Intelligent monitoring method for state of hollow drill grinding wheel

A technology of intelligent monitoring and hollow drilling, applied in nuclear methods, measuring devices, processing detection response signals, etc., can solve problems such as difficulty in determining the empirical parameters of support vector machines, and achieve the effect of improving the level of machine tool processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

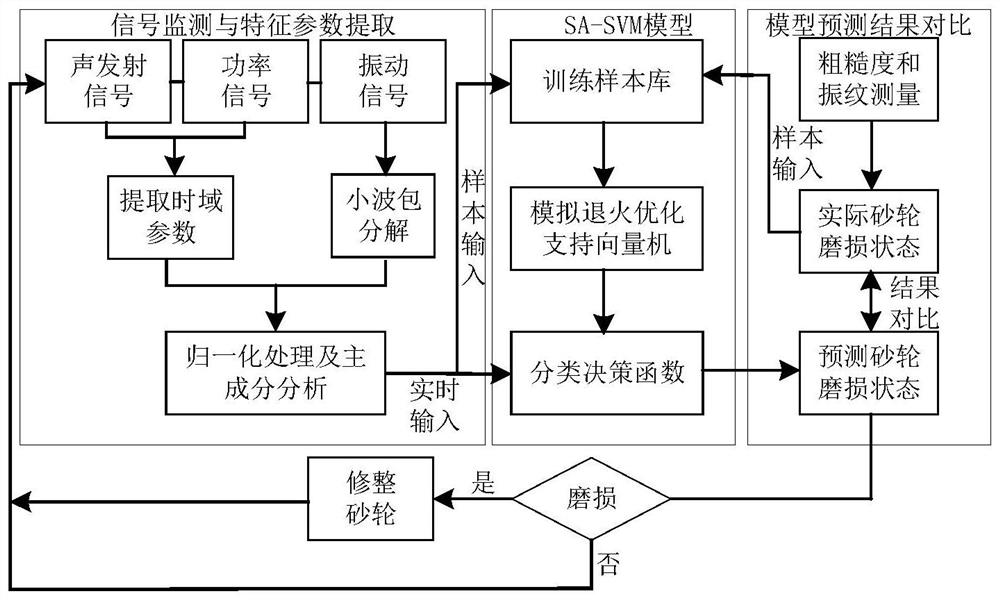

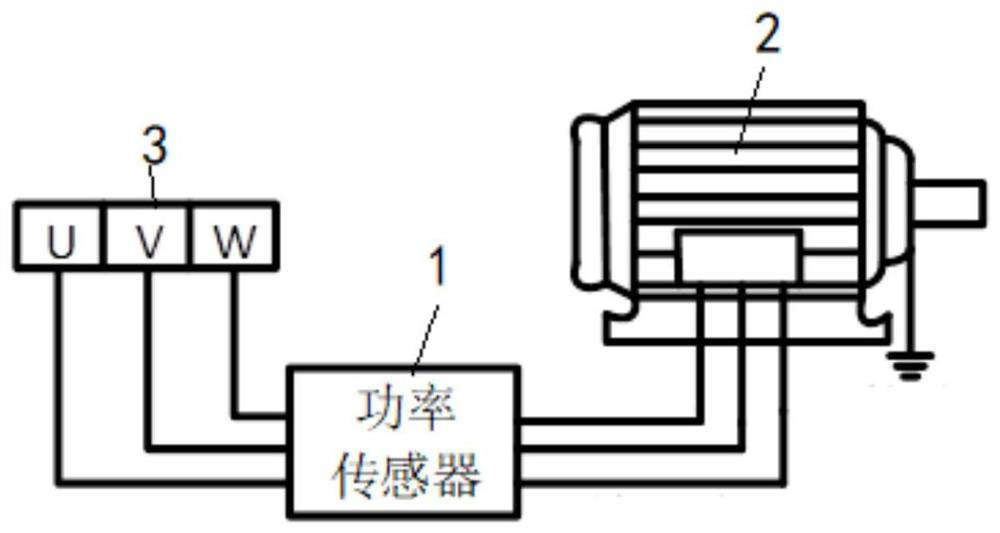

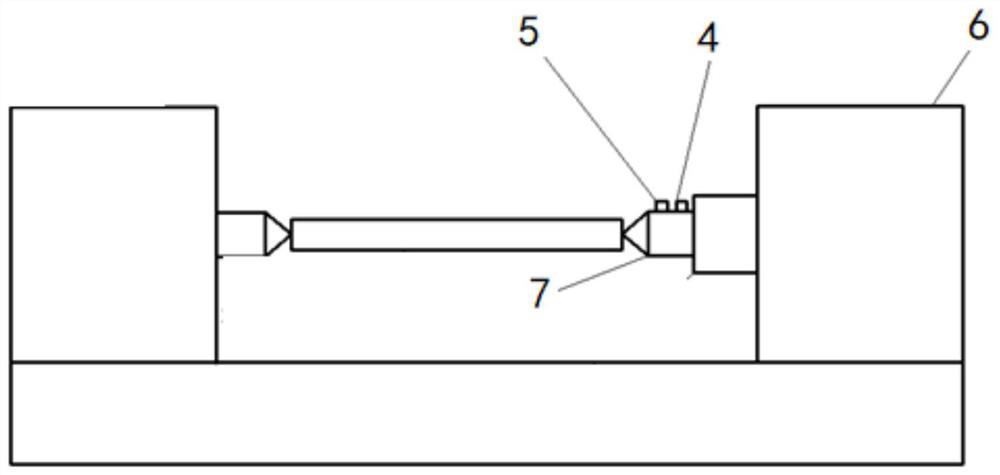

[0038]An intelligent monitoring method for the grinding wheel state of hollow drills. The grinding wheel wear state monitoring system adopted is mainly divided into three parts: signal monitoring and characteristic parameter extraction, SA-SVM model and model prediction results. The first part monitors the acoustic emission signal, power signal and vibration signal in the grinding process, and extracts the time-domain parameters of the acoustic emission signal and power signal and the high-frequency characteristic information of the vibration signal as characteristic parameters, and then normalizes these characteristic parameters Normalize and extract the principal components as the input samples of the SA-SVM model. In the second part, the simulated annealing algorithm is used to optimize the selection of support vector machine parameters, and the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com