Structural wave-absorbing composite material and preparation method thereof

A composite material and wave-absorbing layer technology, applied in the field of wave-absorbing materials, can solve the problems of high density, poor high-temperature thermal stability, and large thickness of coating-type wave-absorbing materials, and achieve excellent wave-absorbing performance and mechanical load-bearing performance, and improve Mechanical properties, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

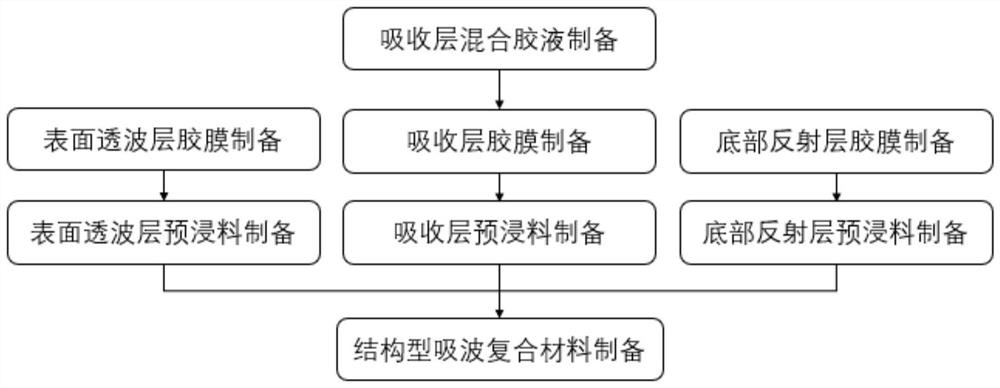

Method used

Image

Examples

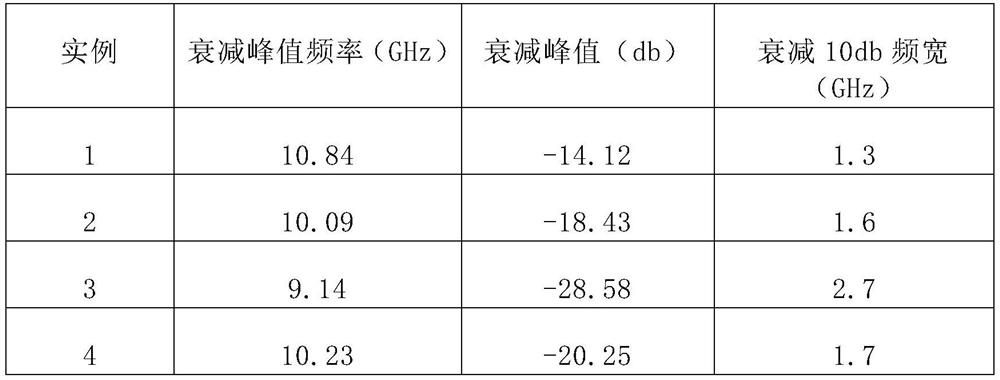

example 1

[0022] A self-made low-viscosity hot-melt epoxy resin is added to a coating machine to prepare an epoxy resin film, and the viscosity of the resin film at 50° C. is lower than 40000 cps. Put the film and aramid fiber into the impregnation machine for continuous hot-press impregnation to prepare the wave-transmissive layer prepreg, the impregnation temperature is 70-90°C, and the impregnation speed is <5m / min. The prepared wave-transparent layer prepreg has a resin content of 50 wt%.

[0023] Put the self-made low-viscosity hot-melt epoxy resin at 60-85°C and add it to the double planetary dispersion mixer. The viscosity of the resin at 60°C is lower than 10000cps; the stirring temperature is the same as the resin hot-melt temperature, stirring for 3-5min, The resin is in a melted homogeneous state. Then add superconducting carbon black in 3-4 times, and stir for 5 minutes after each addition, wherein superconducting carbon black D50 is 7-9um, D90 is 10-15um, and the resistivi...

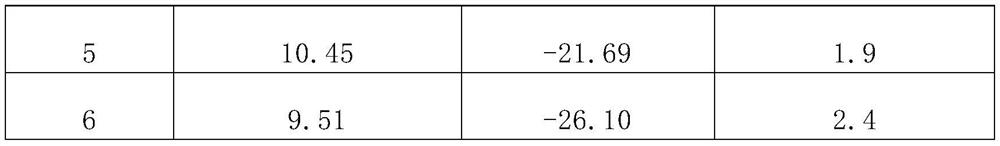

example 2

[0027] The difference from Example 1 is that the wave-transmitting layer fibers are quartz fibers, and the resin content is 45wt%; the added carbon-based absorbent is graphene, D50 is 6-10um, D90 is 10-15um, and the resistivity is 0.05-0.2 Ω m; the mass fraction ratio of each component of the prepreg for the absorbing layer: resin: hybrid fiber: wave absorbing agent is 39:60:1; the hybrid fiber for the prepreg for the absorbing layer is aramid fiber / carbon fiber (carbon fiber accounts for 35wt% ).

example 3

[0029] The difference from Example 1 is that the resin content of the wave-transparent layer is 30wt%; the added carbon-based absorbent is superconducting carbon black and graphene, wherein the superconducting carbon black D50 is 5-10um, D90 is 12-15um, and the resistance The resistivity is 0.25-0.75Ω m, the graphene D50 is 6-10um, the D90 is 10-15um, the resistivity is 0.1-0.3Ω m, the mass ratio of superconducting carbon black to graphene is 3:2; The mass fraction ratio of each component of impregnation resin: hybrid fiber: wave absorbing agent is 46:50:4; the resin content of the reflection layer is 35wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com