A kind of liquid metal thermal paste and preparation method thereof

A technology of liquid metal and heat conduction paste, which is applied in the field of heat conduction paste, can solve the problems of high fluidity of gallium alloy, poor performance of gallium alloy, and influence on service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

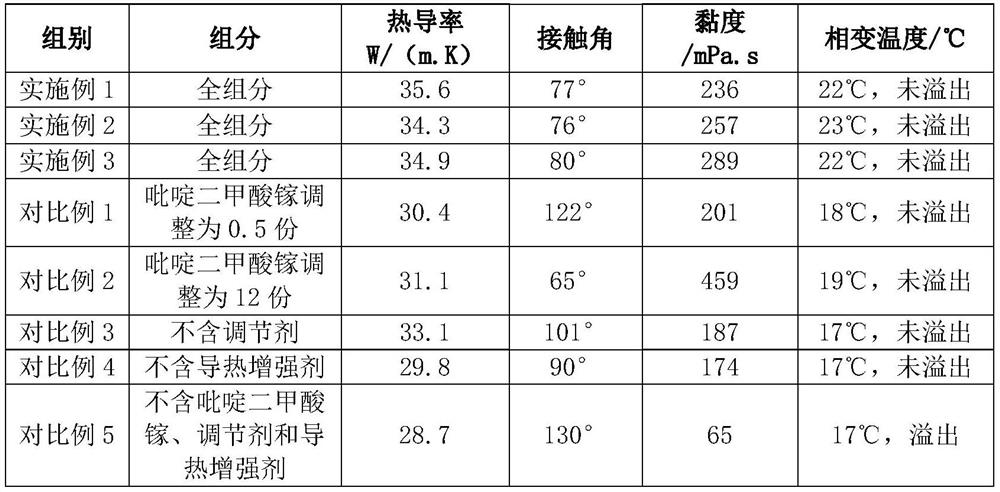

Examples

Embodiment 1

[0021] A liquid metal thermal conductive paste, composed of components of weight sharing:

[0022] The gallium indium tin alloy is 70 parts, 6 parts of pyridate, 8 parts of the thermal reinforcing copper powder and 2 parts of the regulator.

[0023] The method of preparing the liquid metal thermant paste described in this example, comprising the steps of:

[0024] The copper powder was placed in a vacuum drying tank in a vacuum drying tank at an 80 ° C for 5 h, and copper powder was added to the molten liquid metal gallium indium tin alloy, gallium pyridate and metallium trichloride, stirring the mixture in a vacuum environment. The temperature was kept above 25 ° C, and the rotation speed was 150 rpm at stirring, the stirring time was 8 min, stirred well, and the liquid metal heat conduction paste was obtained.

Embodiment 2

[0026] A liquid metal thermal conductive paste, composed of components of weight sharing:

[0027] The gallium indium tin alloy is 80 parts, 2 parts of pyridate, 5 parts of the thermal reinforcing copper powder and 3 parts of the regulator.

[0028] The method of preparing the liquid metal thermant paste described in this example, comprising the steps of:

[0029] The copper powder was placed in a vacuum drying tank at a vacuum tank at a vacuum tank at a vacuum drying tank, and copper powder was added to the molten liquid metal gallium indium tin alloy, gallium pyridate and metallium trichloride, stirring the mixture in a vacuum environment. The temperature was kept above 25 ° C, and the rotational speed was 200 rpm at stirring, the stirring time was 5 min, stirred well, and the liquid metal heat transfer paste was obtained.

Embodiment 3

[0031] A liquid metal thermal conductive paste, composed of components of weight sharing:

[0032] The gallium indium tin alloy is 60 parts, 8 parts of pyridic acid, 10 parts of the thermal reinforcing copper powder and 1 part of the regulator.

[0033] The method of preparing the liquid metal thermant paste described in this example, comprising the steps of:

[0034] The copper powder was placed in a vacuum drying tank at an 80 ° C vacuum drying tank for 6 h, and copper powder was added to the molten liquid metal gallium indium tin alloy, gallium pyridate, gallium tartride, and mixed mixture in a vacuum environment. The temperature was kept above 25 ° C, and the rotation speed was 100 rpm at the time of stirring, the stirring time was 10 min, stirred well, and the liquid metal heat conduction paste was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com