Concentration production device for mirabilite-method barium sulfate byproduct sodium sulfide

A production device, sodium sulfide technology, applied in the direction of alkali metal sulfide/polysulfide, separation method, chemical instrument and method, etc., can solve the problems of labor occupation, pipe plugging, high energy consumption of multi-effect evaporation, etc. Scale, improve the effect of concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is:

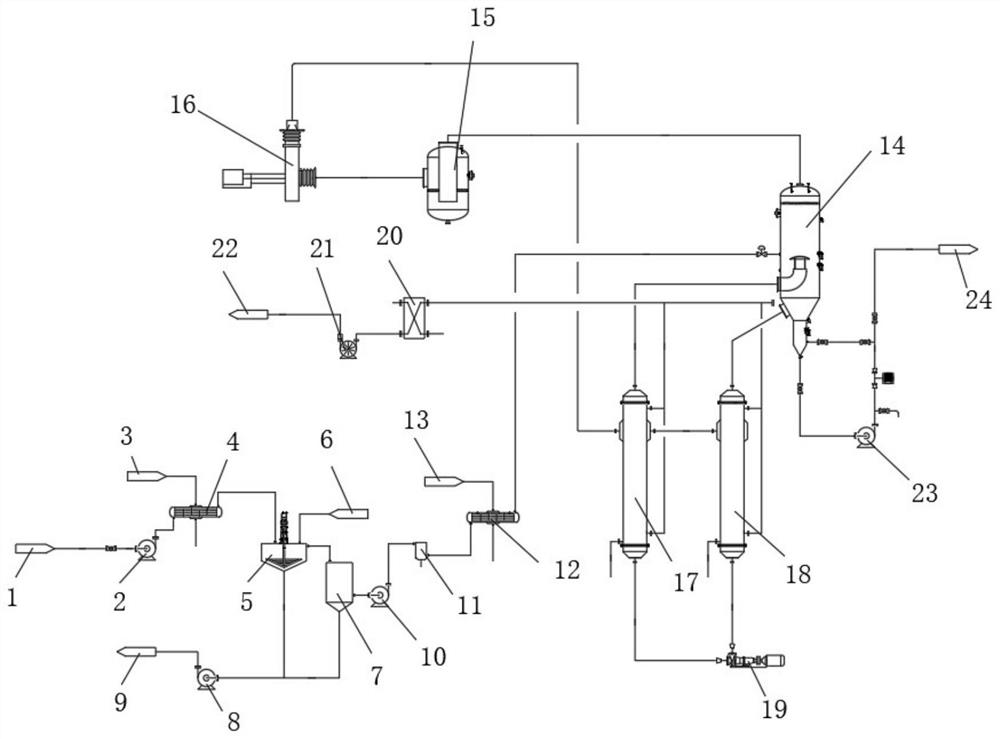

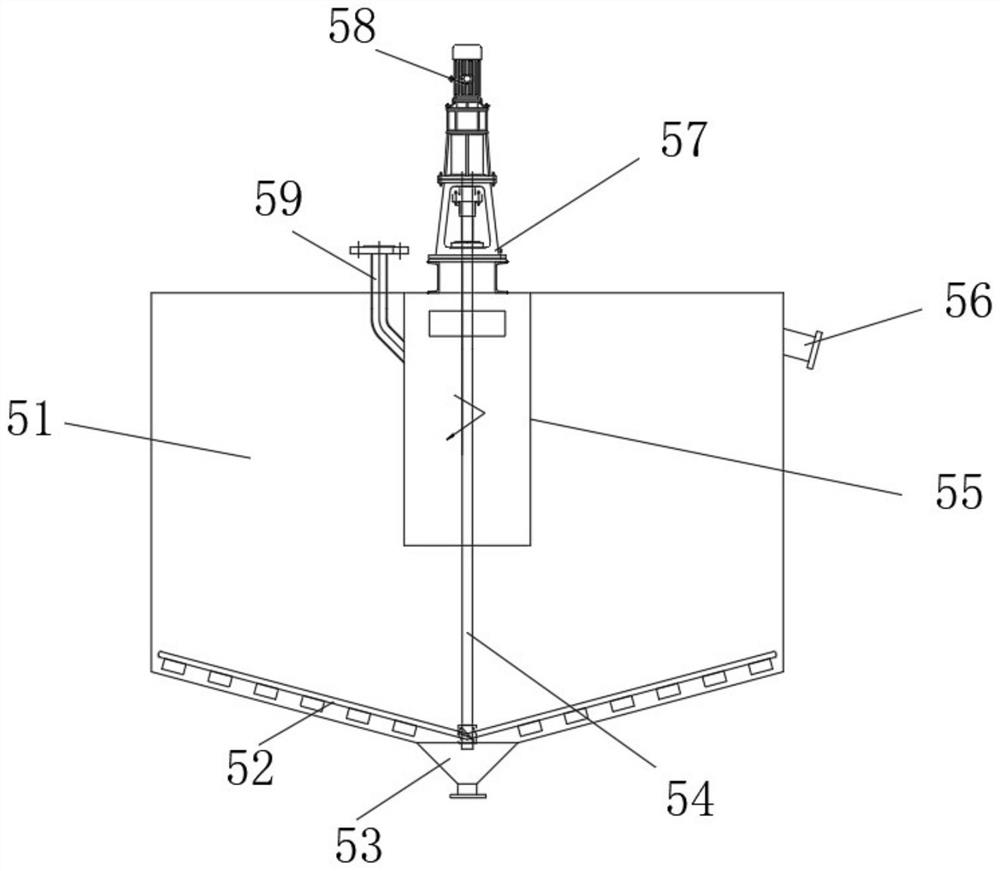

[0020] see Figure 1-2 As shown, the concentrated production device of barium sulfate by-product sodium sulfide by Glauber’s salt method, sodium sulfide solution inlet 1, feed pump 2, primary preheater 4, primary settling tank 5, secondary settling tank 7, transfer pump 10 , microfilter 11, secondary preheater 12, and separator 14 are sequentially connected by pipelines; primary preheater 4 heats through heat source inlet 3; primary preheater 4 heats sodium sulfide solution; secondary preheater The device 12 is connected with the second steam inlet 13; the first evaporation heating chamber 17 and the second evaporation heating chamber 18 form a closed loop with the separator 14 in turn; the first evaporation heating chamber 17 and the second evaporation heating chamber 18 are The sodium sulfide solution is heated and evaporated, and the forced circulation pump 19 pushes the sodium sulfide solution to return to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com