Novel coking wastewater ammonia nitrogen component removal equipment

A coking wastewater and removal technology, which is applied in the direction of water pollutants, separation methods, and dispersed particle separation, can solve the problems of poor separation effect of ammonia nitrogen removal tower, achieve high removal ratio, good removal effect, and overall The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

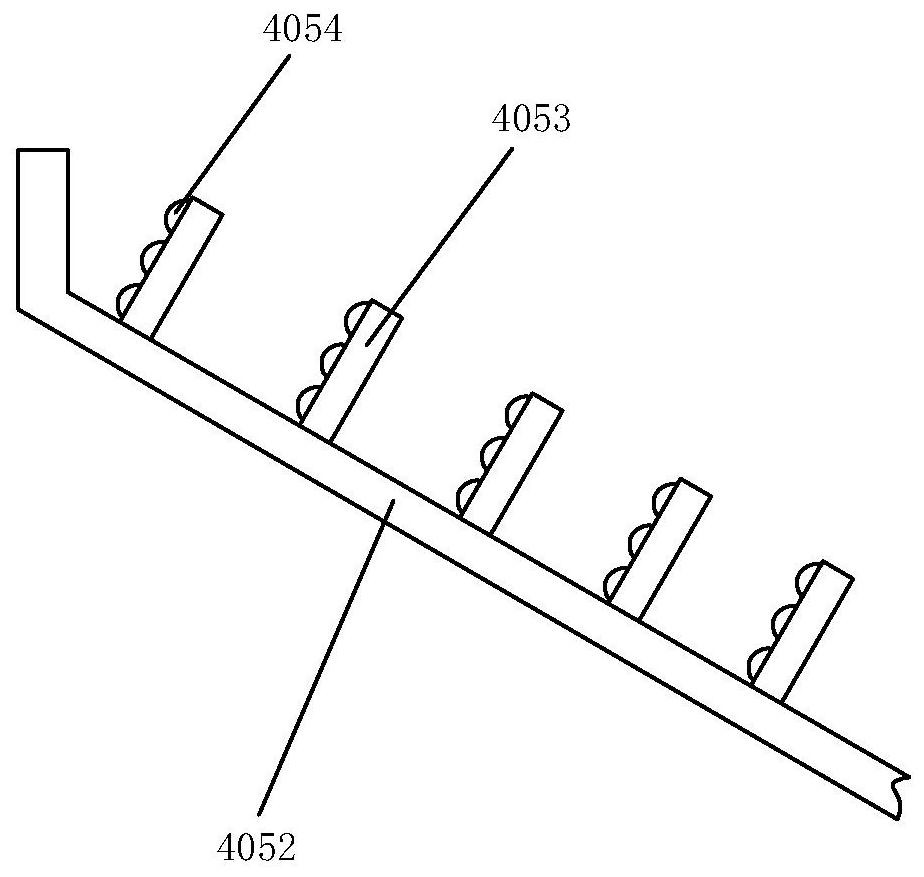

[0028] A new type of coking wastewater ammonia nitrogen component removal equipment, such as figure 1 As shown, it includes a filter device 100, an alkaline adjustment device 200, a heating device 300, a removal device 400 and a waste gas treatment device 500. The solid impurities are filtered out. Then, the coking wastewater flows into the alkaline adjusting device 200, and the pH value of the coking wastewater is raised by adding alkaline liquid or other alkaline regulators to make it strongly alkaline. The coking wastewater whose pH value has been raised is then heated by the heating device 300 to make the wastewater have a certain temperature, which facilitates the release of ammonia nitrogen gas in the wastewater. Then it flows into the removal device 400. The rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com