Low-friction low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A polyolefin cable material and low-friction technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as poor flexibility, achieve the effects of reducing water absorption, improving frost resistance, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

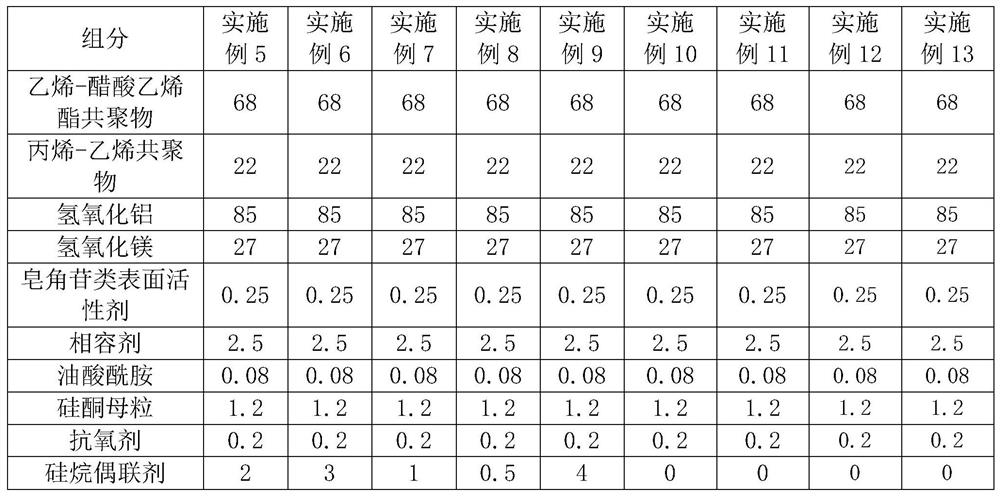

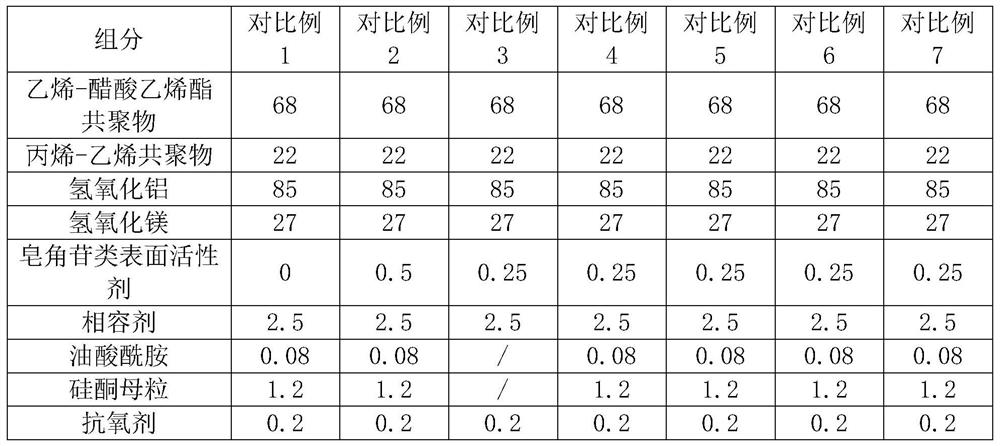

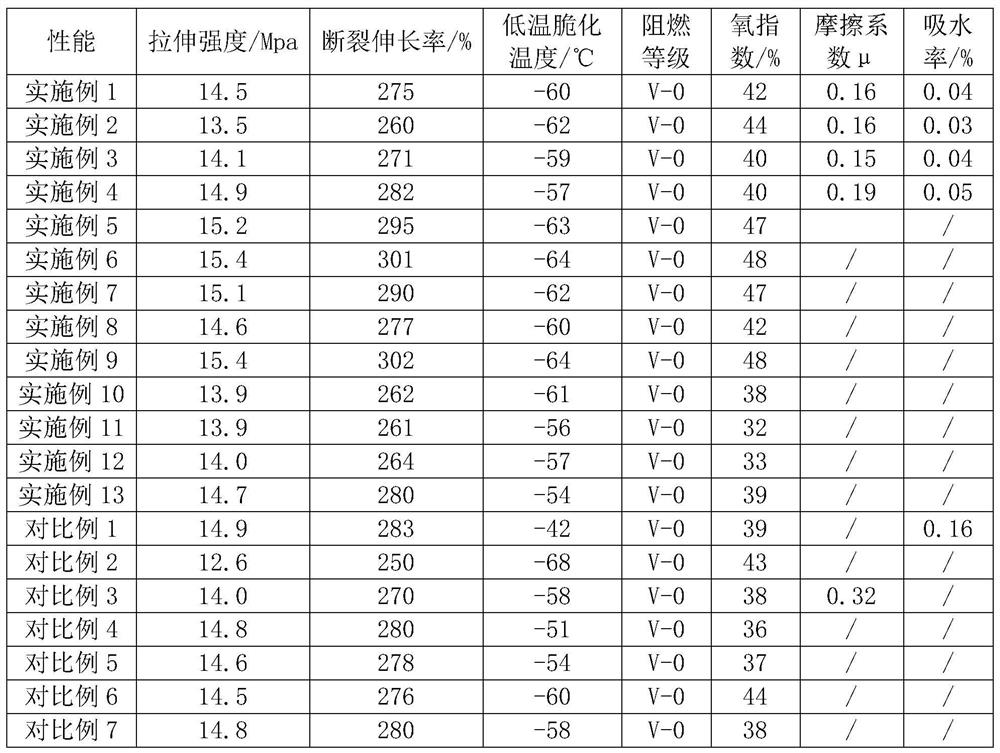

Examples

Embodiment 1

[0055] Example 1: A low-friction, low-smoke, halogen-free, flame-retardant polyolefin cable material, the components of its raw materials and their corresponding weights are shown in Table 1, wherein the particle size of magnesium hydroxide and aluminum hydroxide is 1- 5 μm, and prepared by the following steps:

[0056] Step 1: Put the ethylene-vinyl acetate copolymer into a heating and stirring tank and heat it to a molten state, set the heating temperature to 78°C, and spray the aqueous solution of hydrophobic surfactant while stirring the ethylene-vinyl acetate copolymer in the molten state , the concentration of the aqueous solution of the hydrophobic surfactant is 2.5%, until it is evenly stirred to obtain the first mixture;

[0057] Step 2, put aluminum hydroxide, magnesium hydroxide, oleic acid amide, silicone masterbatch, compatibilizer and antioxidant into a high-speed mixer and stir to mix evenly to obtain a second mixture;

[0058] Step 3, adding the second mixture...

Embodiment 2

[0060] Example 2: A low-friction, low-smoke, halogen-free, flame-retardant polyolefin cable material. The difference from Example 1 is that the components of the raw materials and their corresponding weights are shown in Table 1, and are prepared by the following steps get:

[0061] Step 1: Put the ethylene-vinyl acetate copolymer into a heating and stirring tank and heat it to a molten state, set the heating temperature to 80°C, and spray the aqueous solution of hydrophobic surfactant while stirring the ethylene-vinyl acetate copolymer in the molten state , the concentration of the hydrophobic surfactant aqueous solution is 2%, until the mixing is uniform, and the first mixture is obtained;

[0062] Step 2, put aluminum hydroxide, magnesium hydroxide, oleic acid amide, silicone masterbatch, compatibilizer and antioxidant into a high-speed mixer and stir to mix evenly to obtain a second mixture;

[0063] Step 3, adding the second mixture into a banbury mixer for high-pressure...

Embodiment 3

[0065] Example 3: A low-friction, low-smoke, halogen-free, flame-retardant polyolefin cable material. The difference from Example 1 is that the components of the raw materials and their corresponding weights are shown in Table 1, and are prepared by the following steps get:

[0066] Step 1, put the ethylene-vinyl acetate copolymer into a heating and stirring tank and heat it to a molten state, set the heating temperature to 77°C, and spray a hydrophobic surfactant aqueous solution on the molten ethylene-vinyl acetate copolymer while stirring , the concentration of the aqueous solution of the hydrophobic surfactant is 3%, until the mixing is uniform, and the first mixture is obtained;

[0067] Step 2, put aluminum hydroxide, magnesium hydroxide, oleic acid amide, silicone masterbatch, compatibilizer and antioxidant into a high-speed mixer and stir to mix evenly to obtain a second mixture;

[0068] Step 3, adding the second mixture into a banbury mixer for high-pressure banbury...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com