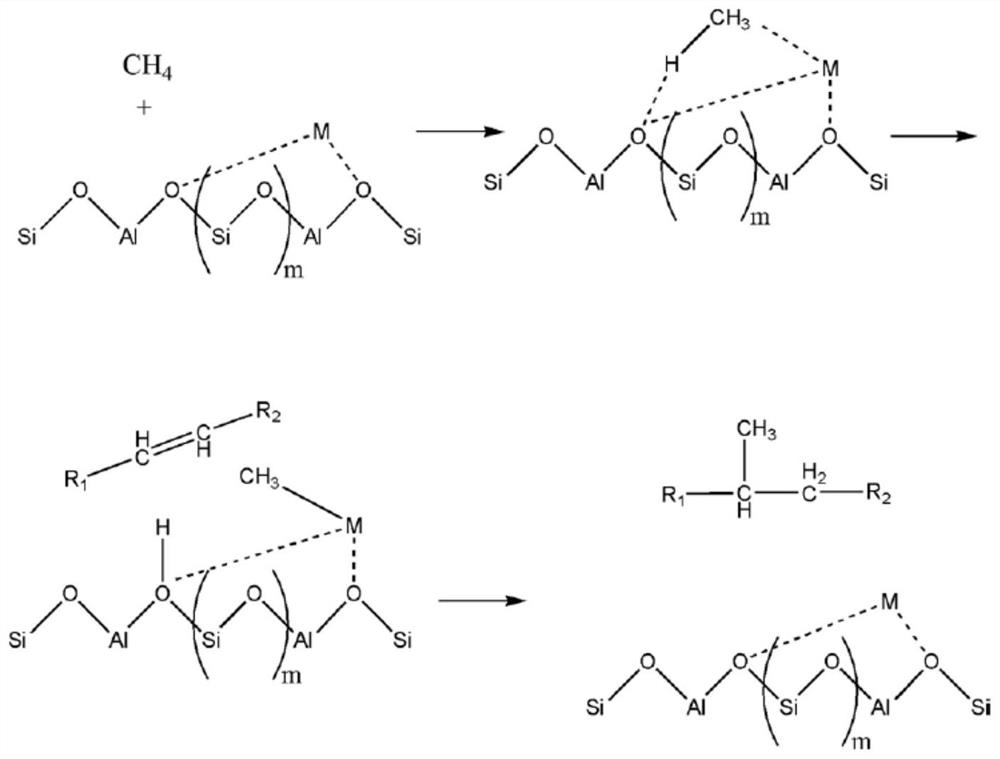

Method used

Image

Examples

Embodiment 1

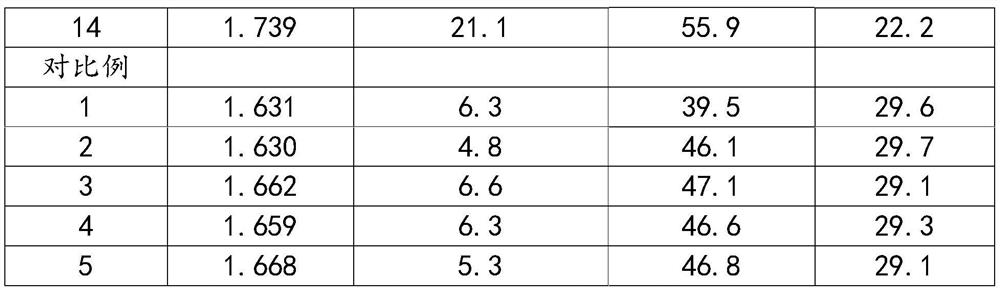

[0039] Saudi heavy oil at airspeed 1.0h -1 Entering the reactor, the reaction conditions are: temperature 360°C, pressure 5MPa, mass ratio of methane to Saudi heavy oil 0.05, HZSM-5 content in the catalyst 60%, Si / Al=10, binder SB powder content 38%, active metal The method of equal-volume impregnation is introduced, the content of active metal silver and gallium is 2%, and the catalyst is strip-shaped based on the total weight of the catalyst.

Embodiment 2

[0041] Same as Example 1, only the Saudi heavy oil is used at a space velocity of 1.5h -1 into the reactor.

Embodiment 3

[0043] With embodiment 1, Saudi heavy oil is 2.5h with space velocity -1 into the reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com