Boat bottom cleaning robot

A technology for cleaning robots and ship bottoms, which is applied to ship cleaning devices, hulls, motor vehicles, etc. It can solve the problems of low cleaning efficiency, increased hull resistance, and long cleaning time, achieving low cleaning costs, comprehensive cleaning, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

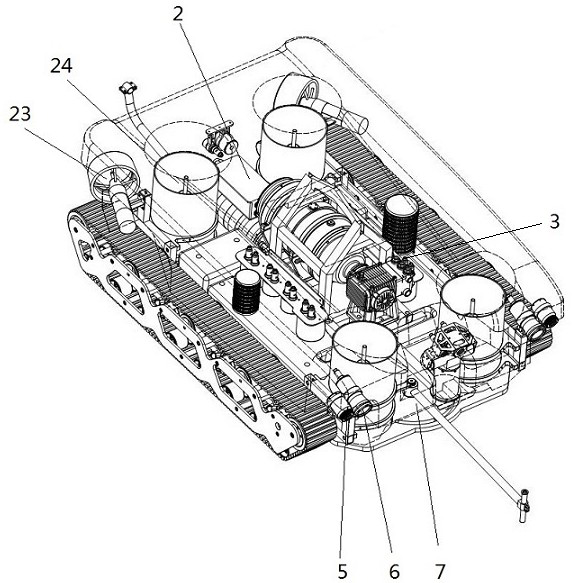

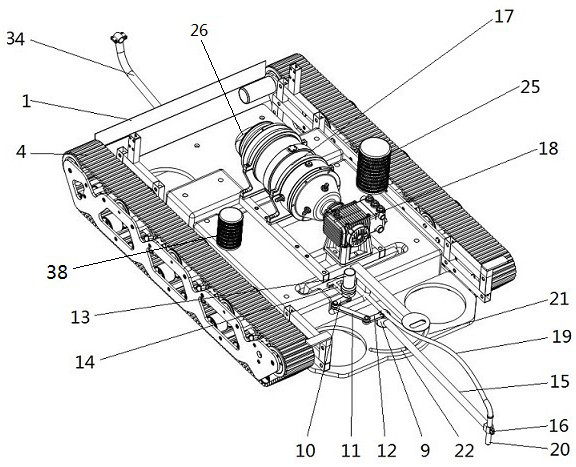

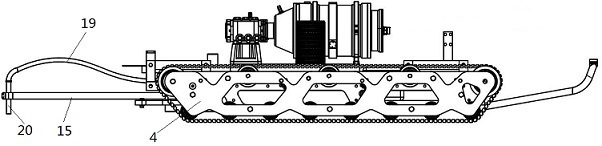

[0024] A ship bottom cleaning robot, comprising a frame 1, the frame 1 is provided with an electrical cabin 2, a traveling mechanism 4 and an image scanning device 5, the electrical cabin 2 is provided with a control system, and the control system communicates with the The water control box is connected, and it is characterized in that: the frame 1 is provided with a cleaning driving mechanism 3 and a nozzle driving mechanism 7, and the cleaning driving mechanism 3 includes a driving assembly, a water inlet pipe, a water outlet pipe 19 and a cavitation nozzle 20, Described driving assembly comprises plunger pump 18 and the underwater motor 17 of driving plunger pump 18, described underwater motor 17 and plunger pump 18 are respectively fixed on the frame 1, and described underwater motor 17 is connected with control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com