Aluminum foil and preparation method thereof

A technology of aluminum foil and aluminum liquid, applied in metal rolling, electrochemical generators, electrical components, etc., can solve the problems of reducing the ductility of aluminum foil, unfavorable aluminum foil rolling and processing, etc., to prevent broken strips, high tensile strength, good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

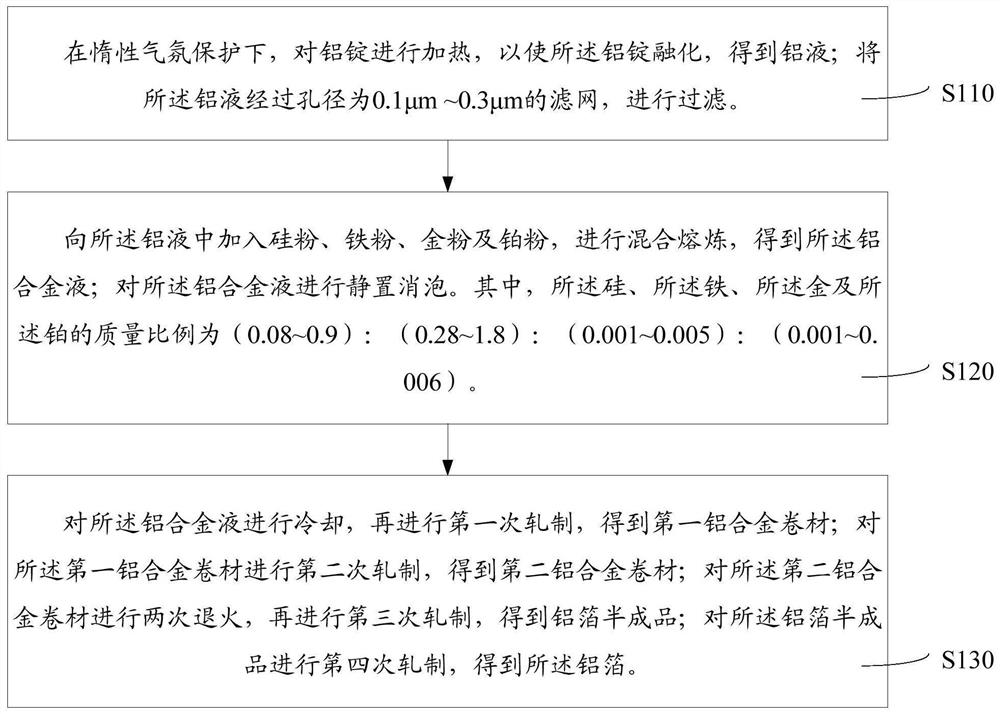

Method used

Image

Examples

Embodiment approach

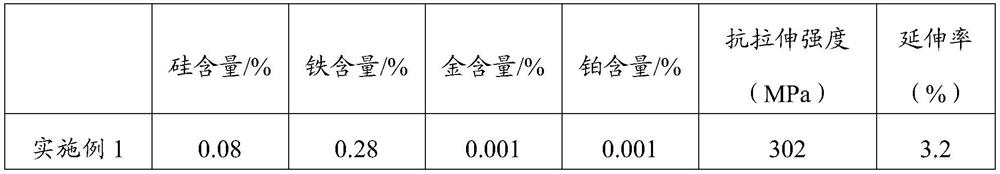

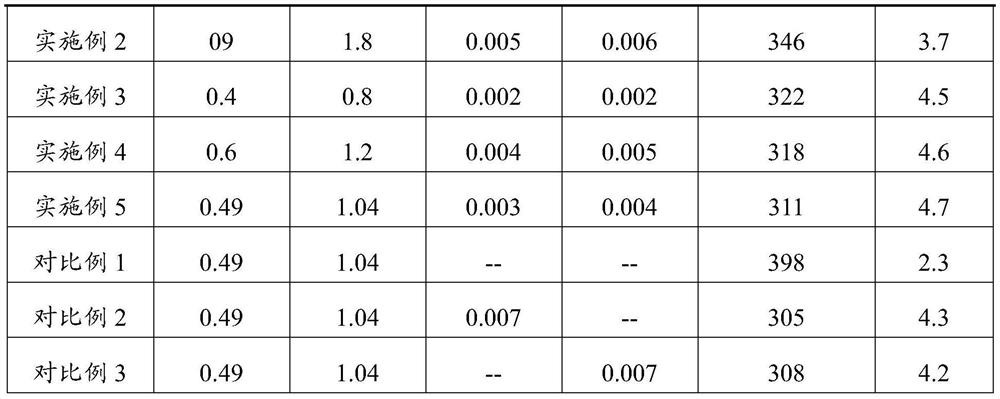

[0027] In one embodiment, an aluminum foil contains the following elements by weight percentage: 0.08%-0.9% of silicon, 0.28%-1.8% of iron, 0.001%-0.005% of gold, and 0.001%-0.006% of platinum. The aluminum foil also contains unavoidable impurities.

[0028] It should be noted that, on the one hand, by adding a certain amount of silicon and iron to aluminum, it is helpful for the formation of dendrite spacing in aluminum foil, the particles of the intermediate metal compound in aluminum foil are small, the composition segregation is large, and the degree of supersaturation of solute elements in the solid solution is greatly increased. Improve, improve work hardening of aluminum materials, large deformation resistance, improve tensile strength.

[0029] On the one hand, gold is the most malleable metal, and a gram of gold can be punched into a square meter sheet, or an ounce of gold can be punched into 300 square feet. Gold leaf can even be thinned to translucency. Therefore,...

Embodiment 1

[0064] S111, under the protection of an inert atmosphere, heat the aluminum ingot at a temperature of 1800° C. to melt the aluminum ingot to obtain molten aluminum; pass the molten aluminum through a high-temperature-resistant silicon-based filter with a pore size of 0.1 μm net to filter.

[0065] S121, adding 0.08% silicon powder, 0.28% iron powder, 0.001% gold powder and 0.001% platinum powder to the aluminum liquid, and performing mixing and melting to obtain the aluminum alloy liquid; standing and defoaming the aluminum alloy liquid .

[0066] S131, cooling the aluminum alloy liquid, the cooling temperature is 500° C.; then rolling the first aluminum alloy coil with a rolling machine to obtain the first aluminum alloy coil; performing the first aluminum alloy coil on the first aluminum alloy coil Rolling twice to obtain a second aluminum alloy coil; performing two annealing on the second aluminum alloy coil, wherein the temperature of the first annealing is 435° C., and t...

Embodiment 2

[0068] S112, under the protection of an inert atmosphere, heat the aluminum ingot, the heating temperature is 2000°C, so as to melt the aluminum ingot to obtain molten aluminum; pass the molten aluminum through a high-temperature-resistant silicon-based filter with a pore size of 0.3 μm net to filter.

[0069] S122, adding 0.9% silicon powder, 1.8% iron powder, 0.005% gold powder and 0.006% platinum powder to the aluminum liquid, and performing mixing and melting to obtain the aluminum alloy liquid; standing and defoaming the aluminum alloy liquid .

[0070] S132, cooling the aluminum alloy liquid, the cooling temperature is 700°C; and then rolling the first aluminum alloy coil with a rolling machine to obtain the first aluminum alloy coil; performing the first aluminum alloy coil on the first aluminum alloy coil Rolling twice to obtain a second aluminum alloy coil; performing two annealing on the second aluminum alloy coil, wherein the temperature of the first annealing is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com