Sulfonated nano fibroin-cellulose mixed film and preparation method and application thereof

A technology of sulfonated nano and silk fibers, which is applied in the field of recovery of Candida lipase, can solve the problems of loss of enzyme activity, inability to reuse, complicated process, etc., and achieve excellent reusability, good application prospects, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

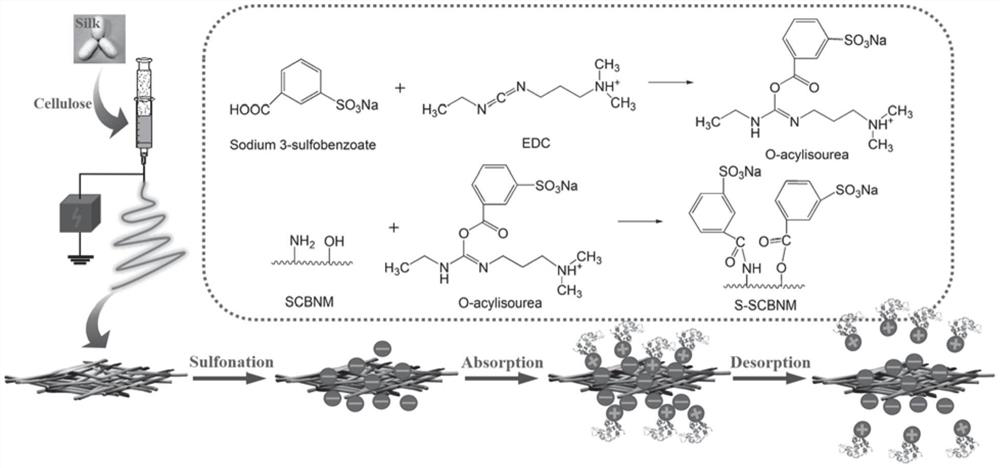

[0044] A preparation method of sulfonated nano silk fibroin-cellulose mixed membrane and its application in reclaiming Candida lipase, such as figure 1 As shown, the specific steps are as follows:

[0045] 1) Using silk fibroin and cellulose acetate as raw materials, electrospinning technology is used to prepare nano silk fibroin-cellulose mixed membrane materials through blending;

[0046] 1-1) Degumming silkworm cocoons with sodium carbonate solution at high temperature to obtain silk fibers; the concentration range of the sodium carbonate solution is 0.2wt%, and the temperature range is 85°C;

[0047]1-2) Dissolve silk fibroin fiber in lithium bromide solution, after dialysis and filtration, take it out and freeze-dry to obtain regenerated silk fibroin; the concentration range of lithium bromide solution is 7mol L -1 , the parts by weight of silk fiber and lithium bromide solution are respectively: 1 part of silk fiber, 700 parts of lithium bromide solution;

[0048] 1-3)...

Embodiment 2

[0061] A preparation method of sulfonated nano silk fibroin-cellulose mixed membrane and its application in recycling Candida lipase, the specific steps are as follows:

[0062] 1) Using silk fibroin and cellulose acetate as raw materials, electrospinning technology is used to prepare nano silk fibroin-cellulose mixed membrane materials through blending;

[0063] 1-1) Degumming silkworm cocoons with sodium carbonate solution at high temperature to obtain silk fibers; the concentration range of the sodium carbonate solution is 0.7wt%, and the temperature range is 100°C;

[0064] 1-2) Dissolve silk fibroin fiber in lithium bromide solution, after dialysis and filtration, take it out and freeze-dry to obtain regenerated silk fibroin; the concentration range of lithium bromide solution is 9mol L -1 , the parts by weight of silk fiber and lithium bromide solution are respectively: 3 parts of silk fiber, 900 parts of lithium bromide solution;

[0065] 1-3) Dissolving regenerated si...

Embodiment 3

[0078] A preparation method of sulfonated nano silk fibroin-cellulose mixed membrane and its application in recycling Candida lipase, the specific steps are as follows:

[0079] 1) Using silk fibroin and cellulose acetate as raw materials, electrospinning technology is used to prepare nano silk fibroin-cellulose mixed membrane materials through blending;

[0080] 1-1) Degumming silkworm cocoons with sodium carbonate solution at high temperature to obtain silk fibers; the concentration range of the sodium carbonate solution is 0.5wt%, and the temperature range is 100°C;

[0081] 1-2) Dissolve silk fibroin fiber in lithium bromide solution, after dialysis and filtration, take it out and freeze-dry to obtain regenerated silk fibroin; the concentration range of lithium bromide solution is 8mol L -1 , the parts by weight of silk fiber and lithium bromide solution are respectively: 1.4 parts of silk fiber, 800 parts of lithium bromide solution;

[0082] 1-3) Dissolving regenerated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com