Comprehensive thermal management system of large alkaline water electrolysis hydrogen production device

A technology of thermal management system and hydrogen production device, which is applied in the direction of electrolysis process, electrolysis components, heat storage equipment, etc., can solve the problem that it is difficult to meet the long-term operation of the electrolysis hydrogen production system, the comprehensive thermal efficiency of the electrolyzer cannot improve the hydrogen production efficiency, and no consideration is given to it. Comprehensive utilization of waste heat from electrolysis hydrogen production to avoid heat loss, reduce lye consumption, and reduce atomization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

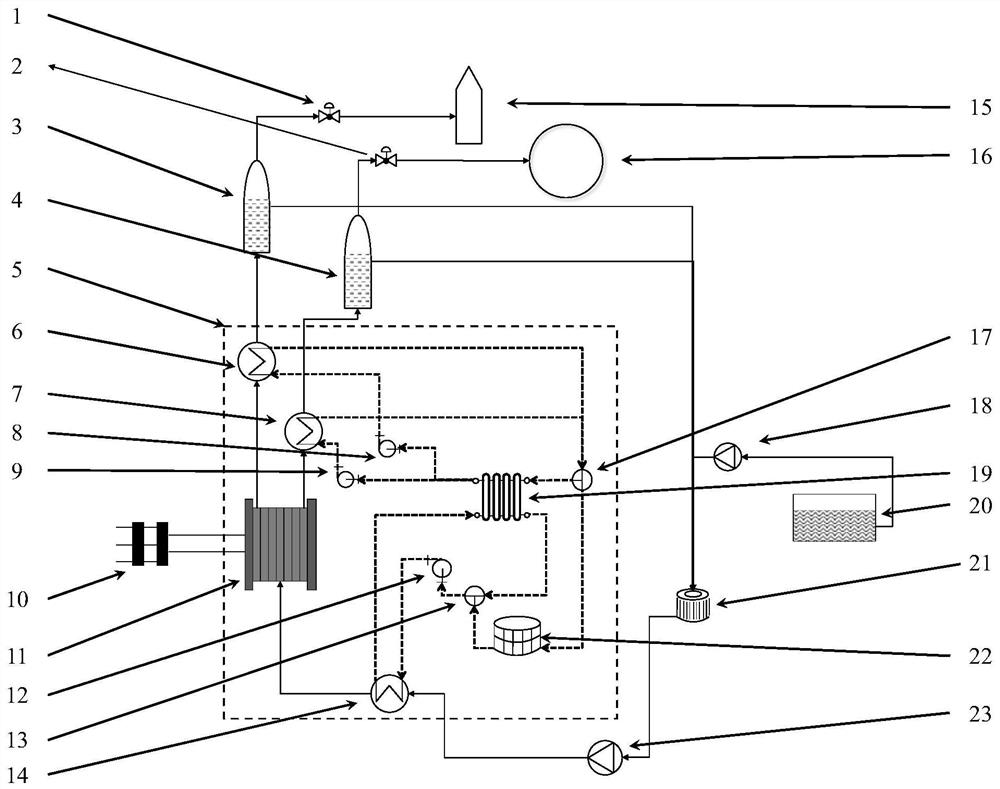

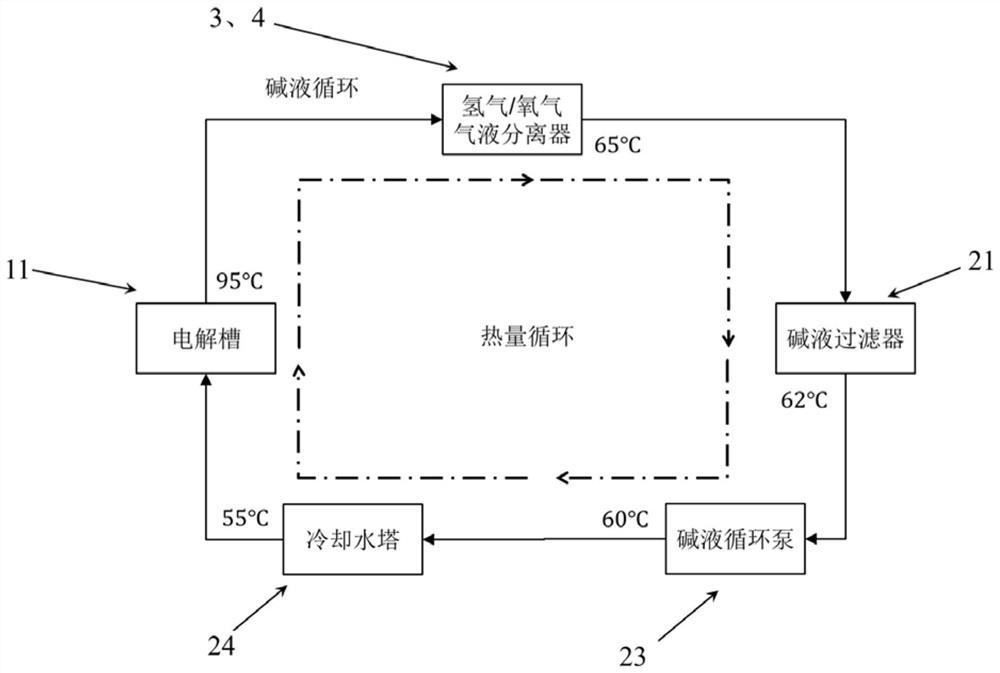

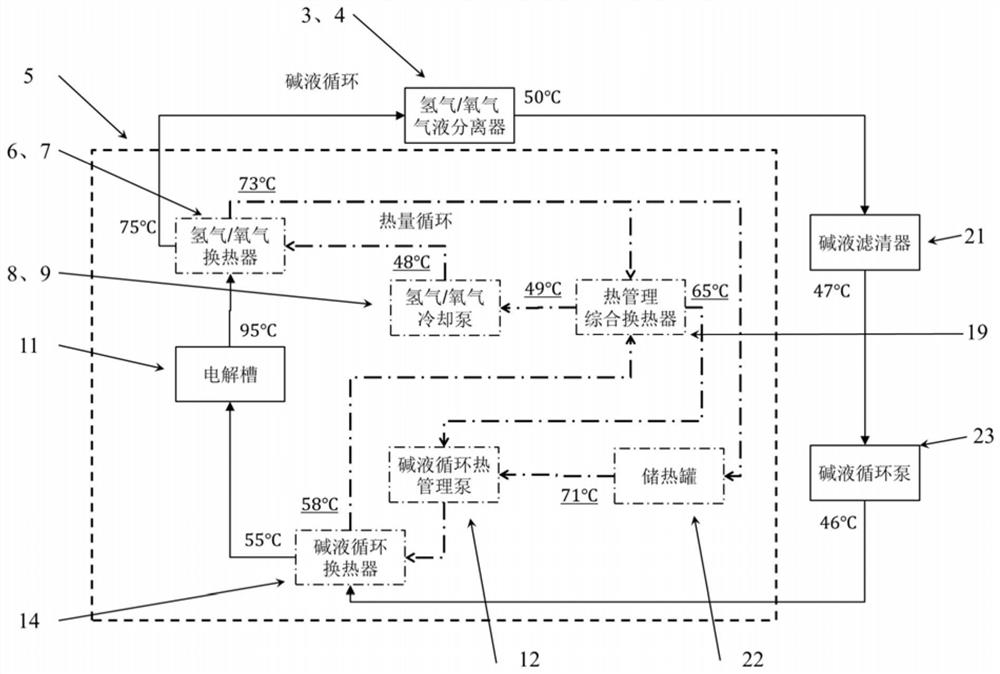

[0030] Such as figure 1 As shown, a comprehensive thermal management system of a large-scale alkaline electrolyzed water hydrogen production device, the system includes an alkaline electrolyzed water hydrogen production device, an alkaline electrolyzed water hydrogen production device includes an electrolytic cell 11 and a gas-liquid separator, and the gas-liquid separator The lye output end of the lye is connected to the electrolyzer 11 through the lye circulation loop, and the system also includes a heat management device, which includes a heat management integrated heat exchanger 19, a gas-liquid separation heat exchanger and an lye circulation heat exchanger 14 , the gas-liquid separation heat exchanger is arranged between the electrolytic cell 11 and the gas-liquid separator, the lye circulation heat exchanger 14 is arranged in the lye circulation loop, the gas-liquid separation heat exchanger and the thermal management comprehensive heat exchanger 19 are exchanged The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com