A kind of preparation method of protective clothing for spraying pesticide

A technology for protective clothing and pesticides, which is applied in the field of preparation of protective clothing for spraying pesticides, can solve the problems of pesticide dripping on the skin, pollution, contact, etc., and achieves the effect of broad market application prospects and good moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

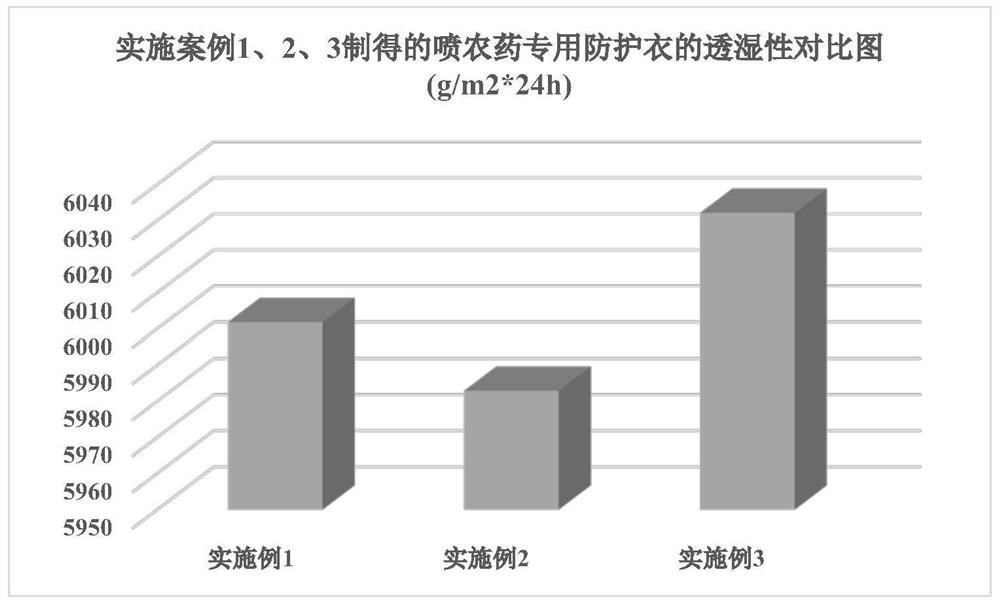

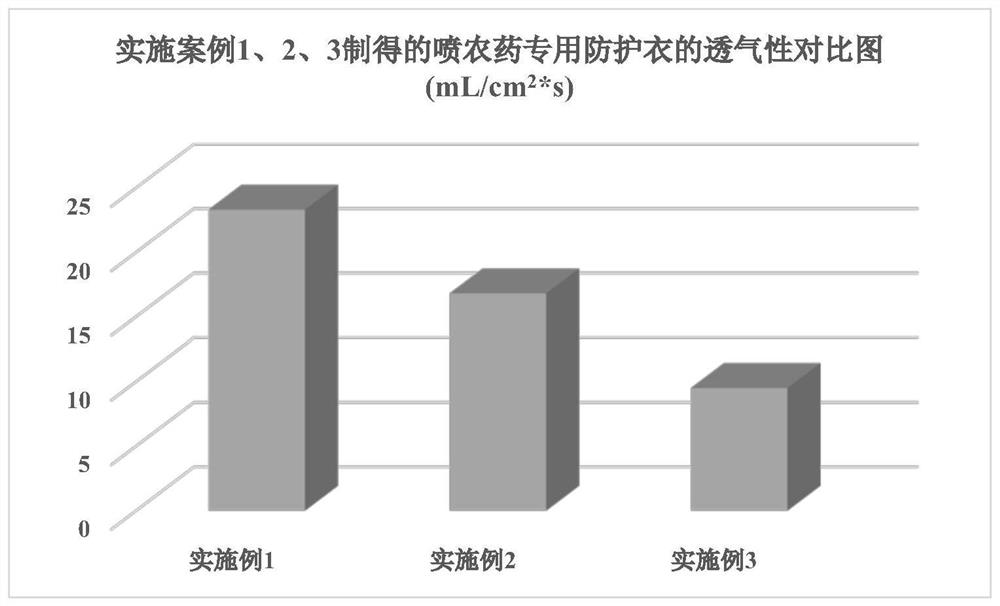

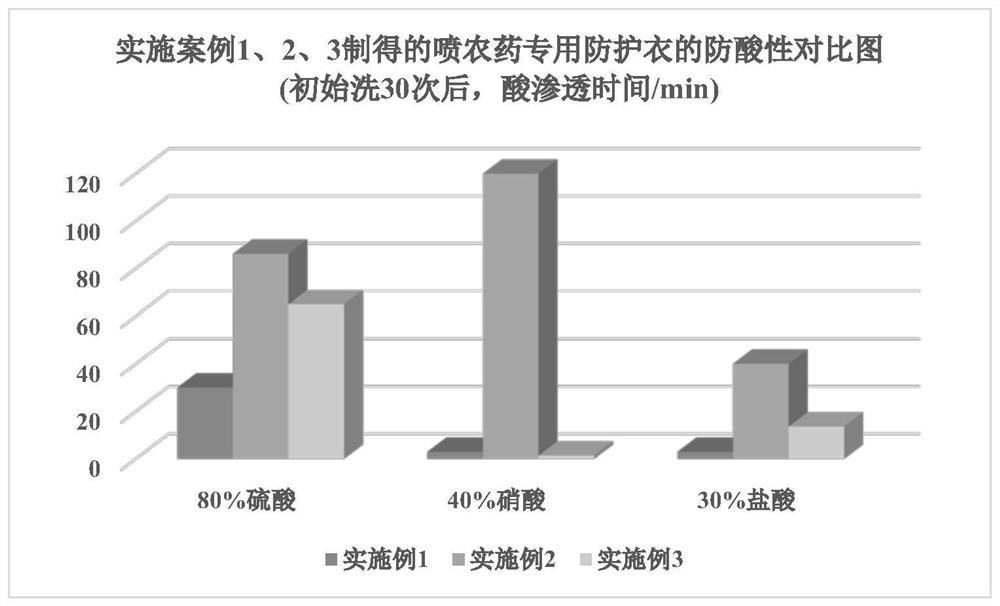

[0020] Mix 3 mL of 8 mg / mL graphene oxide with 4.5 mg of multi-walled carbon nanotubes to form a graphene oxide-multi-walled carbon nanotubes composite, and dry it in a freeze dryer at -40°C for 12 hours; The dried composite is subjected to self-propagating combustion reduction to form a composite of reduced graphene oxide-multi-walled carbon nanotubes; the polypropylene (PP) homopolymer resin and copolymer resin with a mass ratio of 3:7 are mixed, and then Add the composite of reduced graphene oxide-multi-walled carbon nanotubes and flame retardant QB–PN4 to it, and then blow it out through a film blowing machine at an extrusion temperature of 185°C and a speed of 5m / min to form a barrier film; the formed layer 1. The barrier film and the skeleton layer are heat-pressed by a high-pressure heat press machine with a hot-melt adhesive film at a temperature of 125° C. for 5 s to obtain a fabric, and the fabric is processed into a raincoat, and a raincoat is obtained after packagin...

Embodiment 2

[0022] Mix 3 mL of 8 mg / mL graphene oxide with 4.5 mg of multi-walled carbon nanotubes to form a graphene oxide-multi-walled carbon nanotubes composite, and dry it in a freeze dryer at -40°C for 12 hours; The dried composite is subjected to self-propagating combustion reduction to form a composite of reduced graphene oxide-multi-walled carbon nanotubes; the polypropylene (PP) homopolymer resin and copolymer resin with a mass ratio of 2:8 are mixed, and then Add the composite of reduced graphene oxide-multi-walled carbon nanotubes and flame retardant QB–PN4 to it, and then blow it out through a film blowing machine at an extrusion temperature of 185°C and a speed of 5m / min to form a barrier film; the formed layer 1. The barrier film and the skeleton layer are heat-pressed by a high-pressure heat press machine with a hot-melt adhesive film at a temperature of 125° C. for 5 s to obtain a fabric, and the fabric is processed into a raincoat, and a raincoat is obtained after packagin...

Embodiment 3

[0024] Mix 3 mL of 8 mg / mL graphene oxide with 4.5 mg of multi-walled carbon nanotubes to form a graphene oxide-multi-walled carbon nanotubes composite, and dry it in a freeze dryer at -40°C for 12 hours; The dried composite is subjected to self-propagating combustion reduction to form a composite of reduced graphene oxide-multi-walled carbon nanotubes; the polypropylene (PP) homopolymer resin and copolymer resin with a mass ratio of 1:9 are mixed, and then Add the composite of reduced graphene oxide-multi-walled carbon nanotubes and flame retardant QB–PN4 to it, and then blow it out through a film blowing machine at an extrusion temperature of 185°C and a speed of 5m / min to form a barrier film; the formed layer 1. The barrier film and the skeleton layer are heat-pressed by a high-pressure heat press machine with a hot-melt adhesive film at a temperature of 125° C. for 5 s to obtain a fabric, and the fabric is processed into a raincoat, and a raincoat is obtained after packagin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com