Harmless dangerous waste carbon energy-saving activation and regeneration system

A regeneration system, harmless technology, applied in filter regeneration, combustible gas purification, chemical instruments and methods, etc., can solve the problems of high energy consumption, bag filter is not resistant to high temperature, etc., achieve low energy consumption, activation reaction Short time, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

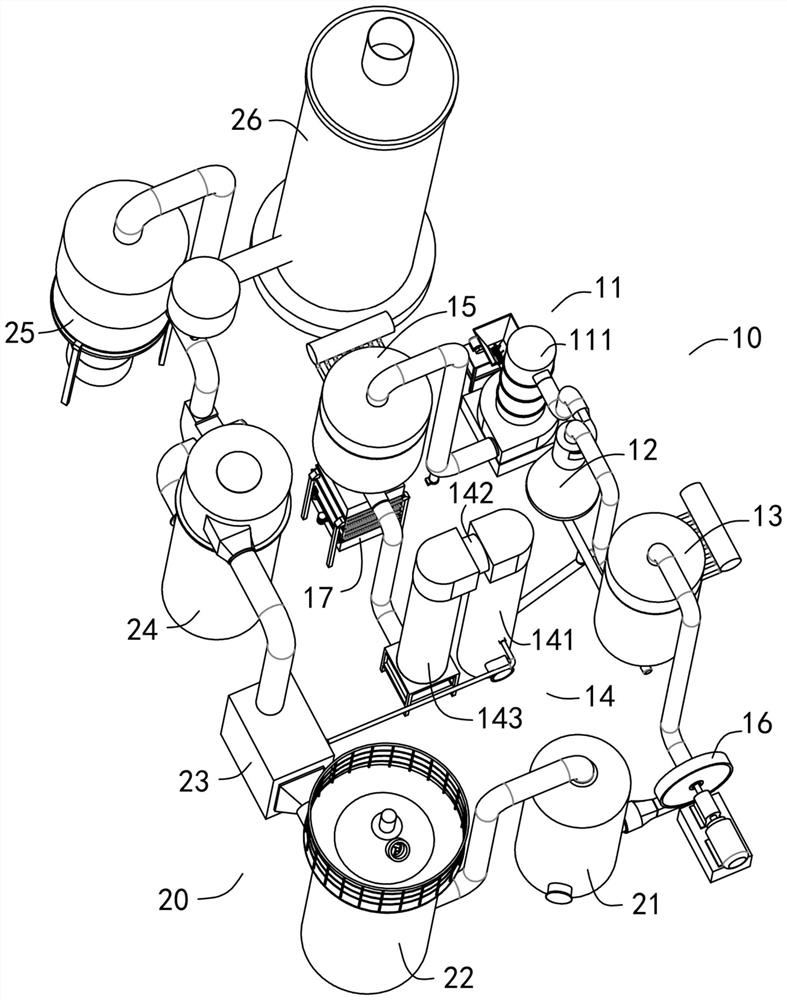

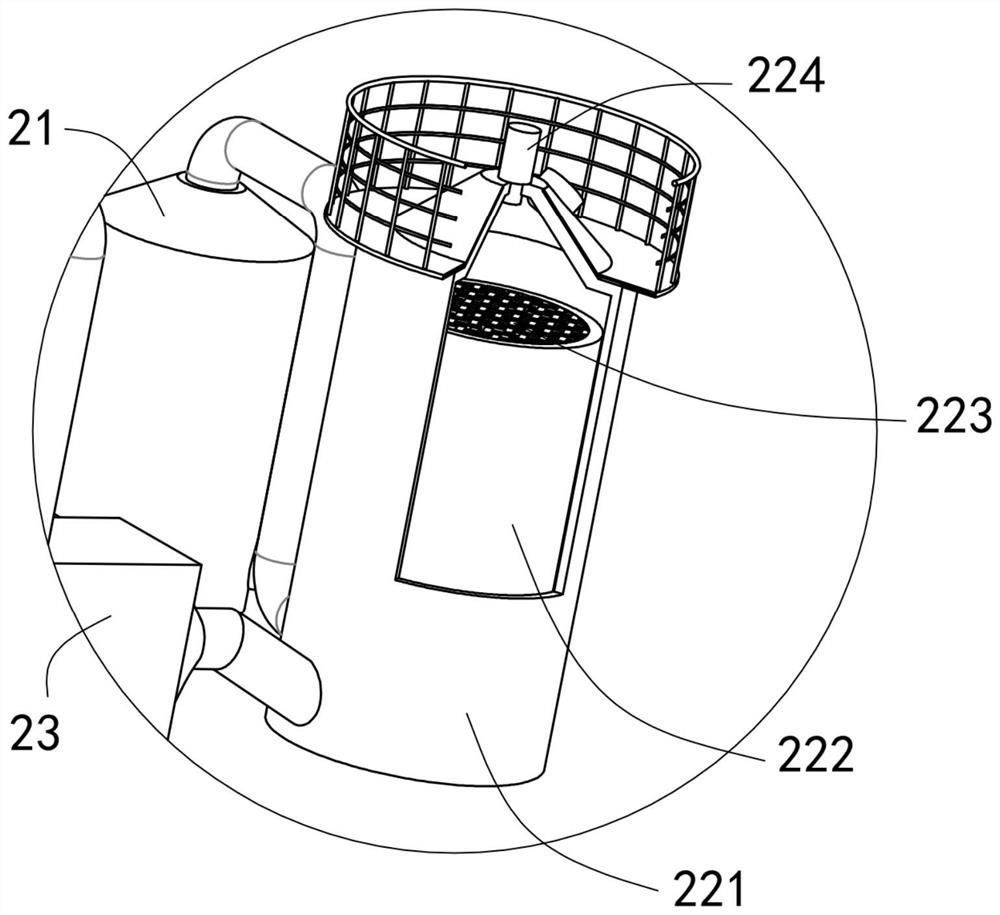

[0026] see figure 1 and figure 2, the embodiment of the present invention provides a harmless hazardous waste carbon energy-saving activation regeneration system, including a waste carbon regeneration unit 10, a tail gas treatment unit 20, the waste carbon regeneration unit 10 includes a flash dryer 11, a cyclone dust collector 12, a second Two metal film bag filter 13, dynamic regeneration furnace 14, the first metal film bag filter 15, negative pressure fan 16, flash drying machine 11 comprises flash drying body 111, is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com