Device for grabbing and removing foreign fibers in textile fibers

A technology for textile fibers and foreign fibers, which is applied in the field of devices capable of detecting and removing foreign fibers in textile fibers, and can solve problems such as being affected by human factors, reducing the removal rate of foreign fibers, and damage to the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

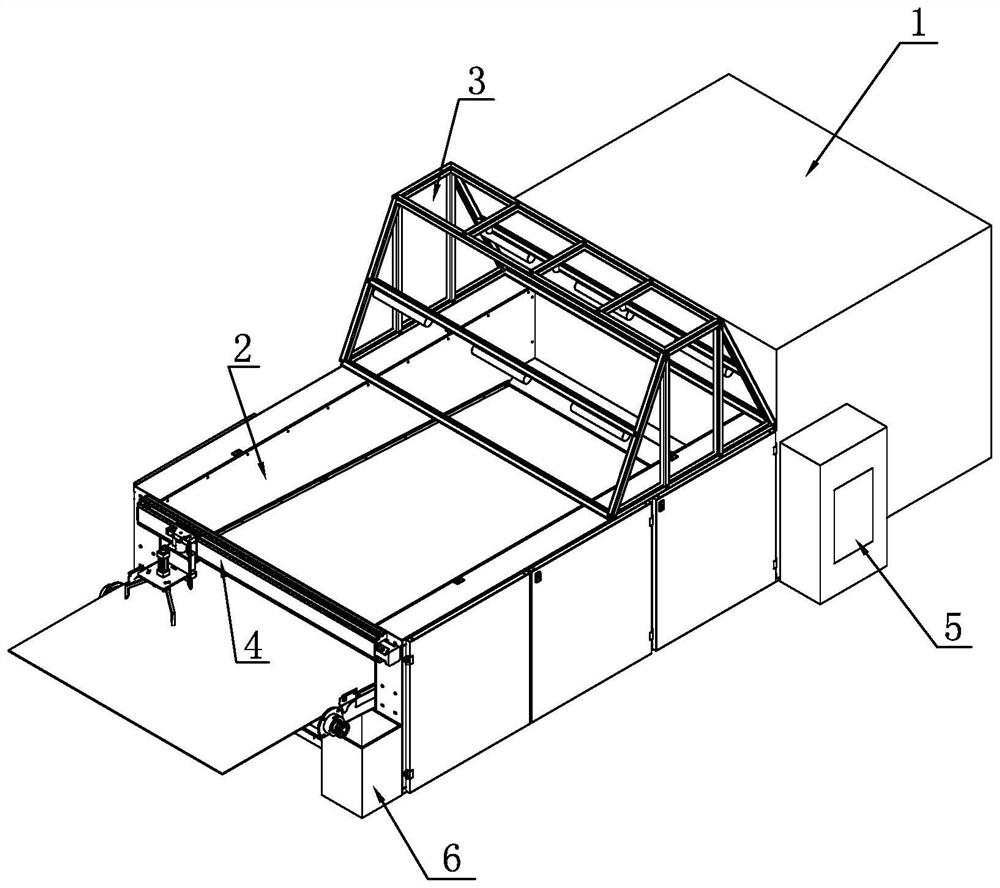

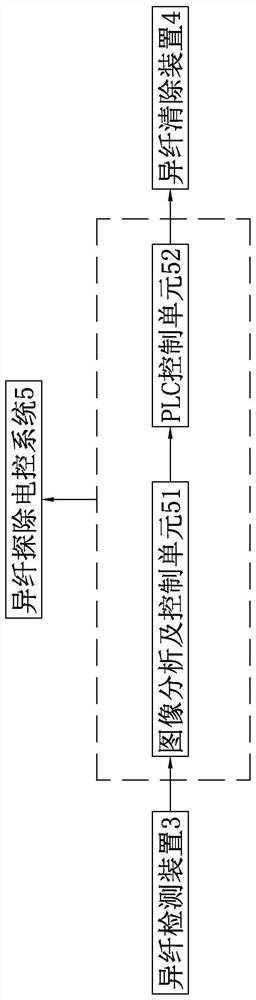

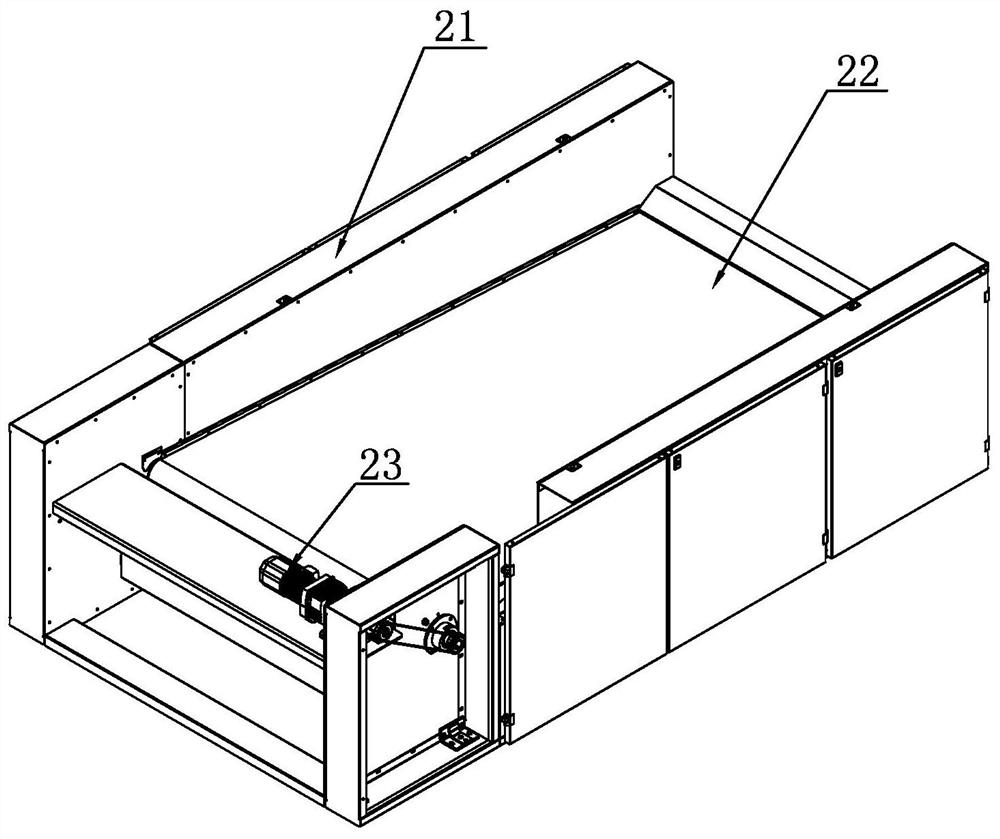

[0035] Embodiment 1: as figure 1 Shown is a schematic diagram of the structure of the present invention for use with a multi-compartment blending machine, including a multi-compartment blending machine body 1, a cotton conveying device 2, a foreign fiber detection device 3, the present invention 4, a foreign fiber detection and removal electric control system 5 and The foreign fiber collection bag 6, the foreign fiber detection device 3 and the present invention 4 are installed on the cotton conveying device 2, and the foreign fiber detection and removal electric control system 5 controls the foreign fiber detection device 3 and the present invention 4; the cotton conveying device 2 is as image 3 As shown, it includes a frame 21, a cotton curtain 22, and a reduction motor 23, wherein the frame 21 is installed at the exit position of the main body 1 of the multi-compartment mixing machine, and the reduction motor 23 drives the cotton transmission curtain 22 to circulate at a un...

Embodiment 2

[0044] Embodiment 2: In Embodiment 1, a reflective plate is installed on the shooting shade lampshade 34 , and the reflective plate performs uniform reflection on the light emitted by the illuminating lamp 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com