Antistatic silicone release film

A silicone and antistatic technology, applied in conductive coatings, film/sheet release liners, film/sheet adhesives, etc., can solve problems such as high production costs and quality problems, and achieve stable release characteristics , the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

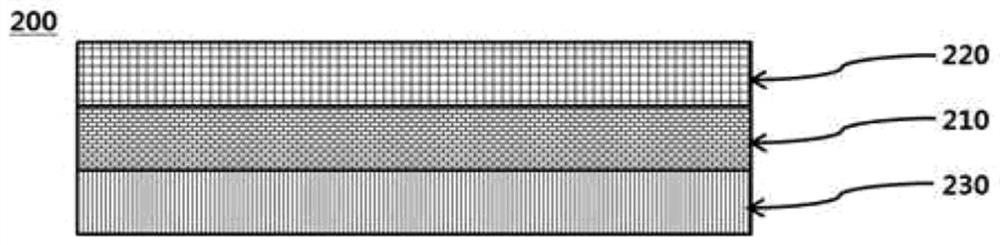

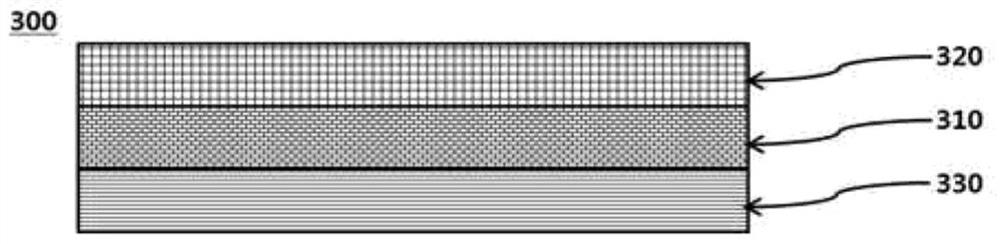

Image

Examples

Embodiment 1

[0104] In order to form an antistatic silicone release layer on one surface of a corona-treated polyester base film (Excell-50 μm, manufactured by Toray Advanced Materials Korea Inc.), based on 100 parts by weight of alkenyl poly Siloxane (manufactured by Dow Corning), 3 parts by weight of hydropolysiloxane (manufactured by Dow Corning), 2.5 parts by weight of conductive polymer resin (containing 0.5% by weight of poly(3,4-ethylene dioxythiophene) and 0.8% by weight of polystyrenesulfonic acid (molecular weight Mn=150000), and an aqueous dispersion with an average particle diameter of 50 nm), 10 parts by weight of an epoxy-based binder compound (manufactured by Esprix Technologies ), 50 ppm of chelated platinum catalyst (manufactured by DowCorning), and 0.2 parts by weight of ionic surfactant (dioctyl sulfosuccinic acid sodium salt) were mixed in water to produce an antistatic silicone release composition .

[0105] The produced antistatic silicone release composition was dil...

Embodiment 2

[0107] An antistatic silicone release film was produced in the same manner as in Example 1, except that 10 parts by weight of a conductive polymer resin was added based on 100 parts by weight of alkenylpolysiloxane.

Embodiment 3

[0109] An antistatic silicone release film was produced in the same manner as in Example 1, except that 2 parts by weight of a conductive polymer resin was added based on 100 parts by weight of alkenylpolysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com