Freeze-dried kumquat slices and preparation method thereof

A technology for freeze-dried tablets and a drying method, which is applied in the field of kumquat freeze-dried tablets and its preparation, can solve the problems that kumquat rough processed products cannot meet the fashion demands of consumers, poor product flavor and quality, backward processing technology, etc. Natural health benefits, good flavor and quality, and the effect of reducing the bitterness of kumquats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

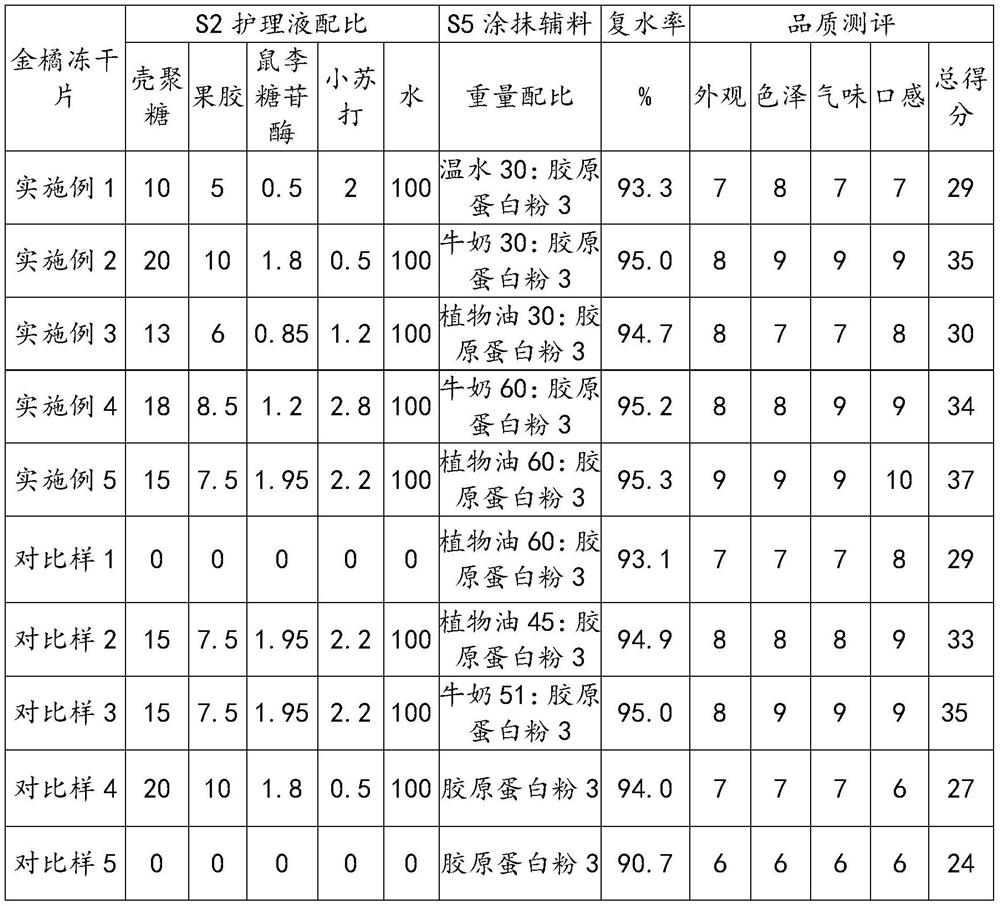

Examples

Embodiment 1

[0041] Prepare kumquat freeze-dried slices as follows:

[0042] S1: Take 1000 parts of fresh kumquat fruit, remove the stalks, wash, dry in a cool place, store at 2°C for 24 hours, take it out, and get refrigerated kumquat fruit;

[0043] S2: Take the refrigerated kumquat fruit and open the bottom and top of the kumquat fruit respectively, and evenly spray the care solution on the outer surface of the peel, dry the surface moisture, and set aside;

[0044] Wherein, the care solution includes the following material composition in parts by weight: 10 parts of chitosan, 5 parts of pectin, 0.5 parts of rhamnosidase, 2 parts of baking soda, and 100 parts of water.

[0045] S3: Cut the treated kumquat fruit into thin slices of about 2 mm, spread them on trays, and the thickness of the trays should not exceed 10 mm;

[0046] S4: After the temperature of the freeze-drying warehouse is lowered to -30°C, put the trays containing kumquat slices into the tray for pre-freezing;

[0047] ...

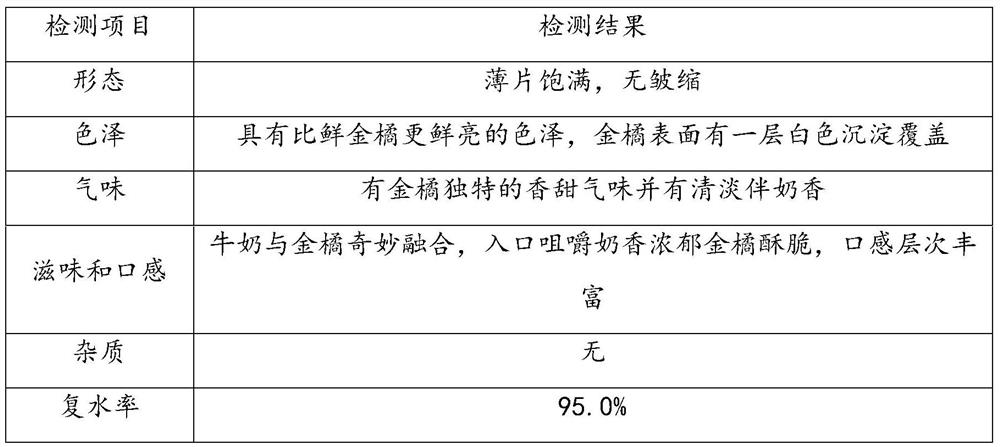

Embodiment 2

[0059] Prepare freeze-dried kumquat slices as follows:

[0060] S1: Take 1000 parts of fresh kumquat fruit, remove the stalks, wash, dry in a cool place, store at 3°C for 40 hours, take it out, and get refrigerated kumquat fruit;

[0061] S2: Take the refrigerated kumquat fruit and open the bottom and top of the kumquat fruit respectively, and evenly spray the care solution on the outer surface of the peel, dry the surface moisture, and set aside;

[0062] Wherein, the nursing solution includes the following material composition in weight ratio: 20 parts of chitosan, 10 parts of pectin, 1.8 parts of rhamnosidase, 0.5 parts of baking soda, and 100 parts of water.

[0063] S3: Cut the treated fresh kumquat into thin slices of about 2 mm, spread them on trays, and the thickness of the trays should not exceed 10 mm;

[0064] S4: After the temperature of the freeze-drying warehouse is lowered to -30°C, put the trays containing kumquat slices into the tray for pre-freezing;

[0...

Embodiment 3

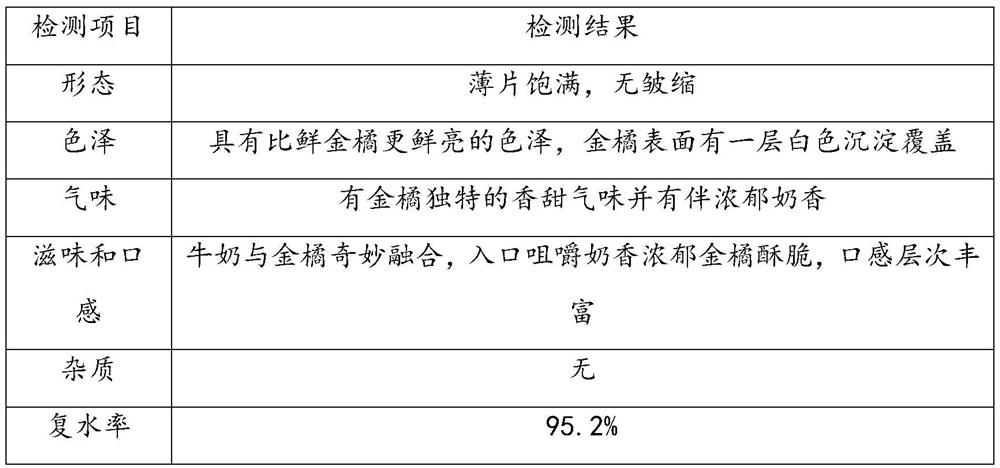

[0077] Prepare kumquat freeze-dried slices as follows:

[0078] S1: Take 1000 parts of fresh kumquat fruit, remove the stalks, wash, dry in a cool place, store at 3°C for 24 hours, take it out, and obtain refrigerated kumquat fruit;

[0079] S2: Take the refrigerated kumquat fruit and open the bottom and top of the kumquat fruit respectively, and evenly spray the care solution on the outer surface of the peel, dry the surface moisture, and set aside;

[0080] Wherein, the care solution includes the following material composition in parts by weight: 13 parts of chitosan, 6 parts of pectin, 0.85 parts of rhamnosidase, 1.2 parts of baking soda, and 100 parts of water.

[0081] S3: Cut the treated kumquat fruit into thin slices of about 2 mm, spread them on trays, and the thickness of the trays should not exceed 10 mm;

[0082] S4: After the temperature of the freeze-drying warehouse is lowered to -30°C, put the trays containing kumquat slices into the tray for pre-freezing;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com