Method for enriching and separating perchloroethylene (PCE) dechlorinating bacteria and application

A technology for enriching tetrachloroethylene and tetrachloroethylene, which is applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc. effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 High-efficiency enrichment of tetrachlorethylene complete dechlorination mixed bacteria from urban black and odorous water

[0064] 1. Experimental method

[0065] (1) Enrichment method

[0066] Take 5 mL of sediment samples collected from urban PCE-polluted black and odorous water, and inoculate them into DL-sodium lactate anaerobic dechlorination liquid medium with 1 mM PCE as the only electron acceptor (its formula is shown in Table 1). The impact of oxygen, to ensure the complete anaerobic culture environment, add excess Na to the medium 2 S. The culture temperature was 30°C, and the dechlorination of PCE was monitored at the same time to observe whether it produced ethene. After the PCE in the culture solution is completely dechlorinated, maintain the same culture conditions, carry out two subcultures until there is no obvious sediment residue in the culture solution to obtain the complete dechlorination mixed bacteria of tetrachlorethylene.

[0067] ...

Embodiment 2

[0085] Example 2 Isolate Geobacter Geobacter from PCE dechlorination to cis-DCE process

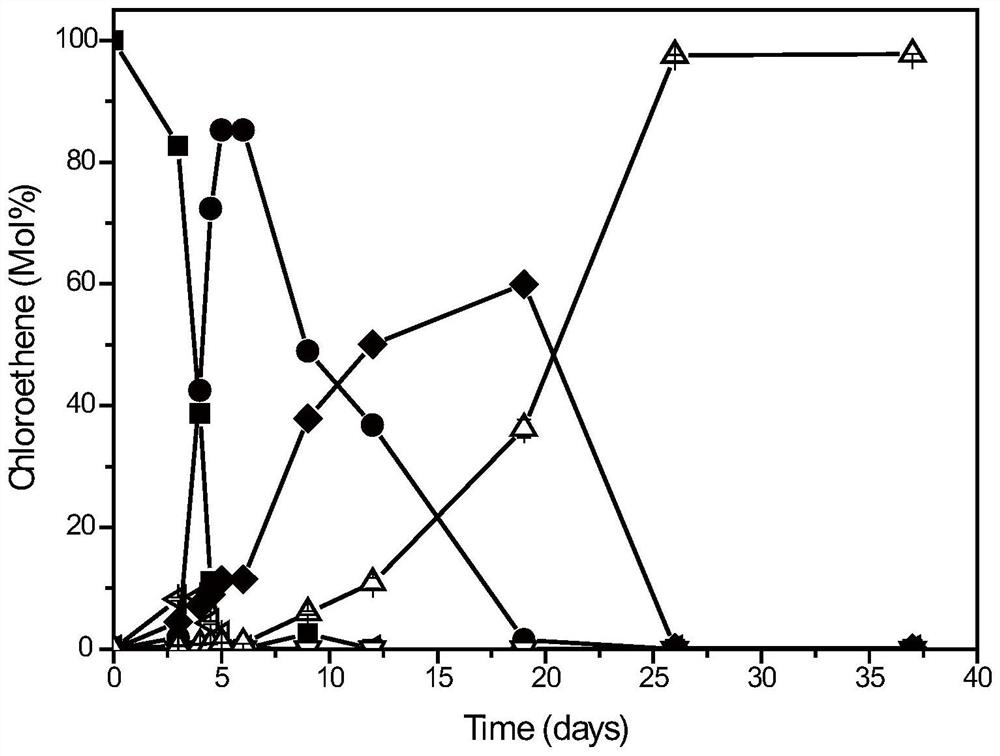

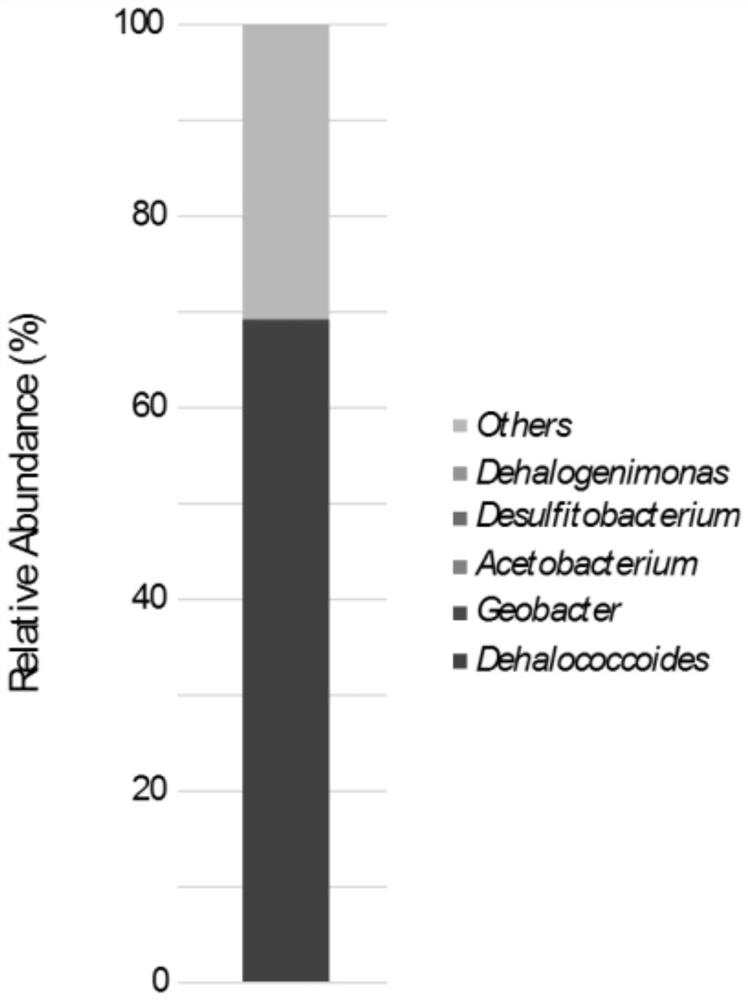

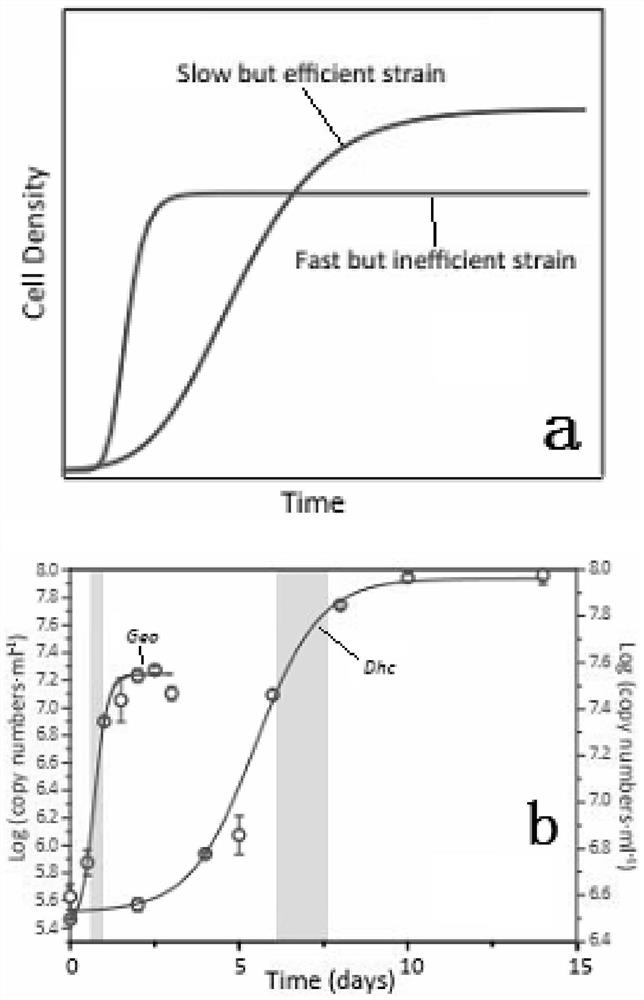

[0086] From figure 1 It can be seen that the complete dechlorination process of PCE is divided into two stages, the latter stage can only be completed by Dehalococcoides, and in the first stage PCE dechlorination speed is faster (0.4mM Cl - / day), and no obvious trans-DCE (partial Dehalococcoides dechlorination product) was observed, which proved that non-Dehalococcoides must participate in the dechlorination of PCE; through community analysis, it was found that there were other PCE dechlorination microorganisms in the mixed bacteria— Geobacter (0.3%). Since Geobacter and Dehalococcoides have similar substrate utilization in the anaerobic dechlorination process, they cannot be effectively separated. In order to obtain the PCE rapid dechlorination microorganism Geobacter at this stage, a new separation method must be designed.

[0087] 1. Separation and purification method

[0088] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com