Pipeline argon arc spot welding process parameter quantitative control device, system and method

A technology of process parameter and quantitative control, applied in arc welding equipment, electrode support device, device supporting electrode clamp, etc., can solve the problems of blocking the inner hole of the conduit, the welding seam forming, the welding forming incomplete penetration, and the size out of tolerance, etc. Achieve the effect of reducing the space volume, relaxing the direction of the pipeline, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

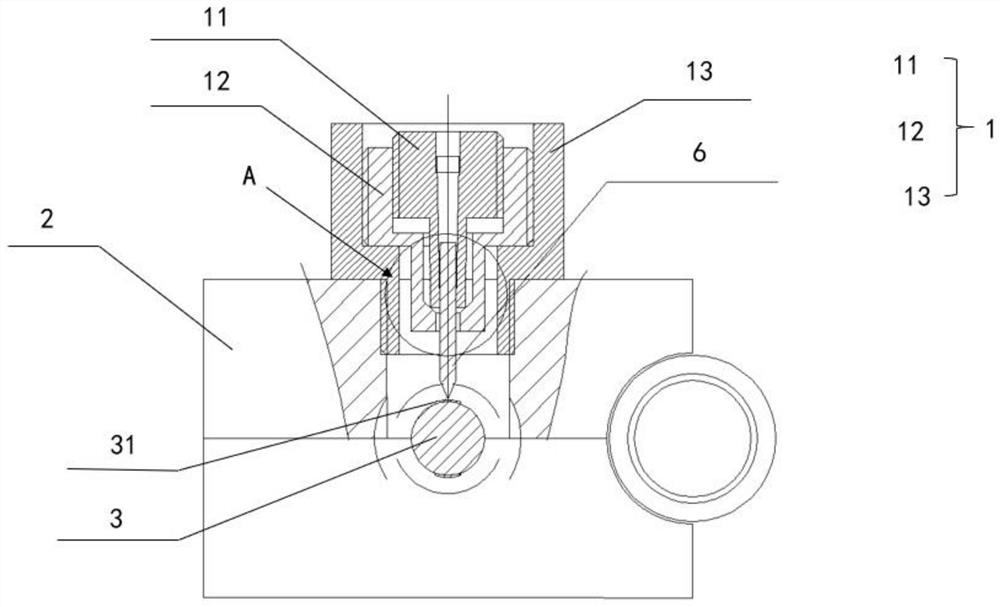

[0046] Such as Figure 1-10 As shown, the application of the present invention provides a quantitative control device for pipeline argon arc spot welding process parameters, including a welding torch assembly 1 and a clamping device 2, and welding is realized through the installation and deployment of the welding torch assembly 1 and the clamping device 2 The adjustment of the height between the tungsten electrode 6 and the welding seam is used to improve the spot welding accuracy, and the details are as follows:

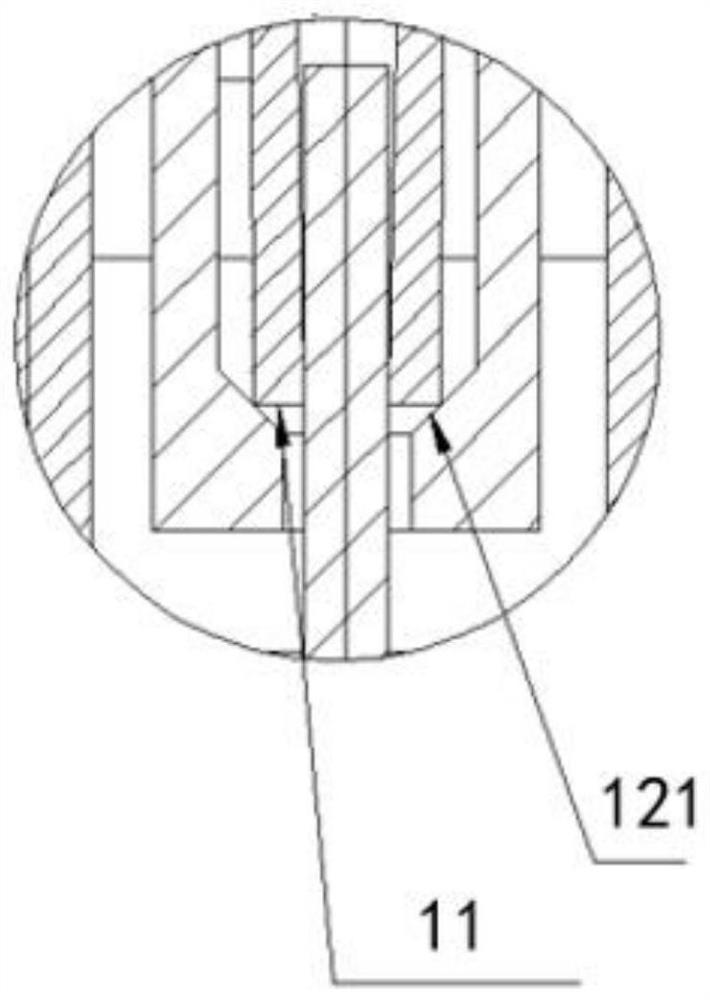

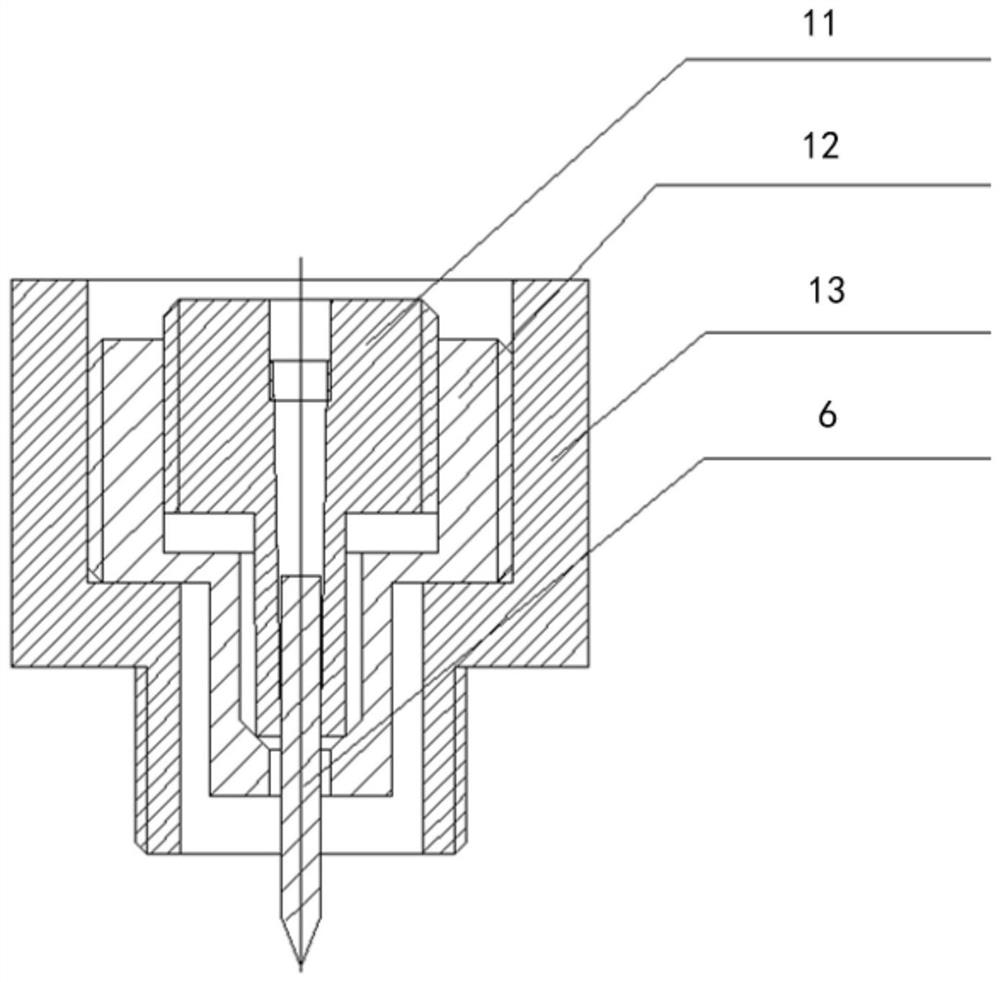

[0047]The welding torch assembly 1 comprises a tungsten pole clamping inner core 11, a tungsten pole clamping overcoat 12 and a base 13, wherein the base 13 is preferably a ceramic base, and its tungsten pole clamping inner core 11, a tungsten pole clamping overcoat 12 and a base 13 are all boss-type open cylinder structures, but the inner diameters of the three are different, and the connection mode of the three is socket, that is, the inner core 11 of the tungsten...

Embodiment 2

[0053] Such as Figure 1-10 As shown, this embodiment 2 is formed on the basis of embodiment 1, and the precise positioning of the height of the tungsten pole is mainly realized through the corresponding tooling, specifically:

[0054] The precise positioning of the height of the tungsten electrode is realized by adding a height positioning tool 3, the height positioning tool 3 is the same as the pipe diameter of the pipe to be welded, and the surface of the height positioning tool 3 is equipped with a height adjustment sheet 31, and the height positioning tool 3 is clamped on the In the clamping part 21, the base 13 with the tungsten pole clamping inner core 11 and the tungsten pole clamping overcoat 12 fixed is installed in the junction part 22. There is a certain distance between the surfaces, and the extension line of the central axis of the tungsten pole clamping inner core 11 passes through the height adjusting piece 31 . When height positioning the tungsten pole 6, put...

Embodiment 3

[0057] Such as Figure 1-10 As shown, this embodiment 3 is formed on the basis of embodiment 2, and a pipeline argon arc spot welding process parameter quantitative control system formed by using the pipeline argon arc spot welding process parameter quantification control device described in embodiment 2 , also includes an automatic argon arc welding control device 4, an arc welding electrical adapter 5 and a tungsten electrode 6, the tungsten electrode clamping jacket 12 is connected with the automatic argon arc welding control device 4 through the arc welding electrical adapter 5, and the tungsten electrode 6 is clamped on the tungsten pole clamping inner core 11, and the tip of the tungsten pole 6 extends beyond the welding torch assembly 1, specifically, extends beyond the peripheral surface of the base 13, and is located on the weld seam of the pipe to be welded .

[0058] Its pipeline argon arc spot welding process parameter quantification control system also includes w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com