A kind of hyperbranched polyetheramine environmental protection shale inhibitor and its preparation method and water-based drilling fluid

A technology of hyperbranched polyetheramine and shale inhibitor, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of low degree of branching, and achieve simple synthesis, safe drilling, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 10.4095g of 2,2′-oxybis(ethylamine), dissolve it in 41.638g of tetrahydrofuran, and transfer it to a 250mL round bottom flask, then weigh 9.7158g of diallylamine, dissolve it in 38.86 Add the tetrahydrofuran solution of diallylamine dropwise to the round bottom flask at a rate of 2 d / s at 25°C under magnetic stirring conditions, raise the temperature to 60°C, and blow nitrogen. Reflux reaction for 24h.

[0025] (2) After the reaction is over, remove tetrahydrofuran by rotary evaporation at a temperature of 45°C to obtain a viscous light yellow liquid, add 50 mL of acetone while stirring at 25°C to wash the viscous light yellow liquid 4 times , centrifuged, separated, and vacuum-dried at 50°C to obtain a white solid substance, which is the hyperbranched polyetheramine environmental protection shale inhibitor A1.

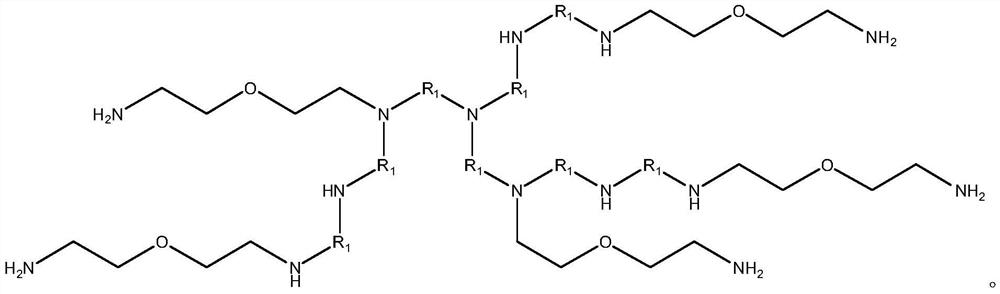

[0026]

[0027] Among them, R1 is -CH 2 CH 2 CH 2 —.

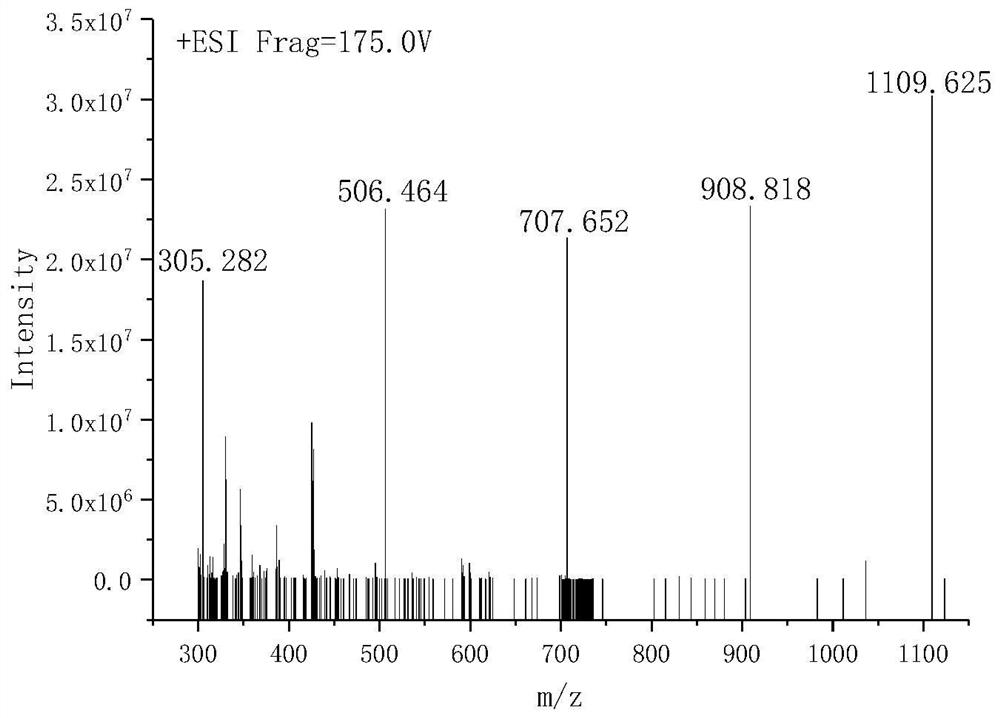

[0028] The molecular weight of the above-mentioned product A1 is detected, and the fin...

Embodiment 2

[0030] (1) Weigh 13.2204g of aminopropyl ether, dissolve it in 52.88g of ethanol, and transfer it to a 250mL round bottom flask, then weigh 9.7158g of diallylamine, dissolve it in 38.86g of ethanol, at 25°C 1. Under the condition of magnetic stirring, the ethanol solution of diallylamine was dropped into the round bottom flask at a rate of 2d / s, the temperature was raised to 80°C, and nitrogen was blown. Reflux reaction for 16h.

[0031] (2) After the reaction is over, remove tetrahydrofuran by rotary evaporation at a temperature of 50°C to obtain a viscous light yellow liquid, add acetone 50mL to wash the viscous light yellow liquid 4 times while stirring at 25°C, and centrifuge , separated, and vacuum-dried at 60° C. to obtain a white solid substance, which is the hyperbranched polyetheramine environmental protection shale inhibitor A2.

[0032]

[0033] Among them, R 1 for—CH 2 CH 2 CH 2 —.

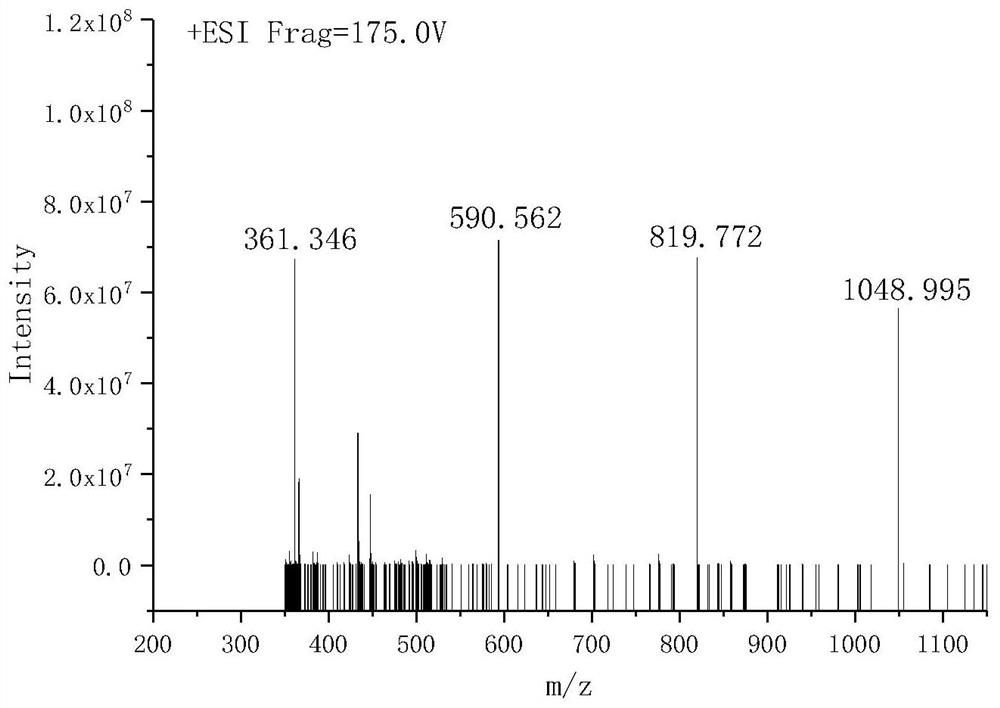

[0034] The molecular weight of above-mentioned product A2 is detected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com