Method for preparing red jujube beverage through lactobacillus complex fermentation

A technology of compound milk and bacilli, which is applied in the direction of food ingredients as antimicrobial preservation, food ingredients as antioxidants, food science, etc., can solve the problems of low free phenolic acid content and poor oxidation resistance, and achieve short fermentation cycle and easy fermentation. Effect of separation and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

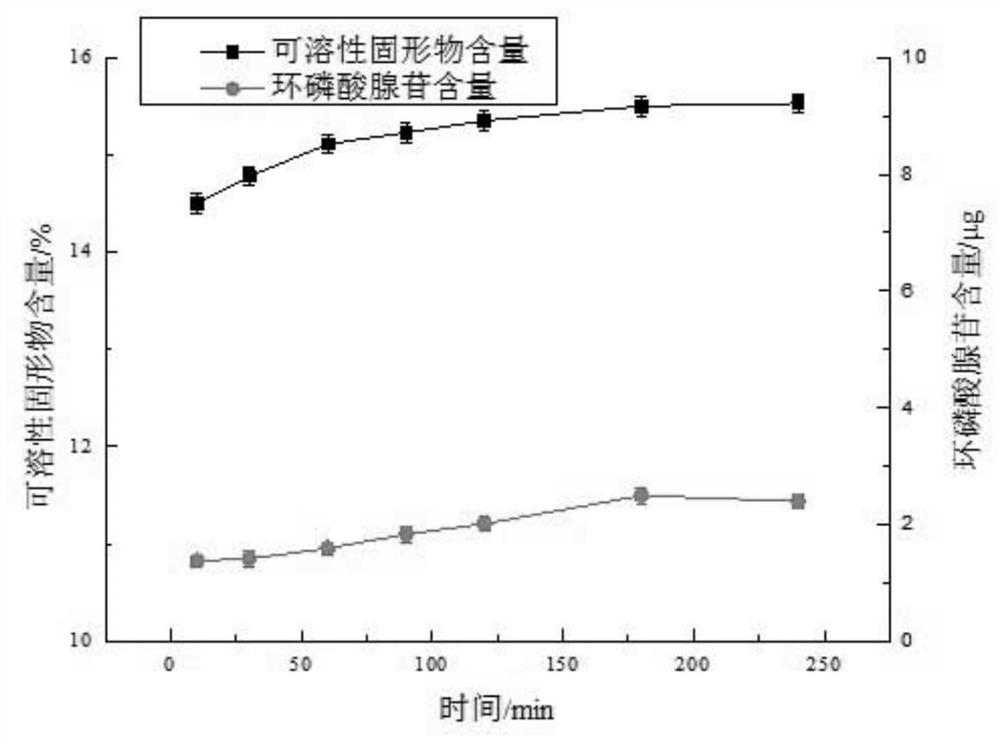

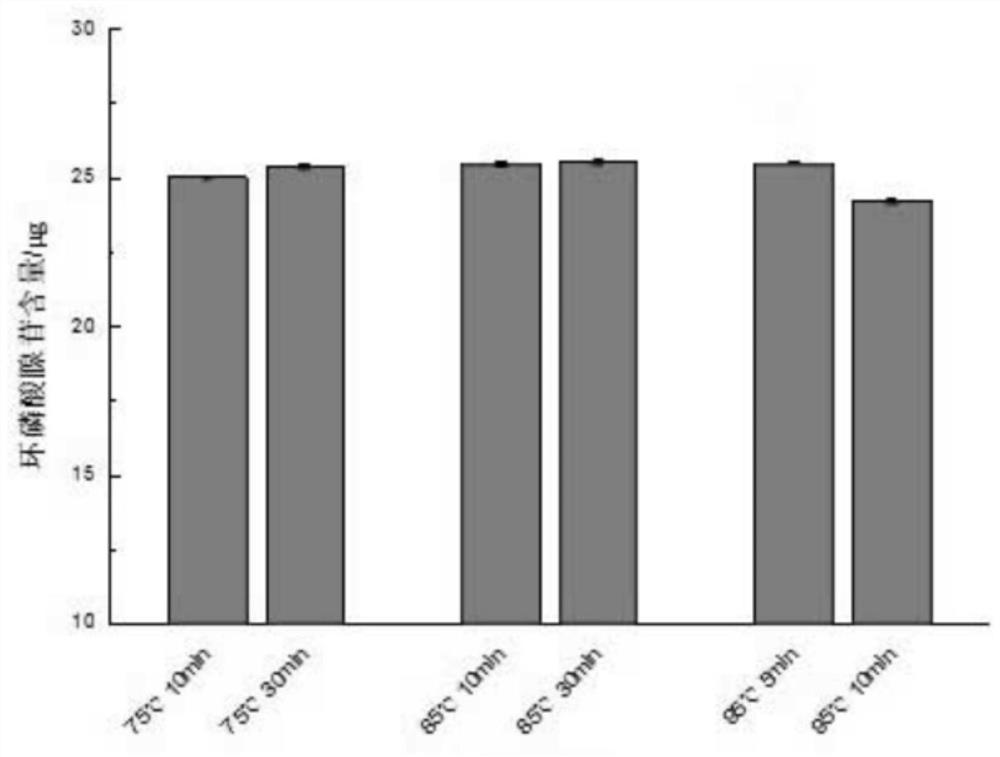

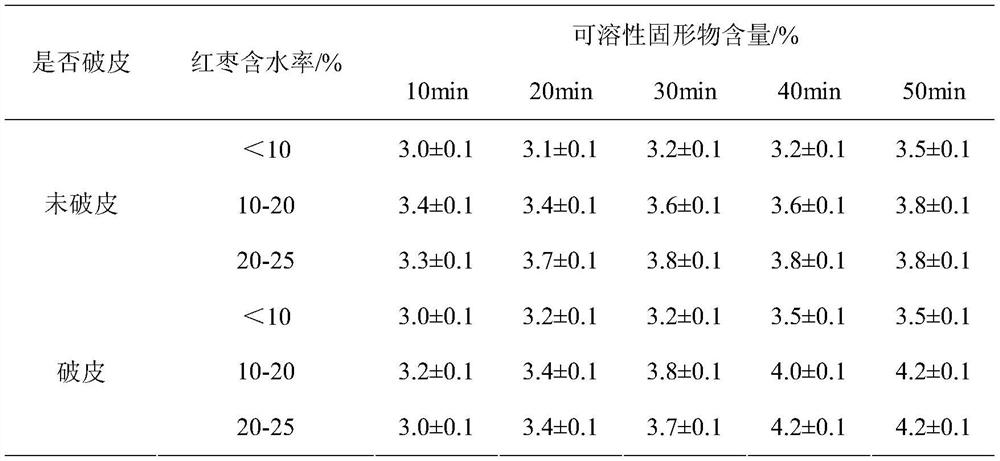

[0034]Example 1, the method for preparing jujube beverage through the fermentation of compound lactobacilli, including selecting dried jujubes with a water content of 20-25%, after selection and cleaning, adding water at 90-95°C and 2.5 times the quality of dried jujubes for precooking For 30 minutes, after the jujube is pitted, it is beaten with a colloid mill. After the slurry is obtained, add water to make it 5 times the mass of the dry jujube. Use sodium bicarbonate to adjust the pH to 4.50. Add cellulase with an activity of 20,000 U / g and 100,000 U / g of pectinase, the two additions are 0.125% of the dry jujube mass, heat up to 50-55°C for 3 hours for enzymolysis, after the enzymolysis is completed, heat up to 95°C for 5 minutes to kill the enzyme, and then cool down to 60°C Centrifuge at -65°C for 20 minutes at 3000 rpm to obtain the original squeezed jujube juice. Adjust the soluble solids in the original jujube clear juice to 14.0°Brix to obtain standardized original ju...

Embodiment 2

[0037] Example 2, the method of preparing jujube beverage through the fermentation of compound lactobacilli, including selecting dried jujubes with a water content of 20-25%, after selection and cleaning, adding water at 90-95°C and 2.5 times the quality of dried jujubes for pre-boiling For 30 minutes, after the jujube is pitted, it is beaten with a colloid mill. After the slurry is obtained, add water to make it 5 times the mass of the dry jujube. Use sodium bicarbonate to adjust the pH to 4.50. Add cellulase with an activity of 20,000 U / g and 100,000 U / g of pectinase, the two additions are 0.125% of the dry jujube mass, heat up to 50-55°C for 3 hours for enzymolysis, after the enzymolysis is completed, heat up to 95°C for 5 minutes to kill the enzyme, and then cool down to 60°C Centrifuge at -65°C for 20 minutes at 3000 rpm to obtain the original squeezed jujube juice. Adjust the soluble solids of the original jujube clear juice to 14.5°Brix to obtain the standardized origin...

Embodiment 3

[0040] Example 3, the method for preparing jujube beverage through the fermentation of compound lactobacilli, including selecting dried jujubes with a water content of 20-25%, after selection and cleaning, adding water at 90-95°C and 2.5 times the quality of dried jujubes for pre-boiling For 30 minutes, after the jujube is pitted, it is beaten with a colloid mill. After the slurry is obtained, add water to make it 5 times the mass of the dry jujube. Use sodium bicarbonate to adjust the pH to 4.50. Add cellulase with an activity of 20,000 U / g and 100,000 U / g of pectinase, the two additions are 0.125% of the dry jujube mass, heat up to 50-55°C for 3 hours for enzymolysis, after the enzymolysis is completed, heat up to 95°C for 5 minutes to kill the enzyme, and then cool down to 60°C Centrifuge at -65°C for 20 minutes at 3000 rpm to obtain the original squeezed jujube juice.

[0041] Adjust the soluble solids of the original jujube clear juice to 15°Brix to obtain the standardize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com