Printing and dyeing device used for textile production line and use method of printing and dyeing device

A technology for textiles and production lines, applied in the field of printing and dyeing devices for textile production lines, can solve the problems of uneven dyeing, poor practicability, and single function, and achieve the effects of uniform dyeing, strong practicability, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

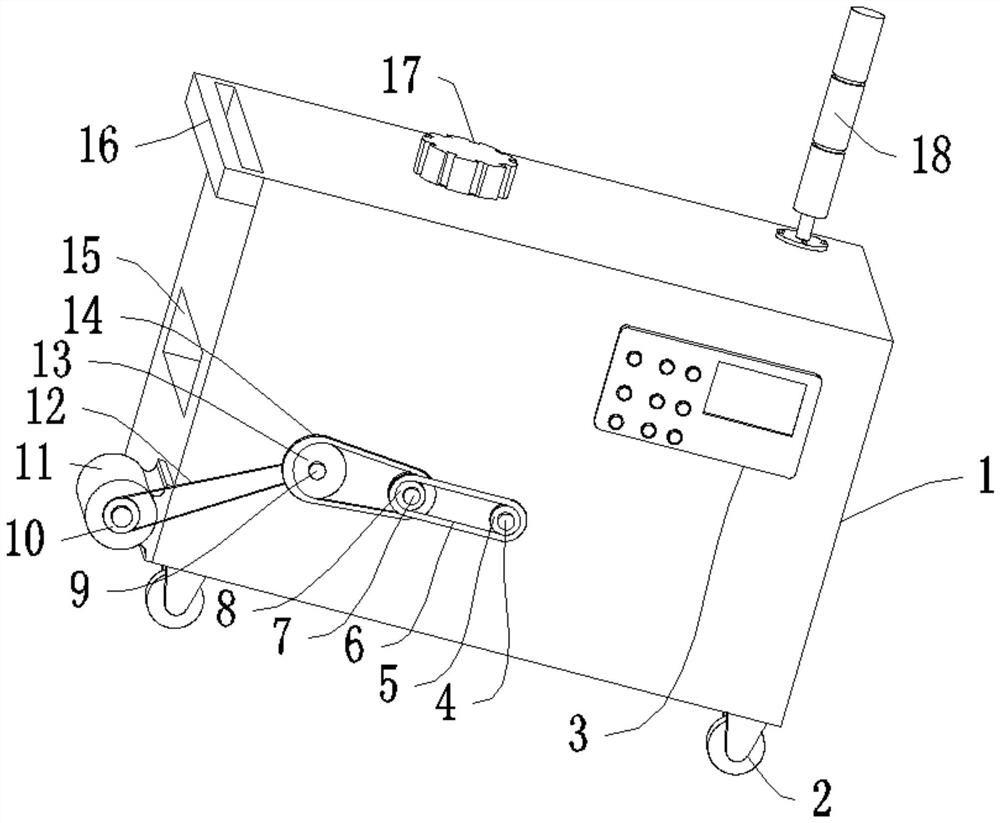

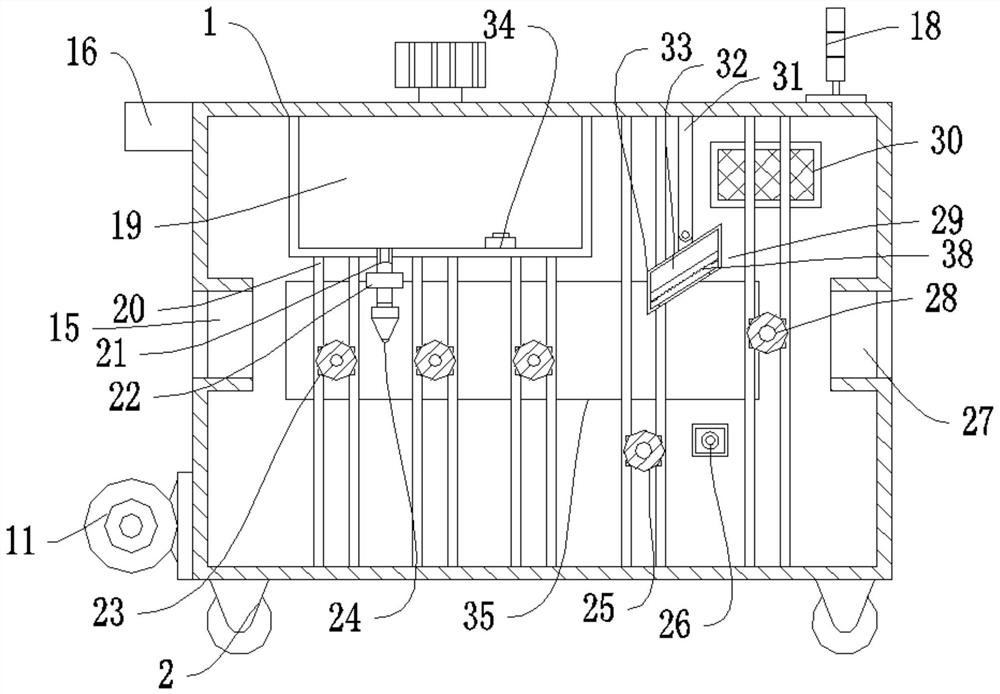

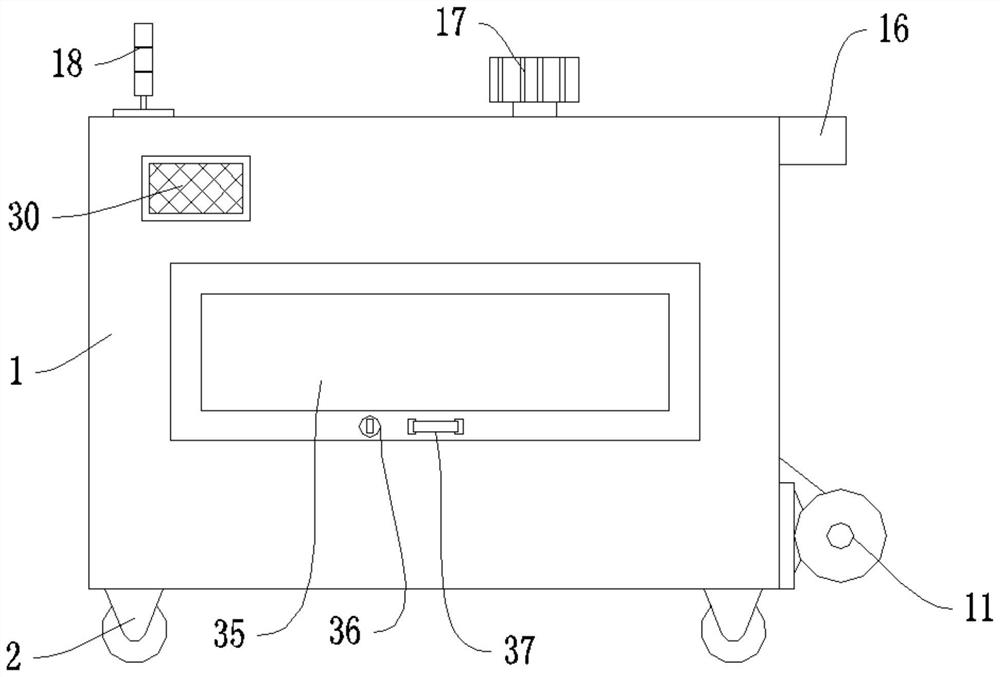

[0039] Example: such as Figure 1-Figure 4 As shown, the printing and dyeing device for a textile production line includes a box body 1, a universal wheel 2, an alarm light 18, and a drying device 29;

[0040] The bottom of the box 1 is provided with a universal wheel 2, and the front end of the box 1 is provided with a controller 3. The controller 3 is used to control whether the actuator operates or not. The controller 3 and the box 1 are connected by screws. The box 1 There is a warning light 18 on the top of the top, and the warning light 18 plays a warning role. One side of the warning light 18 is provided with an upper cover 17, and one side of the side of the box body 1 is provided with a push-pull handle 16, and the push-pull handle 16 and the box body 1 pass through Screw connection, the bottom of the push-pull handle 16 is provided with a feed inlet 15, the bottom of the feed inlet 15 is provided with a motor 11, the motor 11 is used to provide power, the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com