Controlled circulating water shrimp culture system and working method

A technology of circulating water and control system, which is applied to the adjustment method of biological treatment, chemical instruments and methods, and fish farming, etc. It can solve the problem that shrimp shells cannot be discharged in time, shorten the time of film formation, and accelerate the maturation of biofilm in biofilters, etc. problems, to achieve the effect of reducing the risk of infectious diseases, shortening the time of membrane formation, and reducing the pressure of biological filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

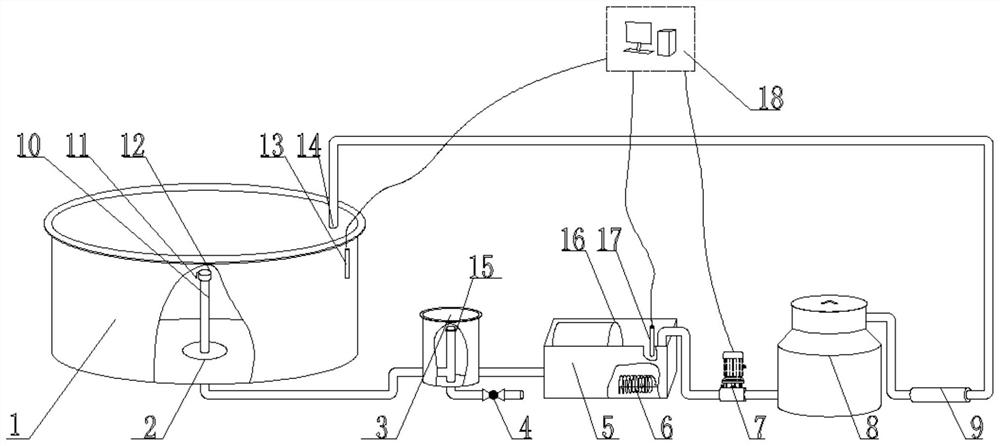

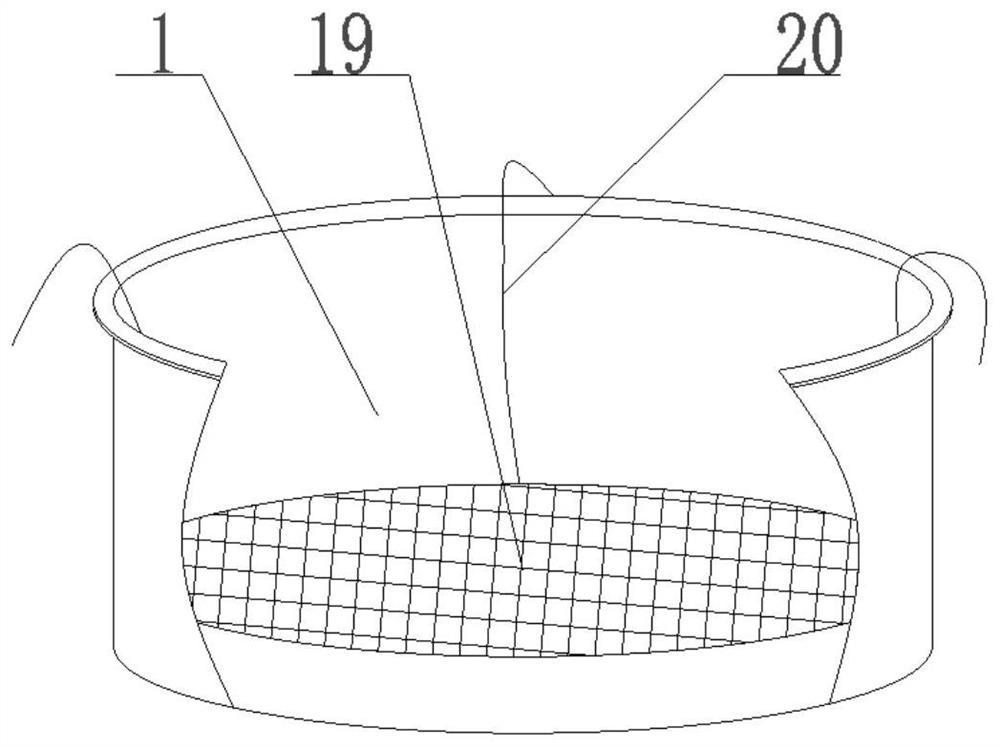

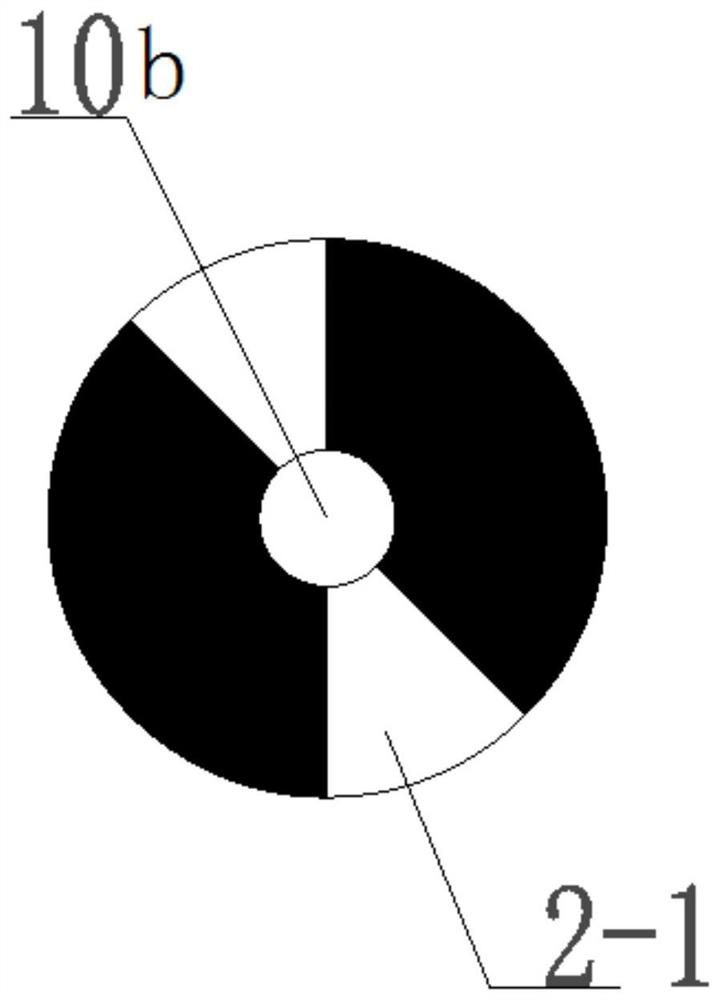

[0040] A controlled circulating water shrimp farming system is mainly composed of a culture pond, a water treatment system, a temperature control system, a central control system, water quality monitoring equipment and a sterilization device, wherein the culture pond contains double-layer drainage pipes, double-layer circular Bottom row device, rotating structure, water inlet pipe and habitat platform; water treatment system mainly includes water level maintainer, micro filter, regulating tank, moving bed biological filter and ultraviolet sterilization device; central control system consists of intelligent camera, industrial computer and electric control The water quality monitoring equipment is composed of ammonia nitrogen, nitrite nitrogen water quality probes and display panels, of which the ammonia nitrogen and nitrite nitrogen water quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com