Online quality detection control method and device for ultrasonic welding machine

An ultrasonic welding, detection and control technology, which is applied in special data processing applications, instruments, data processing applications, etc., can solve the problems of difficult to judge the soundness of ultrasonic welding of power batteries and large inspection limitations, and achieve multi-dimensional and Multiple inspections, guaranteed welding quality, and the effect of ensuring the accuracy and correctness of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

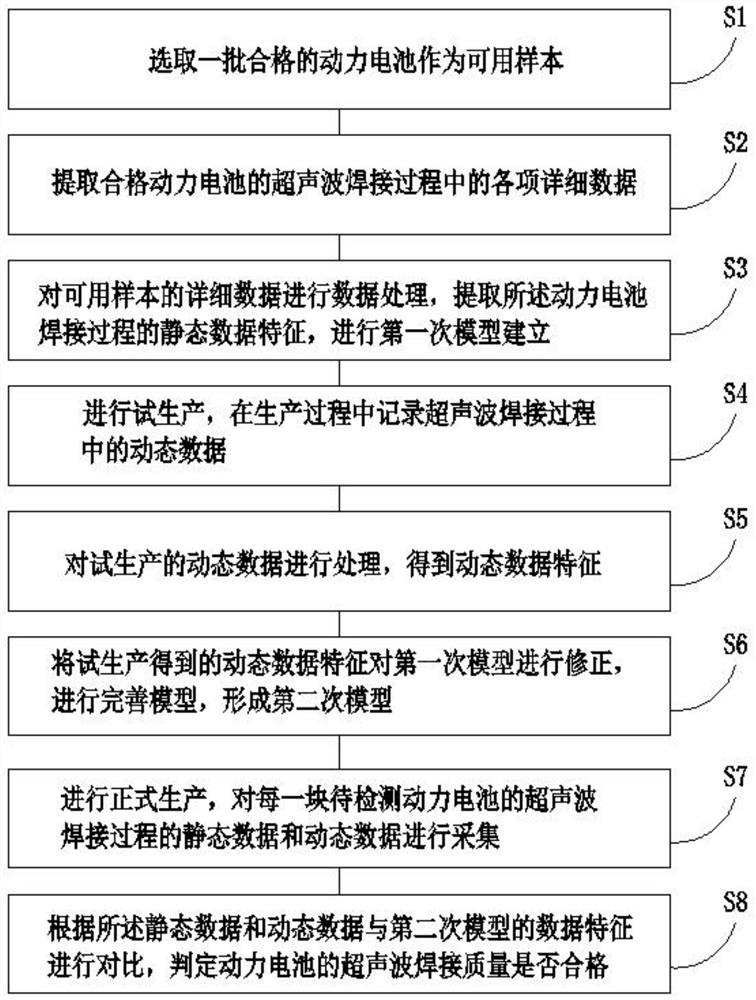

[0026] Please refer to figure 1 , the figure shows a schematic diagram of the steps of an online quality inspection and control method for an ultrasonic welding machine. This embodiment provides an online quality inspection and control method for an ultrasonic welding machine, including:

[0027] Step S1, select a batch of qualified power batteries as available samples, and it is not enough to judge the welding quality of the power battery to be tested by using only one ultrasonic welding data, there will be various deviations, so it is necessary to pass a set of Qualified power batteries that have been welded are used as samples. All samples must be able to pass the insertion force failure test and meet the national standards, so that the samples can be reliable and the first model obtained can meet the requirements.

[0028] Step S2, extract the detailed data of the ultrasonic welding process of the qualified power battery. The detailed data of the sample has been recorded i...

Embodiment 2

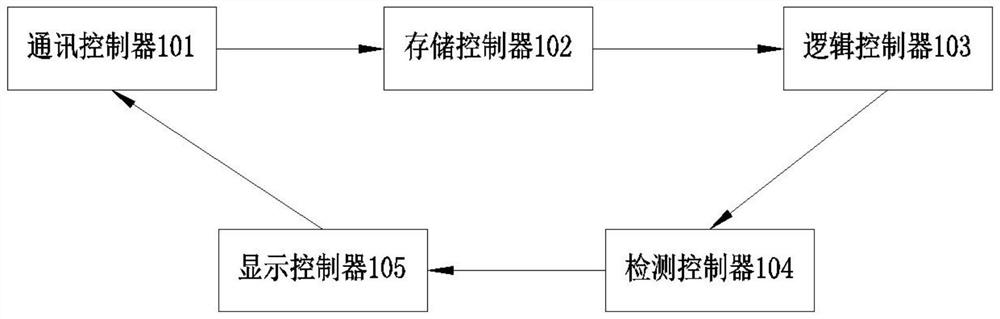

[0045] Please refer to figure 2 ,exist figure 2 shows an online quality inspection and control device for an ultrasonic welding machine, including:

[0046] The communication controller 101 is used to collect dynamic data and static data during the ultrasonic welding process of the power battery to be tested to obtain dynamic data and static data.

[0047] The storage controller 102 is connected with the communication controller 101 and used for storing the dynamic data and the static data.

[0048] The logic controller 103 is connected with the storage controller 102 and configured to process the dynamic data and the static data.

[0049] The detection controller 104 is connected with the logic controller 103 and used for judging whether the power battery to be tested is qualified according to the static data and the dynamic data.

[0050] The display controller 105 is connected with the detection controller 104 and is used for accurately displaying the determination res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com