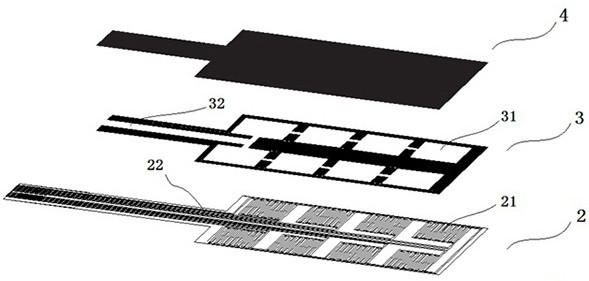

Flexible tactile pressure sensor

A pressure sensor and tactile technology, which is applied in the measurement of properties and force of piezoresistive materials, and the measurement of force, etc., can solve the problems of high cost, deformation of silicone, and inability to meet the requirements at the same time, and achieve easy assembly and integration. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

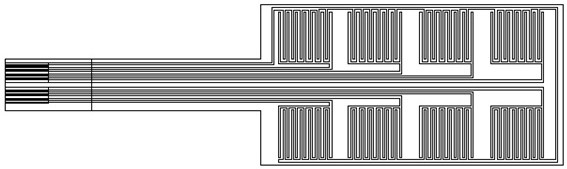

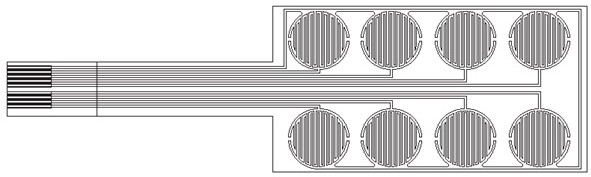

Method used

Image

Examples

Embodiment 4

[0054]The flexible tactile pressure sensor described in Embodiment 4 is incomplete due to the incomplete surface of the sensing material layer 4, which will cause failure when used in a liquid environment. Therefore, a layer of shielding layer 5 matching its size and shape can be arranged on its surface to be suitable for liquid environment. The shielding layer 5 can be made of waterproof and breathable polymer materials or polymer composite materials, such as PET, TPU, PVDC, etc. The thickness of the shielding layer 5 can be 1 μm-500 μm, preferably 10 μm-100 μm. During production, the periphery of the shielding layer 5 can be fixed on the periphery of the sensing material layer 4 by means of pasting, laser welding, etc., so that the shielding layer 5 is covered on the surface of the sensing material layer 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap