Automatic rotating tool and machining system and welding method adopting automatic rotating tool

An automatic rotation and processing system technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of cumbersome manual welding process, high labor intensity of operators, and low welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

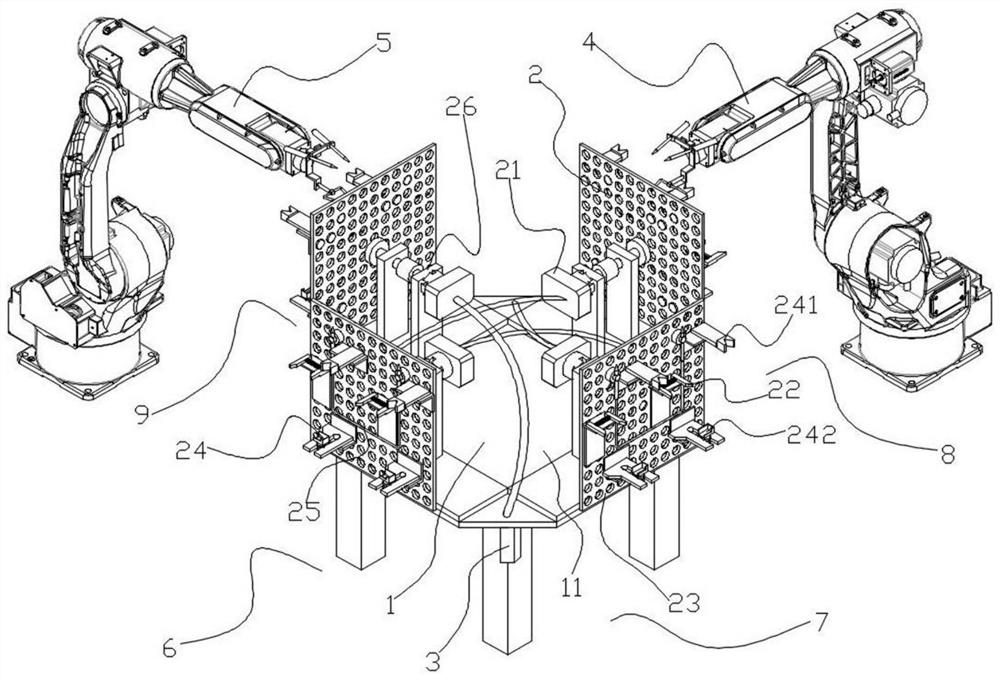

[0035] like Figure 1-2 As shown, this embodiment provides an automatic rotary tooling. The automatic rotary tooling in this embodiment is used to assemble and fix the muffler assembly before welding, and transport it to a preset position, so that the welding robot can easily fix it. Subsequent welding processing is performed, wherein the muffler assembly includes a muffler and a copper pipe. Specifically, the automatic rotating tooling in this embodiment includes a horizontal rotating assembly 1, a vertical rotating assembly 2 and a control system, wherein:

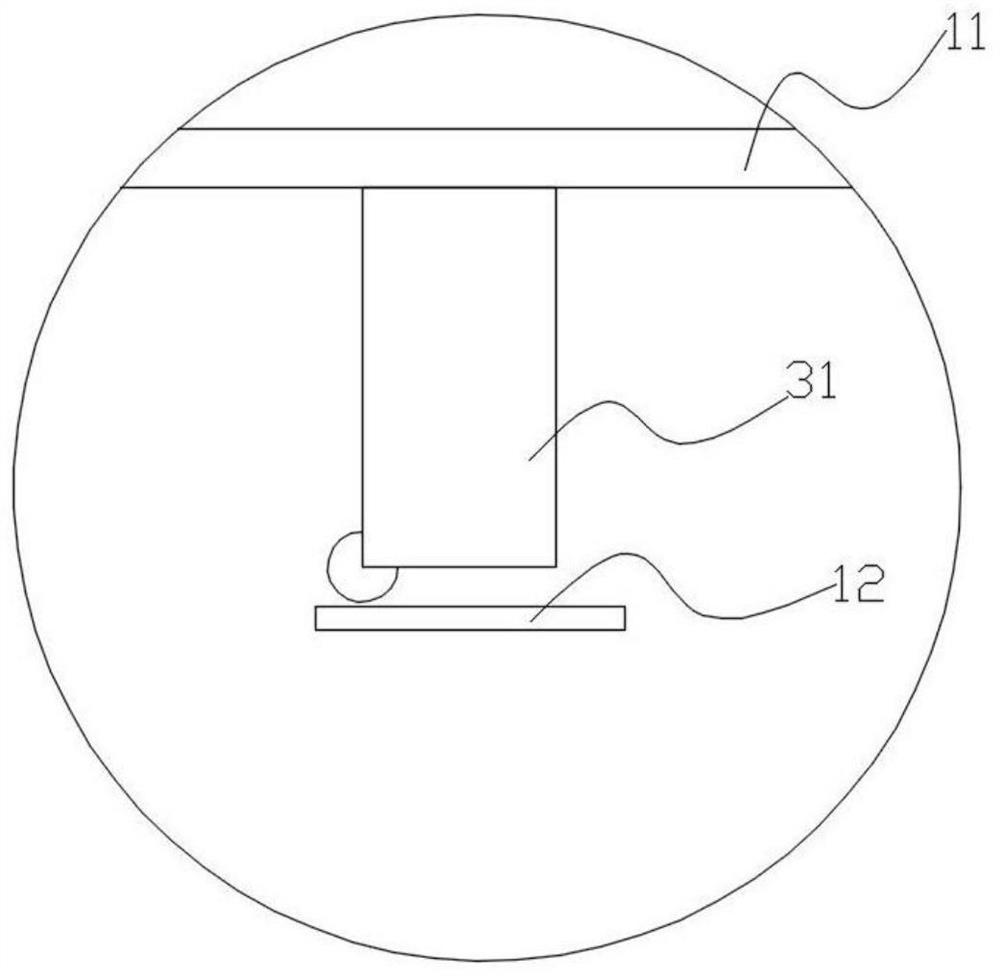

[0036] The horizontal rotation assembly 1 includes a worktable 11 and a first driving mechanism drivingly connected to the worktable 11, and the first driving mechanism is used to drive the worktable 11 to rotate horizontally. The first driving mechanism in this embodiment is a rotary motor, and the drive output end of the rotary motor is connected to the bottom plane of the workbench 11. When the rotary motor rotates, ...

Embodiment 2

[0055] like figure 1 As shown, this embodiment provides a processing system, which adopts the automatic rotary tooling provided in Embodiment 1.

[0056] Preferably, the automatic rotary processing system in this embodiment also includes a processing robot, one or more processing robots are set, and each processing robot corresponds to a station setting, which reduces the labor intensity of the welding operator and automates the processing of the workpiece. At the same time, the processing quality and processing efficiency can also be improved.

[0057] The processing robot in this embodiment is a welding robot, which is used to weld the muffler assembly. The number of welding robots is two, that is, the first welding robot 4 and the second welding robot 5 respectively, wherein the first welding robot 4 The setting position of the second welding robot 5 corresponds to the first welding station 8 in front of the workbench 11, and is used to weld the first group of welding spot...

Embodiment 3

[0063] like Figure 1-2 As shown, this embodiment provides an automatic rotation welding method, using an automatic rotation processing system in Embodiment 1 and / or Embodiment 2, and the automatic rotation welding method in this embodiment is used to weld the muffler assembly , wherein, the muffler assembly has two sets of solder joints, these two sets of solder joints are the first set of solder joints and the second set of solder joints below it respectively, the first set of solder joints has 4 in total, and the second set of solder joints There are 2 in total, the welding of the first set of spot welding is the first welding process, and the welding of the second set of spot welding is the second welding process.

[0064] When the parts to be welded are fixed on the vertical rotation assembly 2, the automatic rotation processing system automatically implements the following operations:

[0065] S1: Control the horizontal rotation assembly 1 to rotate the first preset ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com