Preparation method of low-cost functional polymer type fracturing fluid

A functional, fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effect of good shear resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

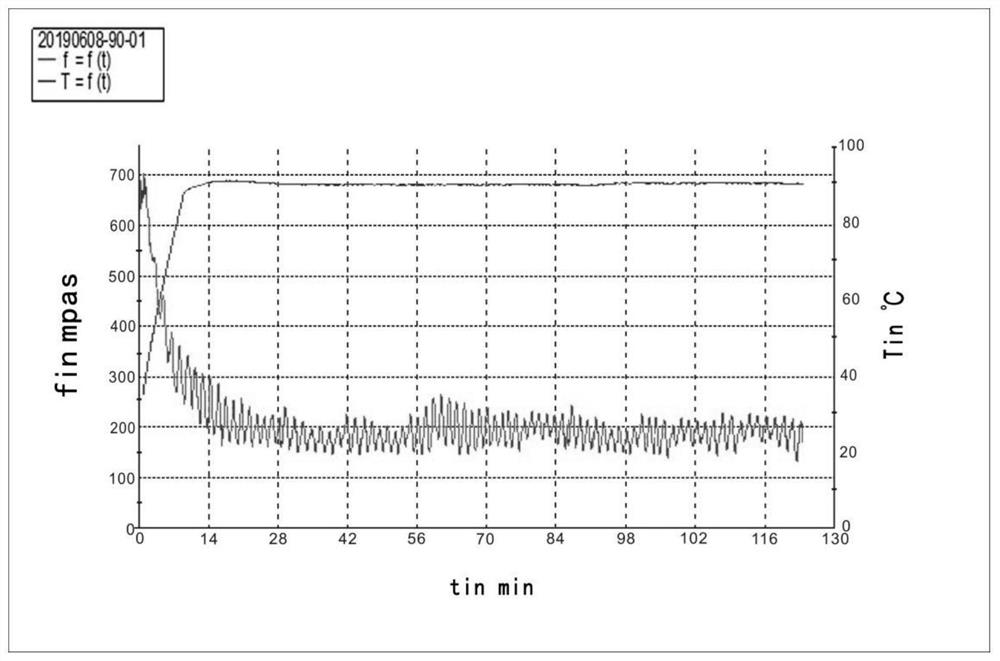

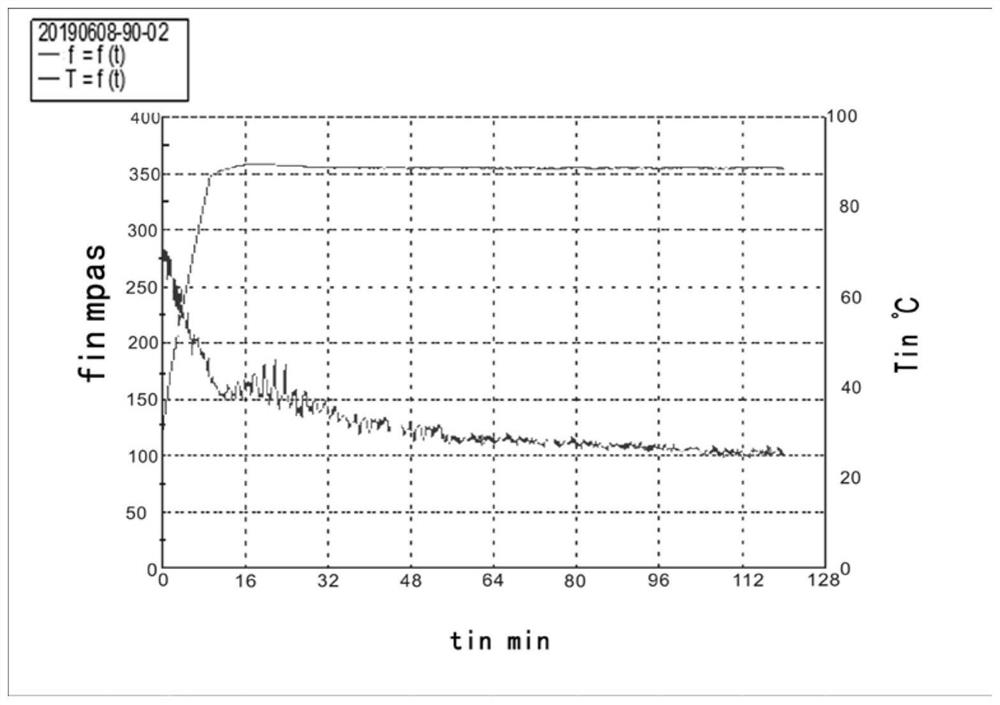

Image

Examples

specific Embodiment 1

[0031] (1) Add 350kg of acrylamide monomer, 36kg of maltodextrin, 62kg of 2-acrylamide-2-methylpropanesulfonic acid, and 36kg of N-vinyl-2-pyrrolidone into the water containing the reaction medium. 449kg, span60 23kg, tween80 25kg reaction kettle, react at 45°C for 2h, add initiator potassium persulfate 0.75kg, nitrogen protection, violent polymerization reaction occurs, and react for 2h after stabilization; multi-component copolymer colloid is obtained.

[0032] (2) The copolymer colloid is sheared and granulated, dried and pulverized to obtain a low-cost functional polymer fracturing fluid---thickener.

[0033] Cross-linking agent specific embodiment 1

[0034] (1) Weigh 136kg of zirconium oxychloride, 60kg of isoamyl alcohol, and polyols (glycerol, 120kg of mannitol, and 60kg of mannitol) and add them to a reaction kettle that has weighed 289kg of water; heat to 35°C for 1 hour;

[0035] (2) Add 35kg of rhamnolipid, heat at 50°C for reflux reaction for 1h;

[0036] (3) Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap