Improved heat pump vacuum low-temperature evaporation and concentration system

An evaporation concentration system, vacuum and low temperature technology, applied in the direction of heating water/sewage treatment, special treatment targets, chemical instruments and methods, etc., can solve the problems of distilled water temperature rise, temperature rise, high-concentration industrial wastewater outsourced disposal costs, etc. Achieve good water quality and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

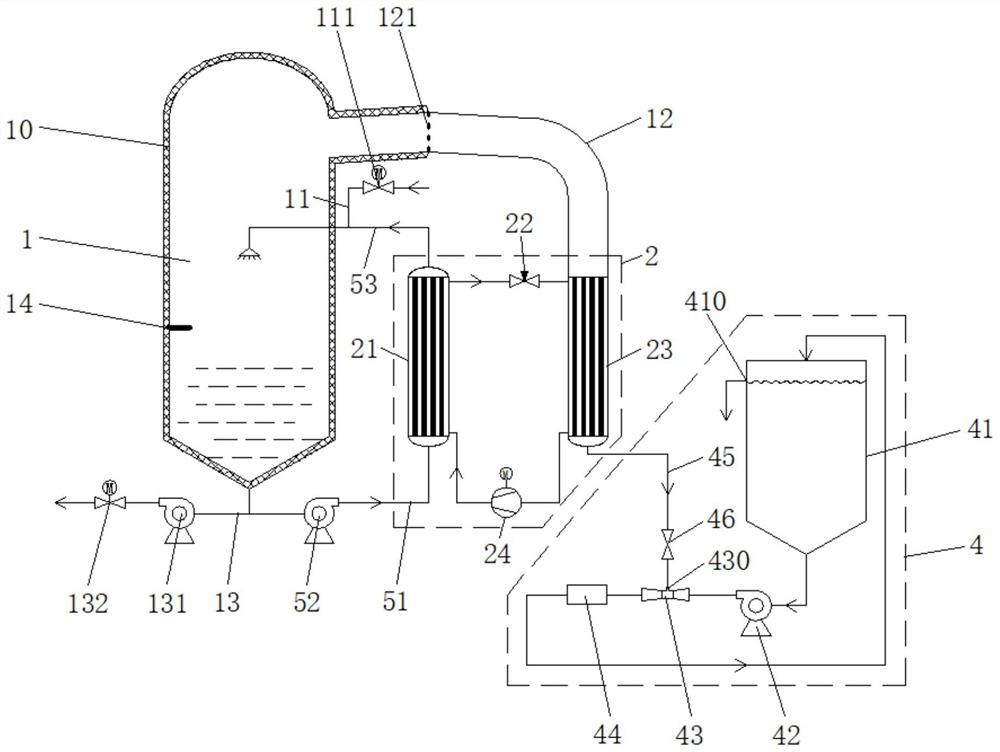

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] like figure 1 as shown in figure 1 As shown, an improved heat pump vacuum low-temperature evaporation and concentration system includes an evaporation tank 1, a heating Carnot cycle system 2, and a mixed gas and condensed water removal system 4 containing non-condensable gas. The upper part of the evaporation tank 1 is connected with a waste water inlet pipeline 53 and a steam discharge pipeline 12 , and a liquid level gauge 14 is arranged in the middle of the evaporation tank 1 . The waste water inlet pipeline 53 is provided with a non-evaporated and concentrated waste water replenishment branch 11 , and the non-evaporated and concentrated waste water replenishment branch 11 is provided with a feed valve 111 . A concentrated liquid discharge branch 13 is provided on the pipeline between the bottom of the evaporation tank 1 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com