Mask filter layer and preparation method and application thereof

A filter layer and mask technology, applied in applications, textiles and papermaking, clothing, etc., can solve the problems of the decline of the filtration performance of meltblown non-woven fabrics, the inability of masks to effectively protect, and the high bacteria and virus processing capacity, and achieve the restoration of electrostatic adsorption. ability, efficient electrical and thermal conductivity, and the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

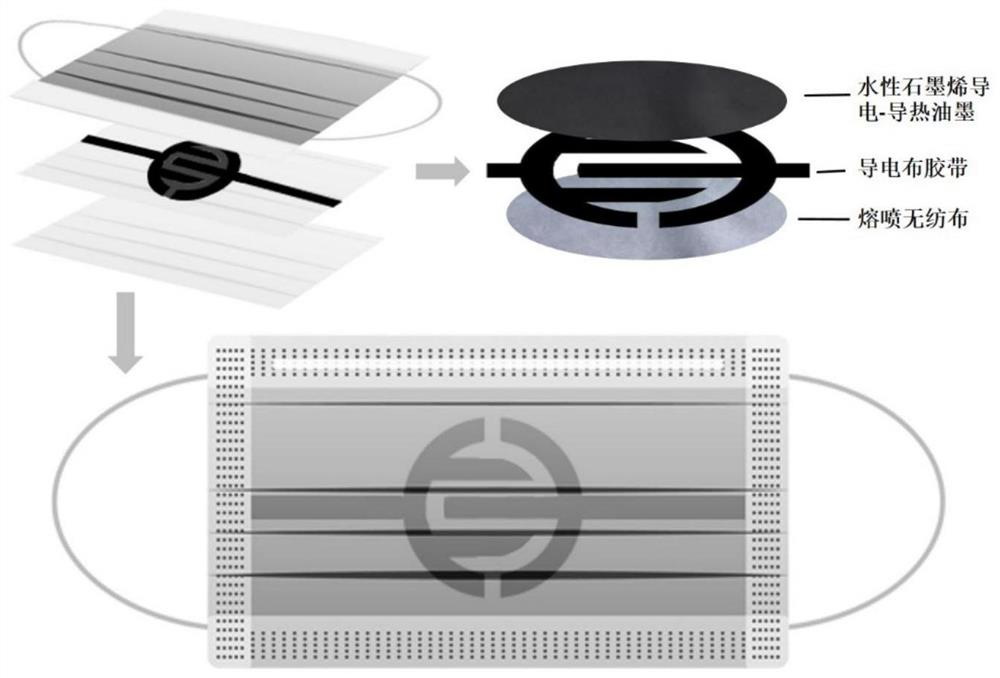

[0052] The present invention also provides the preparation method of above-mentioned mask filter layer, concrete steps are as follows:

[0053] 1. Take a commercialized melt-blown non-woven fabric for surgical masks, and cut it according to the size of the commercial mask.

[0054] 2. Paste the flexible conductive electrode on the surface of the melt-blown non-woven fabric according to the designed pattern. It is necessary to ensure that the conductive electrode broadband is evenly distributed and the conductive electrode is pasted flat to ensure that the current passes evenly.

[0055] 3. Mix water-based modified resin and water-based special conductive grade graphene according to the weight ratio of 5:2 to 5:4, and use a magnetic stirrer to stir for more than 2 hours to configure uniform high-performance conductive-conductive water-based graphene ink.

[0056] 4. Use a coating machine to evenly coat the water-based graphene ink obtained in step 3 on the surface of the melt-...

Embodiment 1

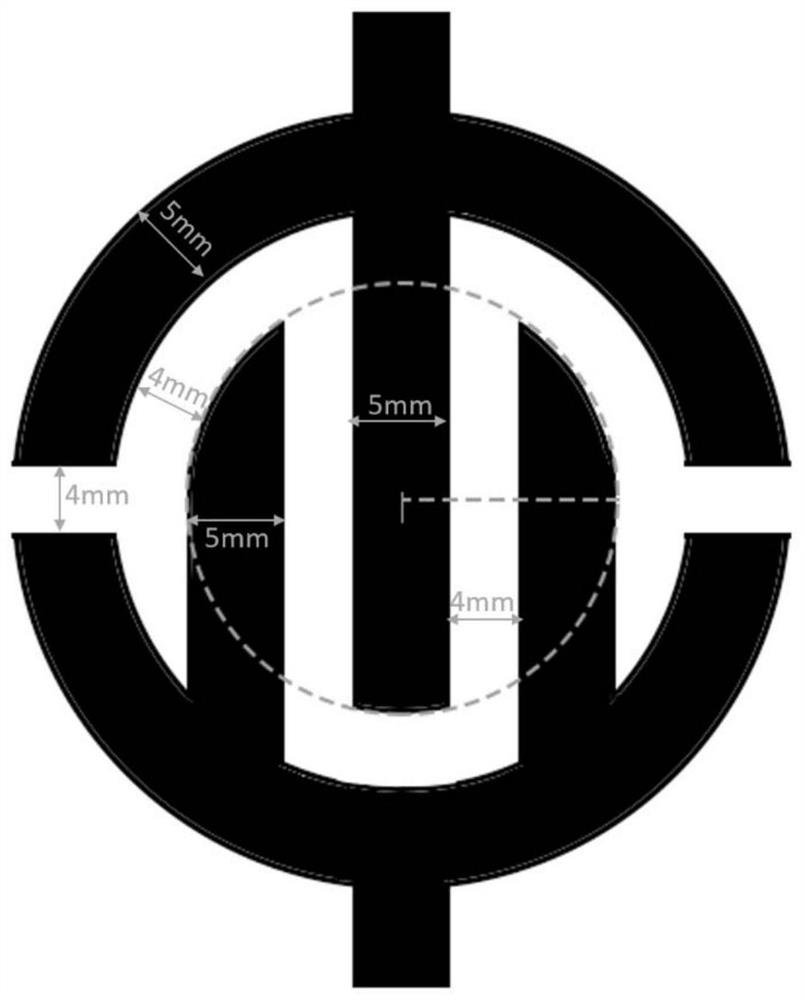

[0062] Apply the flexible conductive cloth tape according to the designed pattern ( figure 2 shown) pasted on the surface of the melt-blown non-woven fabric. Mix the water-based modified resin and water-based special conductive grade graphene according to the weight ratio of 5:3, and use a magnetic stirrer to stir for more than 2 hours to make them evenly mixed. Then the above mixed solution is coated on the surface of the melt-blown non-woven fabric with flexible conductive electrodes (0.0126g / cm 2 ), and dry naturally.

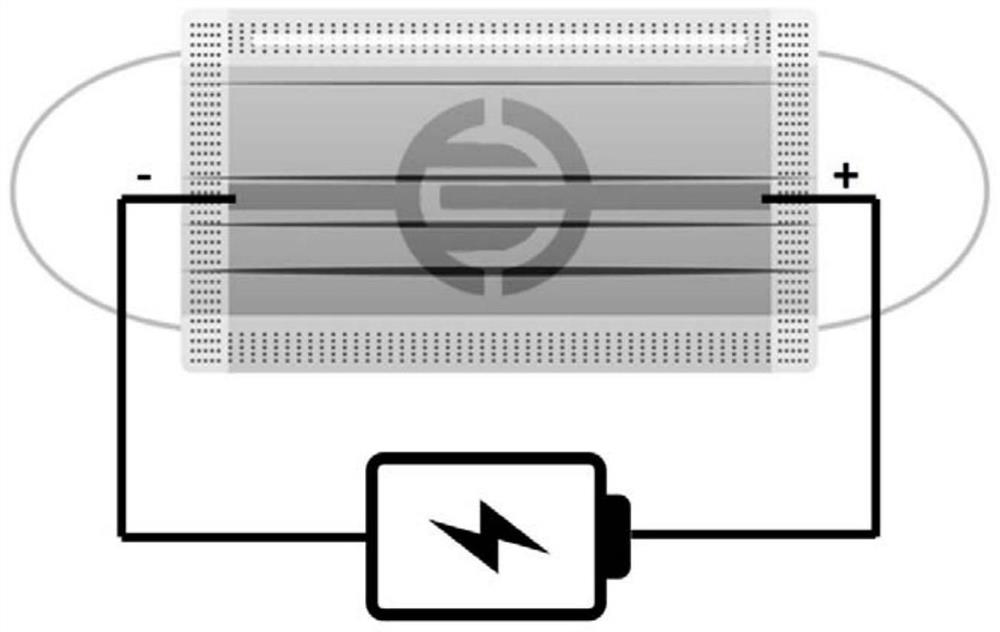

[0063] The two poles of the conductive electrode of the improved filter layer made above are respectively connected to the positive and negative poles of the DC voltage source, such as image 3 As shown, the voltage is 3V, keep the power on for 30 minutes, then disconnect the power.

[0064] Figure 4 It is a curve graph of the temperature changing with time for the above-mentioned improved filter layer under the voltage of 3V. It can be seen that the ...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 lies in that the structures of the conductive electrodes are different.

[0068] Apply flexible conductive cloth tape to the Image 6 The structure shown is pasted on the surface of the meltblown nonwoven. Mix the water-based modified resin and water-based special conductive grade graphene according to the weight ratio of 5:3, and use a magnetic stirrer to stir for more than 2 hours to make them evenly mixed. Then the above mixed solution is coated on the surface of the melt-blown non-woven fabric with flexible conductive electrodes (0.0126g / cm 2 ), and dry naturally.

[0069] Connect the two poles of the conductive electrode to the positive and negative of the DC voltage source respectively, with a voltage of 3V, and keep the power on for 30 minutes, such as Figure 7 As shown, non-uniform heat generation on the lower surface of the electrode structure was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com