Gating tube material, gating tube unit and manufacturing method thereof

A technology of gate tube and material layer, applied in the field of micro-nano electronics, can solve the problem of large turn-on voltage, and achieve the effects of small turn-on voltage, high driving force, and low leakage conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

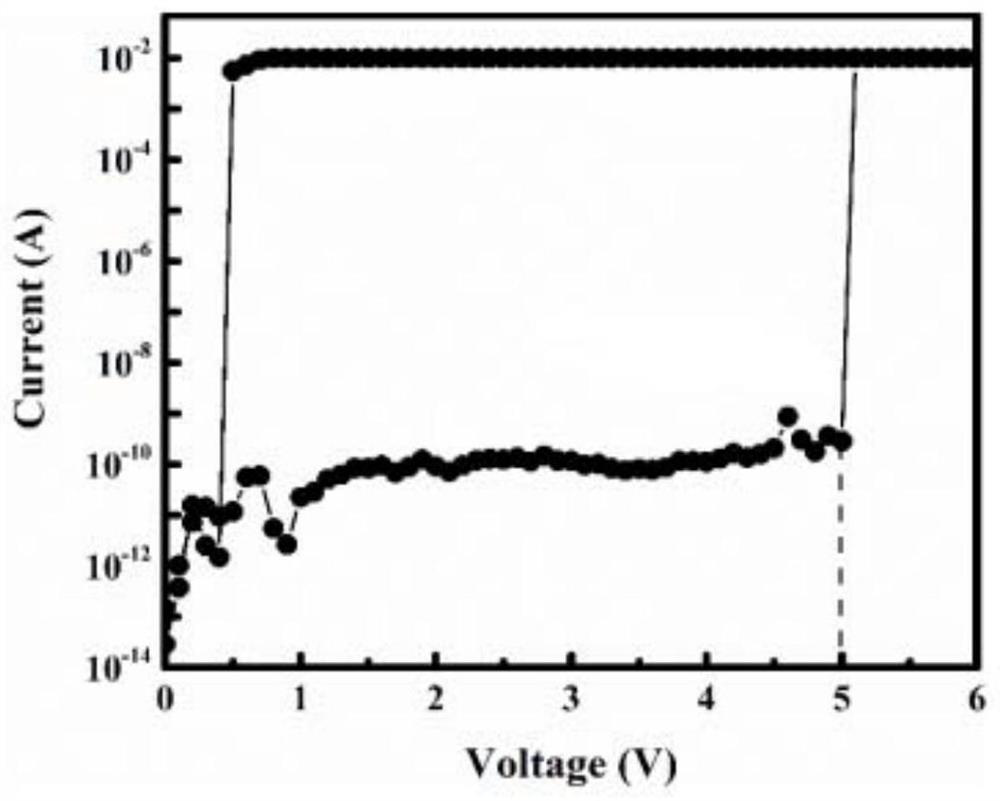

[0053] Such as figure 2 as shown, figure 2 The voltage-current curve of the gating tube unit that is the germanium sulfide (GeS) material preparation in the prior art; The gating tube material layer 1 that the thickness that uses material germanium sulfide (GeS) to obtain is 20 nanometers, and the second electrode 3 is the diameter The first electrode 2 is an aluminum electrode, and a 10 nanometer thick titanium nitride (TiN) transition layer is provided between the first electrode 2 and the material layer 1 of the gate tube.

[0054] Such as figure 2 As shown, when the voltage applied to the gate unit is less than 5V, the gate unit is in the off state, and the leakage current is less than 10 -10 A; When the voltage applied to the gate unit exceeds the threshold voltage, the gate unit is instantly opened, and the current through the gate unit increases sharply to 10 -2 A: When the voltage applied to the gating tube unit is removed (that is, the voltage is 0.5V), the gati...

Embodiment 2

[0063] The through tube material provided by this application combines the GeS target with the As 2 Te 3 The target is obtained by co-sputtering and co-sputtering;

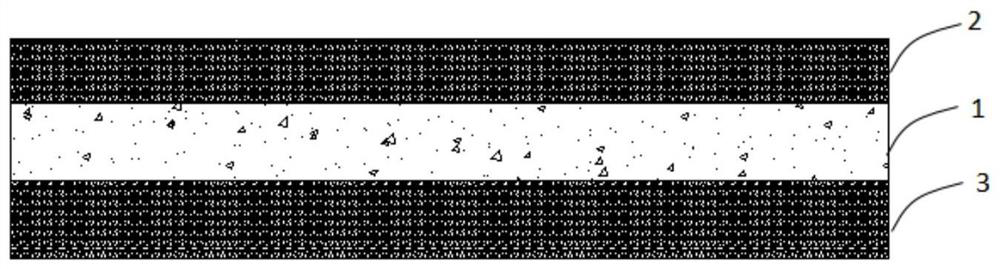

[0064] The gating tube unit disclosed in this application includes a first electrode layer 2, a second electrode layer 3 and a gating tube material layer 1, wherein the gating tube material layer 1 is obtained by sputtering the above gating tube material, and the first electrode 2 is located on the upper surface of the gate material layer 1; the second electrode 3 is located on the lower surface of the gate material layer 1;

[0065] The material of the first electrode layer 2 is aluminum with a thickness of 190 nanometers, the material of the second electrode layer 3 is aluminum with a thickness of 190 nanometers, and the thickness of the gate tube material layer 1 is 20 nanometers.

[0066] Moreover, a transition layer is provided on the upper surface of the gate material layer 1, and the first electrode 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com