Automobile front wall noise elimination part and preparation method thereof

A technology for parts and automobiles, applied in the field of automobile front wall muffler parts and their preparation, can solve the problems of difficult to effectively improve sound absorption performance, no fineness, no sound insulation performance, etc., so as to improve the driving experience and achieve light Quantification, effect of excellent sound absorption and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

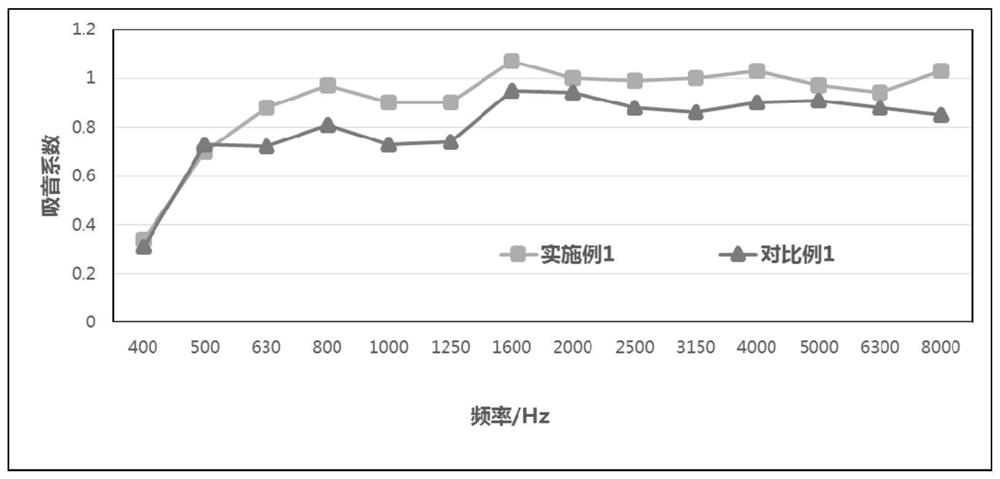

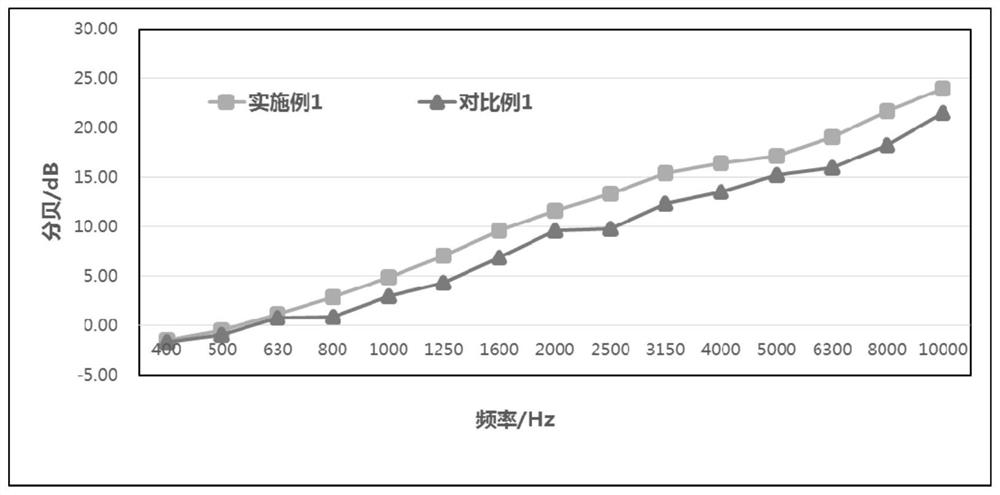

Embodiment 1

[0062] This embodiment provides a noise-absorbing part for the front wall of an automobile. The noise-absorbing part includes a sound-insulating layer, an adhesive layer, and a sound-absorbing layer in sequence from the outside to the inside, and the sound-insulating layer and the sound-absorbing layer are composed of composite fibers;

[0063] The composite fiber includes a first fiber and a second fiber, the fineness of the first fiber is greater than that of the second fiber, the length of the second fiber is 40 mm, and the linear density is 0.25 dtex.

[0064] The grammage of the sound insulation layer is 1000g / m 2 , the thickness is 8mm.

[0065] The gram weight of the sound-absorbing layer is 1000g / m 2 , the thickness is 15mm.

[0066] The first fiber includes synthetic fiber and natural fiber, the synthetic fiber is polyester fiber, and the natural fiber is cotton fiber.

[0067] The first fiber has a length of 60mm and a linear density of 6dtex.

[0068] The second...

Embodiment 2

[0072] This embodiment provides a noise-absorbing part for the front wall of an automobile. The noise-absorbing part includes a sound-insulating layer, an adhesive layer, and a sound-absorbing layer in sequence from the outside to the inside, and the sound-insulating layer and the sound-absorbing layer are composed of composite fibers;

[0073] The composite fiber includes a first fiber and a second fiber, the fineness of the first fiber is greater than that of the second fiber, the length of the second fiber is 30 mm, and the linear density is 0.05 dtex.

[0074] The grammage of the sound insulation layer is 600g / m 2 , the thickness is 5mm.

[0075] The gram weight of the sound-absorbing layer is 800g / m 2 , the thickness is 10mm.

[0076] The first fiber includes synthetic fiber and natural fiber, the synthetic fiber is polyacrylonitrile fiber, and the natural fiber is cotton fiber.

[0077] The length of the first fiber is 40mm, and the linear density is 4dtex.

[0078] ...

Embodiment 3

[0082] This embodiment provides a noise-absorbing part for the front wall of an automobile. The noise-absorbing part includes a sound-insulating layer, an adhesive layer, and a sound-absorbing layer in sequence from the outside to the inside, and the sound-insulating layer and the sound-absorbing layer are composed of composite fibers;

[0083] The composite fiber includes a first fiber and a second fiber, the fineness of the first fiber is greater than that of the second fiber, the length of the second fiber is 50 mm, and the linear density is 0.5 dtex.

[0084] The grammage of the sound insulation layer is 400g / m 2 , the thickness is 3mm.

[0085] The gram weight of the sound-absorbing layer is 600g / m 2 , the thickness is 6mm.

[0086] The first fibers include synthetic fibers and natural fibers, the synthetic fibers are polyamide fibers, and the natural fibers are cotton fibers.

[0087] The first fiber has a length of 80mm and a linear density of 8dtex.

[0088] The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com