Vehicle type continuous ironmaking water-slag separation environment-friendly device

An environmental protection device and water slag technology, which is applied in the direction of recycling technology and process efficiency improvement, can solve the problems of workers having to operate grab buckets on site, hidden dangers of water circulation process, and difficult to grab scum, so as to improve operating efficiency and save energy. Good energy efficiency and short slag-water separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

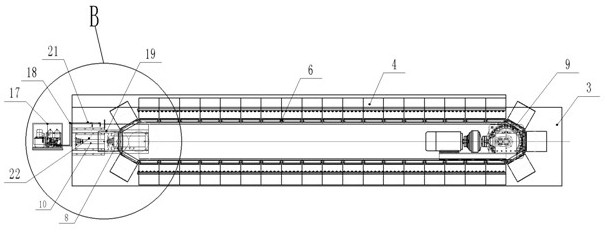

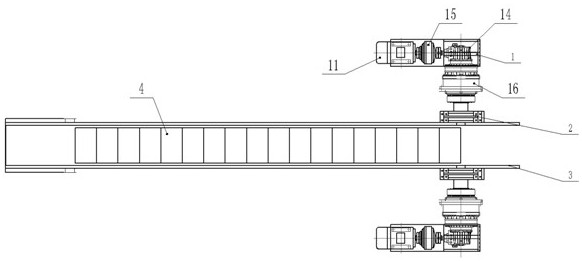

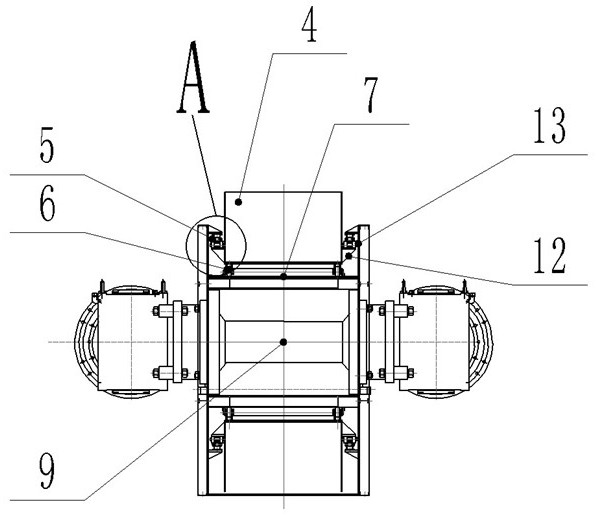

[0022] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

[0023] see Figure 1-6 , a car-type continuous iron-making slag separation environmental protection device, including a motor drive device 1, a loading trolley 4, a tail sprocket 8, a head sprocket 9, a reducer 14, a hydraulic pump station 17 and a third connecting pipe 22; The left side of the head sprocket 9 is provided with a tail sprocket 8, the head sprocket 9 and the tail sprocket 8 are at the same height, and the tail sprocket 8 and the head sprocket 9 are connected by a running chain 6 to run A plurality of loading trolleys 4 are evenly distributed on the chain 6. The loading trolleys 4 can load the water slag produced when the blast furnace smelts steel, and transport the water slag through the operation of the chain 6. The loading trolley 4 is a rectangular box with an opening on the top. Dolly, the four side walls of the loading trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com