Magnetic control negative pressure enhanced adhesion device capable of imitating octopus sucker

A suction cup and adhesion technology, applied in the field of bionic structural intelligent devices, can solve the problems of large motion resistance, increased suction cup volume, and high adhesion and desorption cost, and achieve the effects of improving environmental adaptability, improving adhesion effect, and easily realizing desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

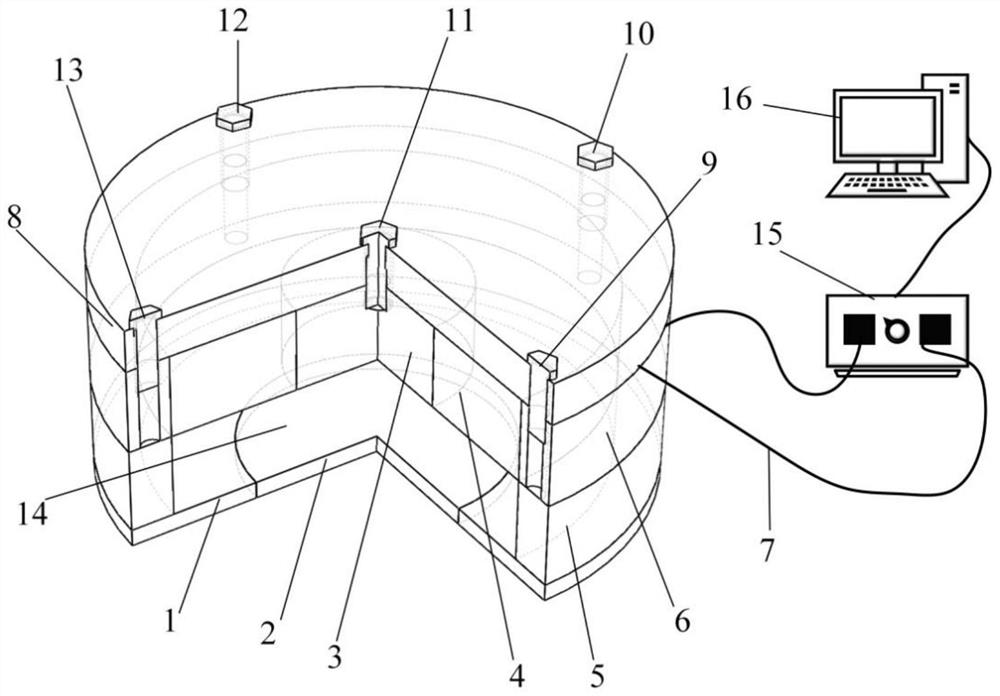

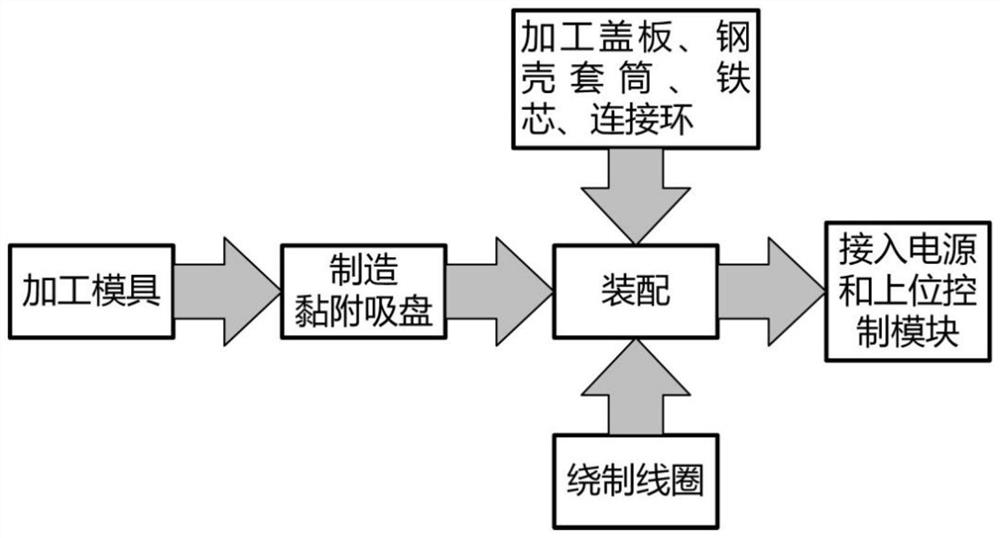

[0044] The invention relates to an intelligent structural device, specifically a magnetically controlled negative pressure enhanced adhesion device imitating an octopus suction cup, which can be mainly divided into two parts: the adhesion suction cup and the regulating electromagnet. The adhesion suction cup is used to realize the flexibility of the contact surface. Contact, and intelligent control of adhesion and detachment. The adhesive suction cup is composed of an adhesive suction cup outer pad 1 and an adhesive suction cup inner cavity 2. Both the adhesive suction cup outer pad 1 and the adhesive suction cup inner cavity 2 are made of flexible magnetic response materials. The shape of the pad 1 and the inner cavity 2 of the adhesive suction cup is designed and manufactured to imitate the design of the octopus sucker. The outer pad 1 of the adhesive suction cup and the inner cavity 2 of the adhesive suction cup will receive completely opposite forces under the same magnetic ...

Embodiment 2

[0064] The difference between this embodiment and the first embodiment is that the adhesive suction cup in this embodiment has a thickness of 6mm and a radius of 40mm.

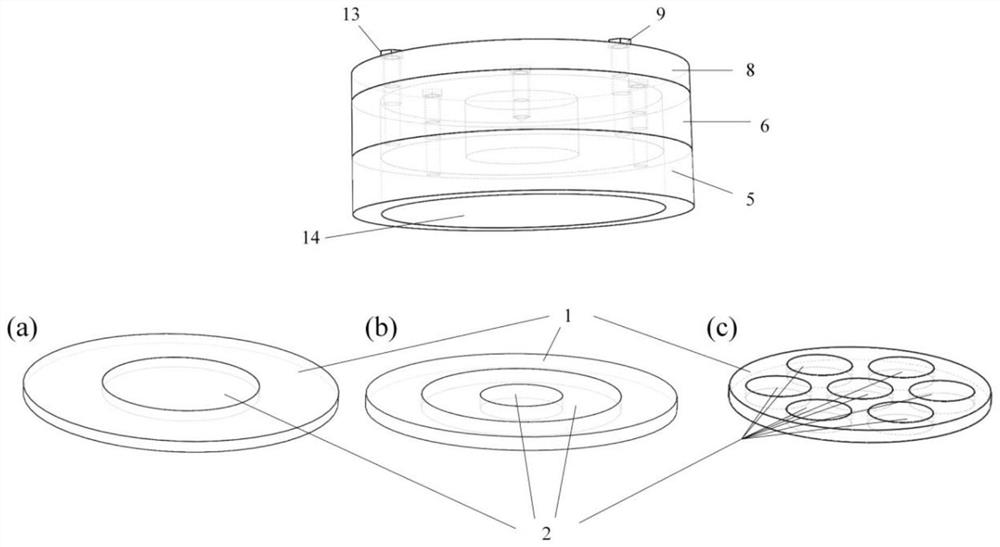

[0065] The octopus-like sucker design scheme of the adhesive suction cup chooses to nest a plurality of adhesive suction cup inner cavities 2 with different deformation effects in the middle of the adhesive suction cup outer pad 1. From the outside to the inside, the negative pressure deformation ability gradually increases: the adhesive suction cup outer pad 1 The outer diameter is 40mm, the inner diameter is 30mm, the inner cavity of the adhesive suction cup is divided into two parts, the innermost part of the inner cavity has the best deformation effect, and the radius is 20mm, and the outer part of the inner cavity has an outer diameter of 30mm and an inner diameter of 20mm, such as figure 2 (b) shown.

[0066] There is a 14mm cylindrical cavity in the middle of the connecting ring 5, which serves as the ...

Embodiment 3

[0072] The difference between this embodiment and the above embodiments is that the thickness of the adhesive suction cup in this embodiment is 8mm, and the radius is 60mm.

[0073] The design scheme of the octopus-like sucker of the adhesive sucker is chosen to distribute 2n+1 inner cavities of the adhesive sucker evenly in the middle of the outer pad of the adhesive sucker and the outer ring. The distance between the sucker lumens is equal, and n is 3: there are 7 sticky sucker lumens 2 with a radius of 18mm in the sticky sucker, one sticky sucker lumen 2 in the center of the middle circle, and the remaining 6 sticky sucker lumens 2 are at a distance of Both the inner chamber 2 of the adhesive suction cup and the outer pad 1 of the adhesive suction cup have an edge of 3mm, and are evenly distributed in it at intervals of 60°. figure 2 (c) shown.

[0074] There is a 15mm cylindrical cavity in the middle of the connecting ring 5, which serves as the deformation domain adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com