Thermal-type based oily sewage pipeline cleaning device

A technology for sewage pipes and cleaning devices, which is applied to water supply devices, cleaning sewer pipes, water/sewage treatment, etc. It can solve the problems of narrowing the inner diameter of pipes, difficulty in cleaning, and adhesion of particles, so as to accelerate dissolution, improve service life, and not easily Corroded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

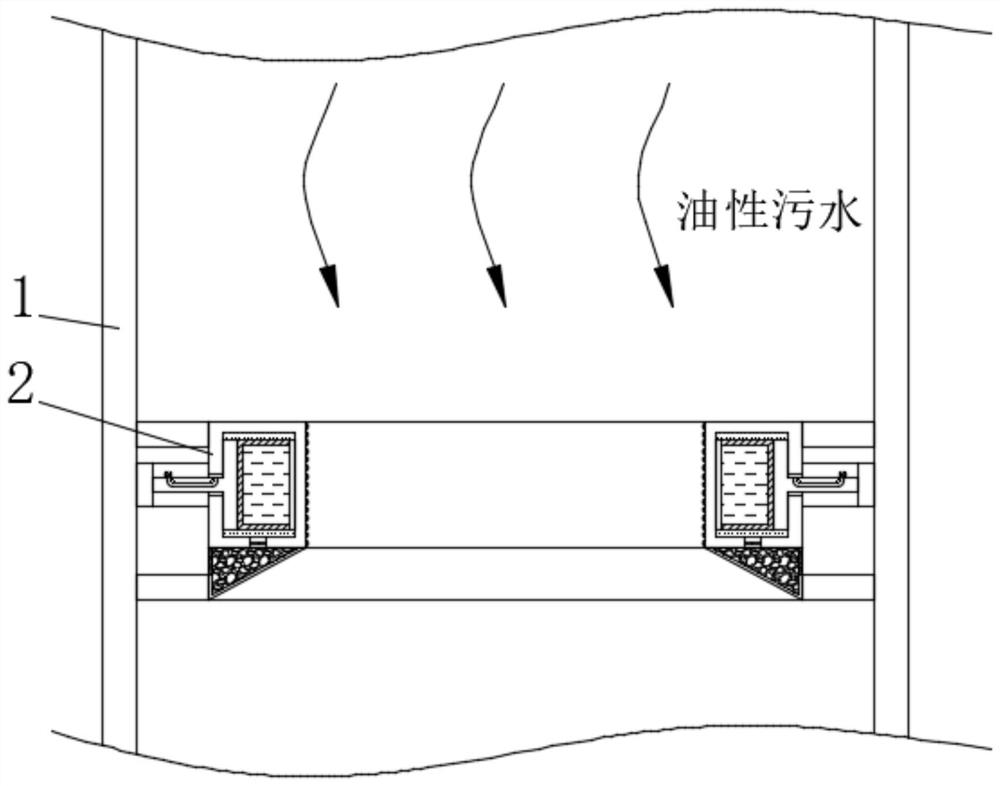

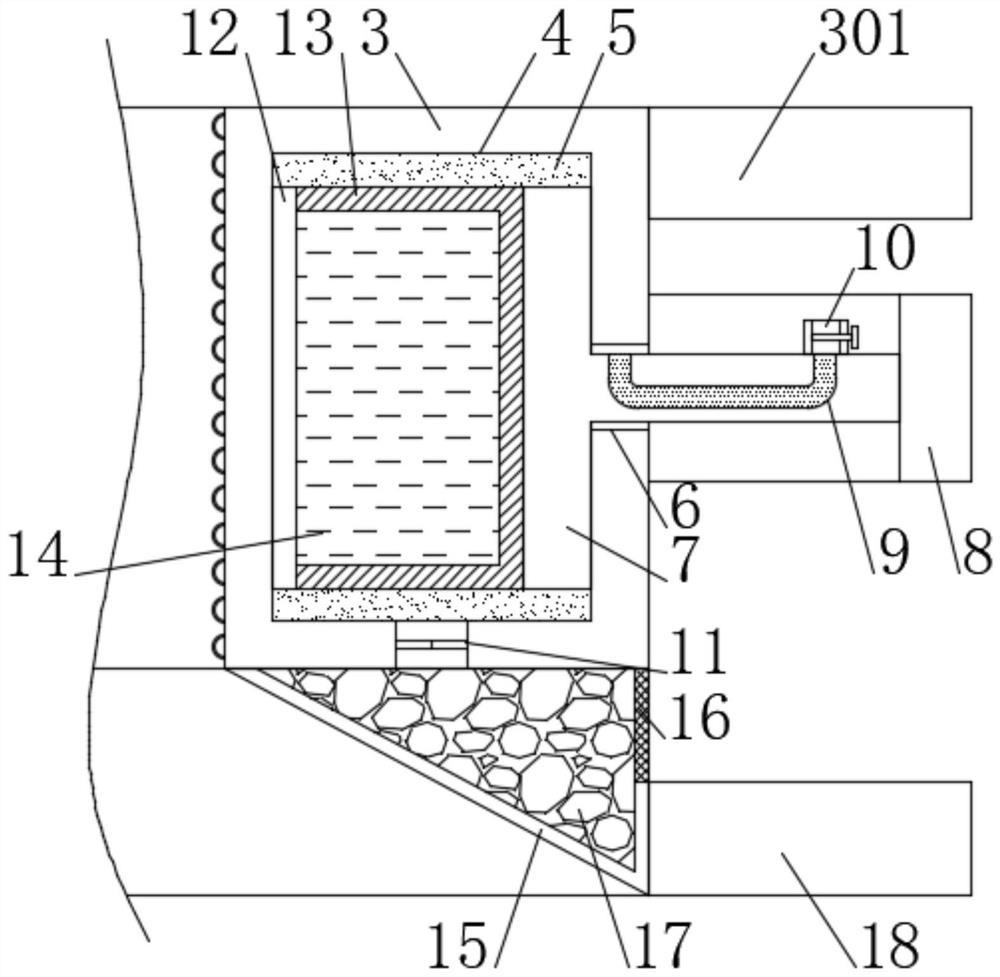

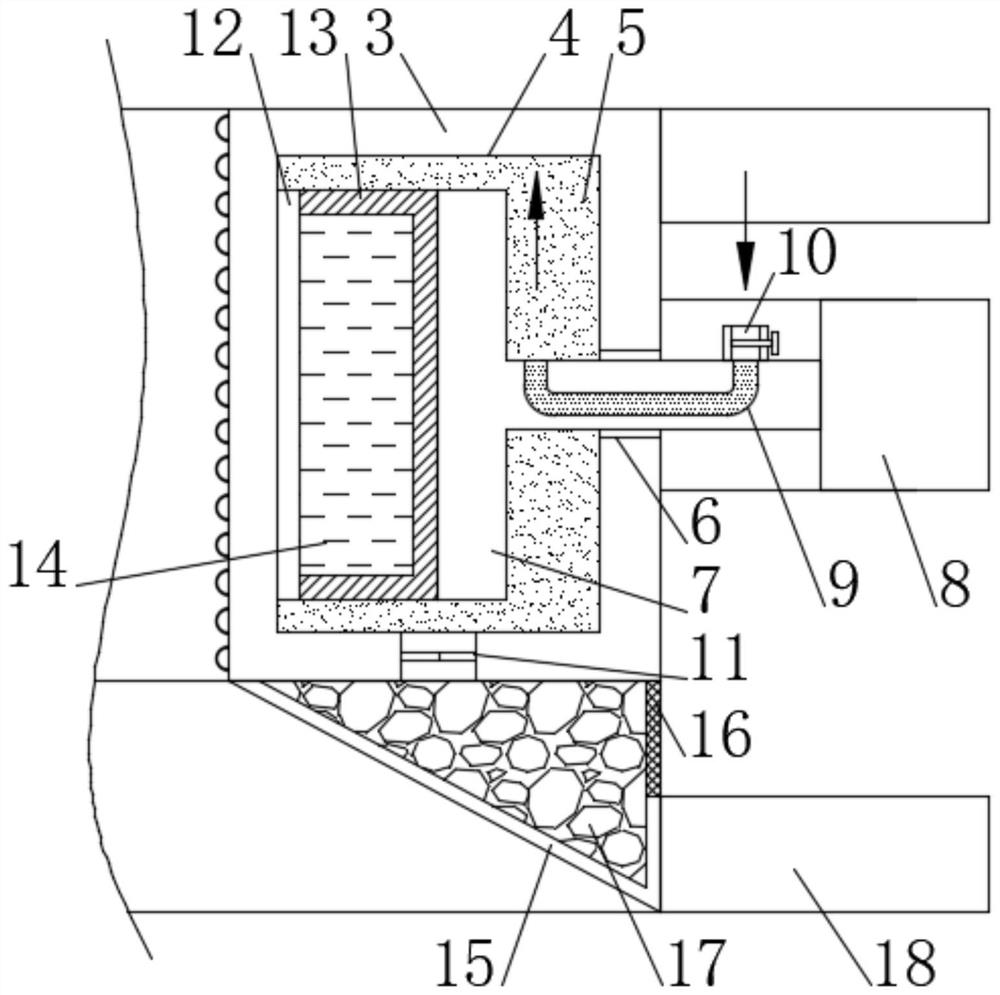

[0043] see Figure 1-5 , a device for cleaning oily sewage pipelines based on heat, comprising a drain pipe 1, a heat wash ring 2 is arranged in the drain pipe 1, the heat wash ring 2 includes an inner storage ring 3, and the inner storage ring 3 is excavated There is a storage cavity 4, which is filled with calcium oxide powder 5, and the outer end of the inner storage ring 3 is dug with a plurality of evenly distributed through holes 6 connected with the storage cavity 4, and T-shaped supports are inserted in the through holes 6 Block 7, the outer end of the T-shaped support block 7 is fixedly connected with a water-expandable water-stop ring 8 located outside the inner storage ring 3, the upper end of the T-shaped support block 7 is dug with a U-shaped conduit 9, and the upper end of the T-shaped support block 7 is fixedly connected with a The one-way valve 10 located on the outside of the water-expandable water-stop ring 8, the bottom end of the storage chamber 4 is dug wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com