Takifugu rubripes biological preservative as well as preparation method and application of takifugu rubripes biological preservative

A technology of pufferfish and biological preservatives, applied in food science, preservation of meat/fish with chemicals, preservation of meat/fish through freezing/cooling, etc., can solve the problem of no natural preservatives and color changes of pufferfish , quality decline and other issues, to achieve significant fresh-keeping effect, simple production process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

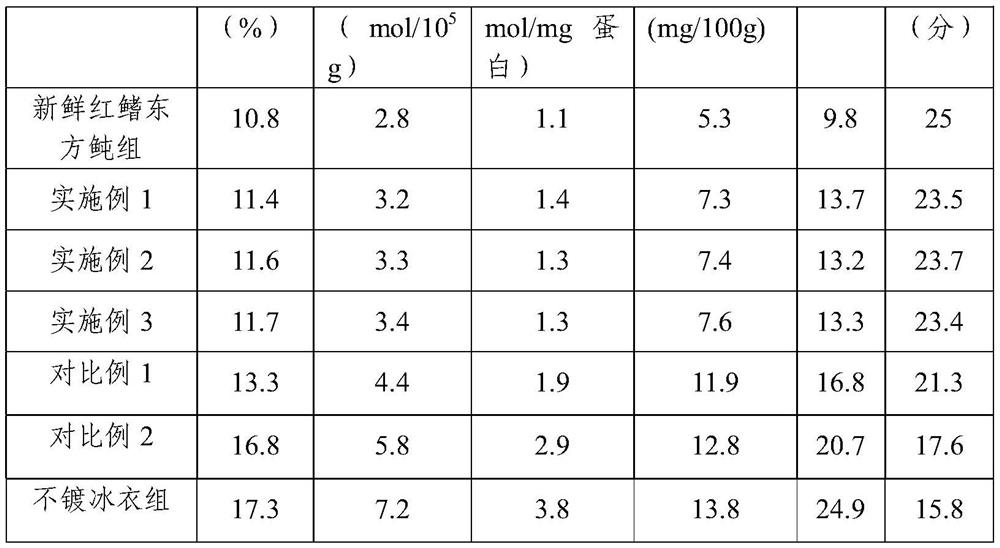

Embodiment 1

[0020] Present embodiment provides a kind of fresh-keeping method of red fin puffer, comprising the following steps:

[0021] 1) Choose 50 grams of frozen fish skin, thaw it at 10-12°C, wash the fish skin with clean water that meets the drinking water hygiene standard, beat the fish skin with a beater after cleaning the fish skin, add the weight of the fish skin 3.5 times of water, boiled at 110°C for 120 minutes. Then adjust the temperature to 65° C., and use an ultrasonic generator to process ultrasonic waves (frequency 60 kH) for 15-25 minutes to obtain fish skin slurry.

[0022] 2) According to the weight percentage ratio of 0.1% of fish skin weight, add compound protease to (1) for enzymolysis, protease (alkaline protease+neutral protease+papain) composition, the mass ratio between them is 1:1: 2) Carry out the enzymatic hydrolysis reaction at 50°C for 0.5h, cool to room temperature, centrifuge at 5000g for 5 minutes, collect the supernatant, adjust the protein content t...

Embodiment 2

[0026] Present embodiment provides a kind of fresh-keeping method of red fin puffer, comprising the following steps:

[0027] 1) Select 500 grams of frozen tilapia fish skin, thaw it at 10-12 °C, wash the fish skin with clean water that meets the drinking water hygiene standards, and beat the fish skin with a beater after cleaning the fish skin, add Water that is 4.0 times the weight of fish skin is boiled at 121°C for 60 minutes. Then adjust the temperature to 75° C., and use an ultrasonic generator to process ultrasonic waves (frequency 40 kH) for 25 minutes to obtain fish skin slurry.

[0028] 2) According to the weight percentage ratio of 0.2% of fish skin weight, add composite protease to (1) for enzymolysis, protease (alkaline protease+neutral protease+papain) composition, the mass ratio between them is 2:1: 1) Carry out the enzymatic hydrolysis reaction at 60°C for 1.0h, cool to room temperature, centrifuge at 4000g for 8 minutes, collect the supernatant, adjust the pr...

Embodiment 3

[0032] Present embodiment provides a kind of fresh-keeping method of red fin puffer, comprising the following steps:

[0033] 1) Select 1000 grams of frozen tilapia skin, thaw it at 10-12°C, wash the skin with clean water that meets the sanitary standards for drinking water, and beat the skin with a beater after cleaning the skin, add Water that is 4.5 times the weight of fish skin is boiled at 100°C for 120 minutes. Then the temperature was adjusted to 75°C, and an ultrasonic generator was used to process ultrasonic waves (60kH frequency) for 15 minutes to obtain fish skin slurry.

[0034] 2) According to the weight percentage ratio of 0.3% of fish skin weight, add composite protease to (1) for enzymolysis, protease (alkaline protease+neutral protease+papain) composition, the mass ratio between them is 1:1: 1) Carry out the enzymatic hydrolysis reaction at 55°C for 1.0h, cool to room temperature, centrifuge at 5000g for 4 minutes, collect the supernatant, adjust the protein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com