Cabin temperature detector and manufacturing method thereof

A technology of a temperature detector and a manufacturing method, which is applied to the temperature measurement of moving fluids, thermometers, and parts of thermometers, etc., can solve the problems of insufficient optimization of the production process, low product quality, and low production efficiency of the cabin temperature detector, and achieve Improve quality and production efficiency, improve assembly efficiency, and have good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

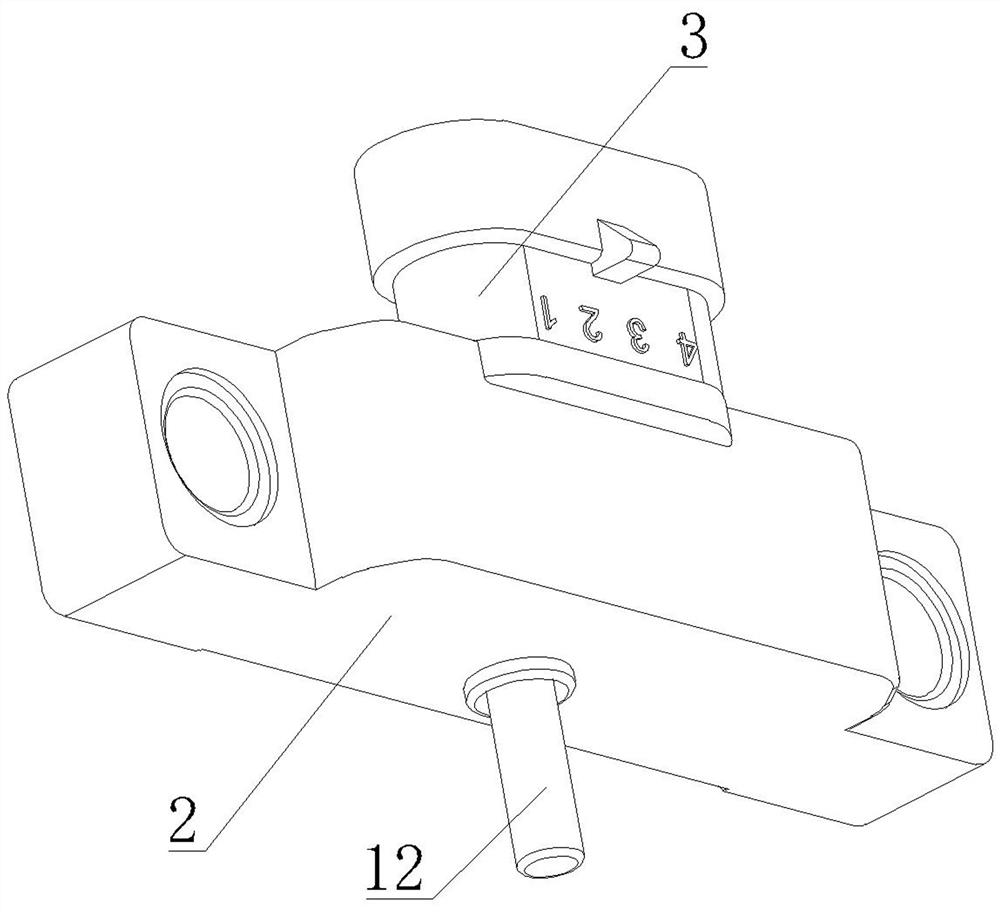

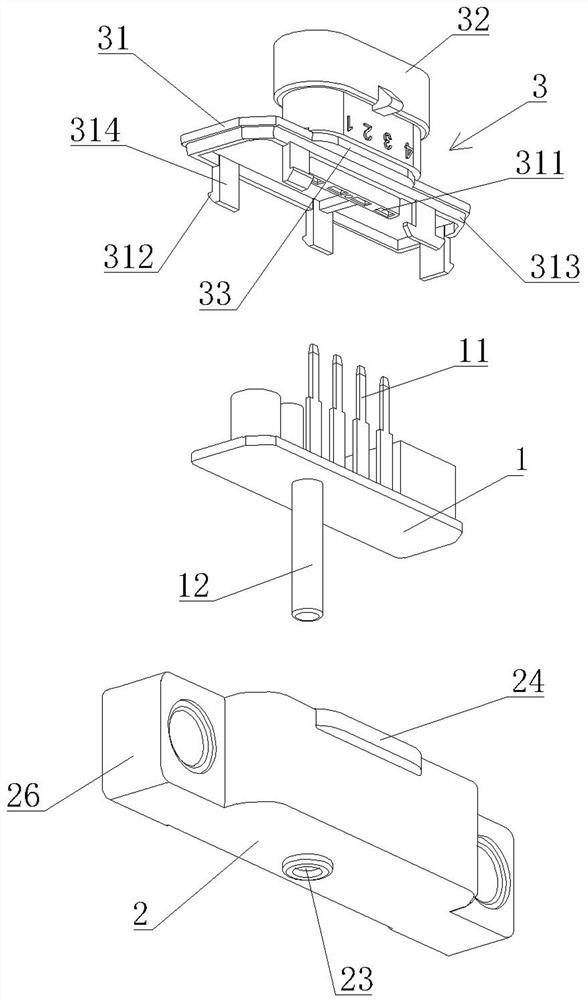

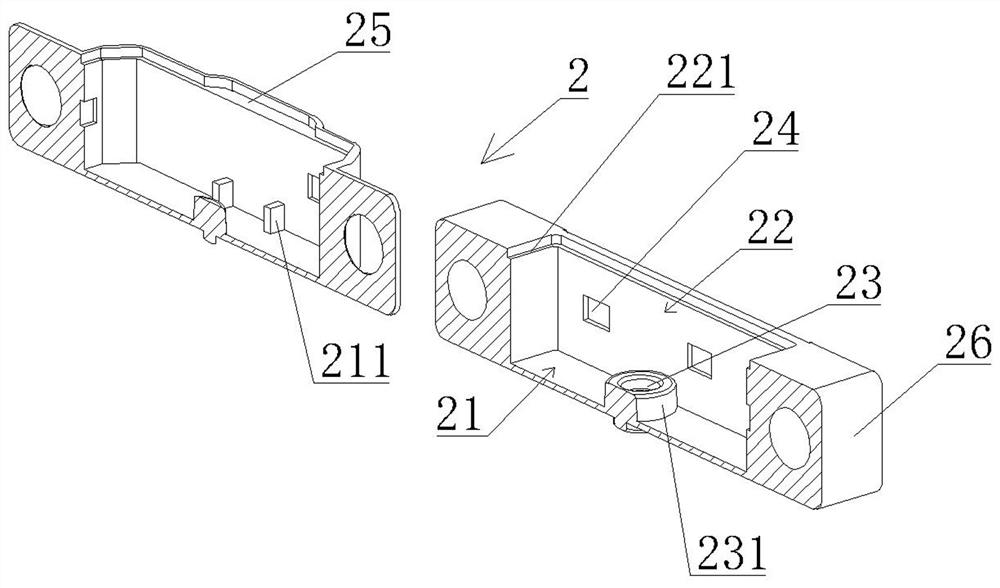

[0044] A cabin temperature detector, see Figure 1 to Figure 3 .

[0045] The engine room temperature detector provided by the embodiment of the present invention includes a circuit board 1, which is a double-sided circuit board, electronic components can be arranged on both sides of the upper and lower sides, and a temperature detection circuit is arranged on the circuit board 1, and the temperature detection circuit is electrically connected There are four connecting terminals 11 arranged on the upper surface of the circuit board 1, and these four connecting terminals are input signal lines, output signal lines, control unit ground lines and instrument panel ground lines respectively.

[0046] A temperature probe 12 is provided on the lower surface of the circuit board 1. The temperature detection circuit includes a temperature sensing element. The temperature probe 12 is located at one end of the circuit board 1 and contacts the temperature sensing element, so that the temp...

Embodiment 2

[0060] A kind of manufacture method of cabin temperature detector, please refer to Figure 4 .

[0061] The manufacturing method of the cabin temperature detector of this embodiment comprises the following steps:

[0062] Step S100, making a temperature detection circuit board, a lower casing and an upper cover.

[0063] In this step, the circuit board, lower case and upper cover are manufactured according to the principle, structure and shape of the circuit board, lower case and upper cover in Embodiment 1. Dividing the entire engine room temperature detector into these three parts is convenient for later assembly, which is conducive to simplifying the assembly process and improving production efficiency.

[0064] Step S200, loading the circuit board into the lower casing, and allowing the temperature probe to pass through the perforation.

[0065] In this step, the bottom surface of the circuit board is supported on the support column and two support platforms on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com