Method for testing voltage-withstanding insulation of total anode of lithium battery module to shell

A test method and technology of withstand voltage insulation, applied in the direction of testing circuits, testing dielectric strength, measuring electricity, etc., can solve the problems of difficulty in recycling and reuse of cells, troublesome, increase production costs, etc., to improve the overall testing efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

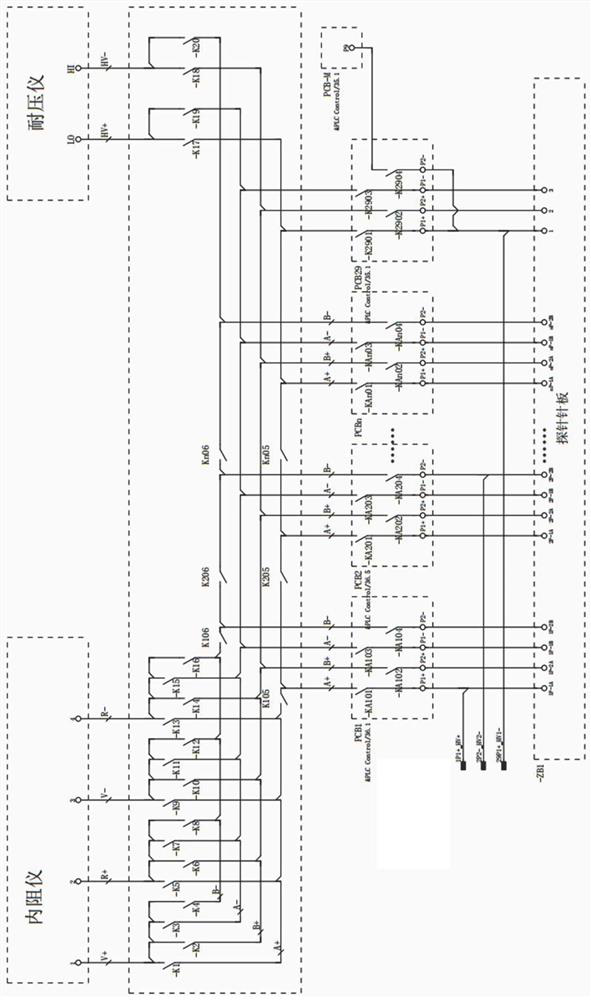

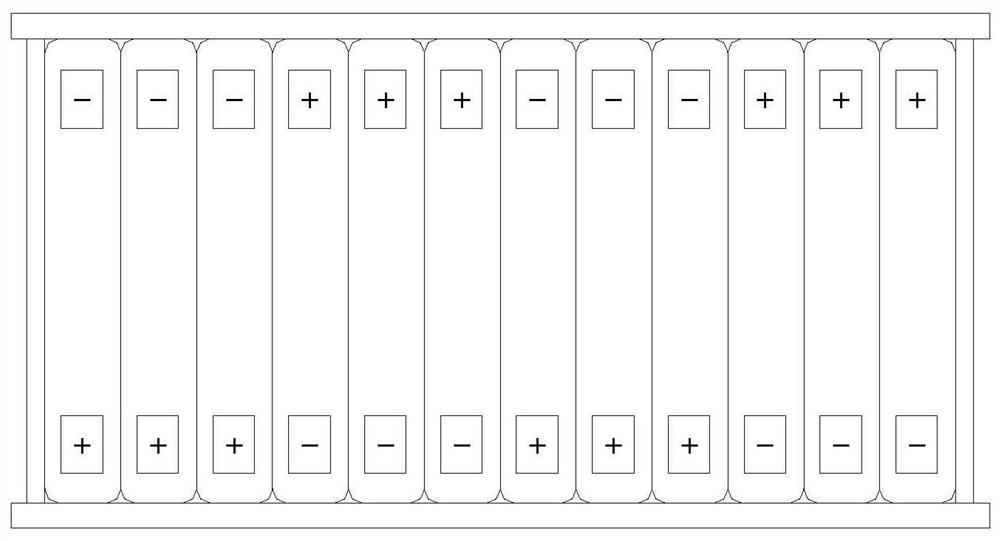

[0017] The present invention optimizes the low-voltage insulation test system through the modification of the relay circuit board, changes the circuit connecting the positive and negative poles of each cell through the switching of the relay, and uses probes, high-voltage silicone wires, and printed circuits in the relay board to simulate BusBar welding. The series-parallel connection state of the rear battery core realizes the electrical performance test between the simulated total positive electrode of the battery core and the shell before BusBar welding.

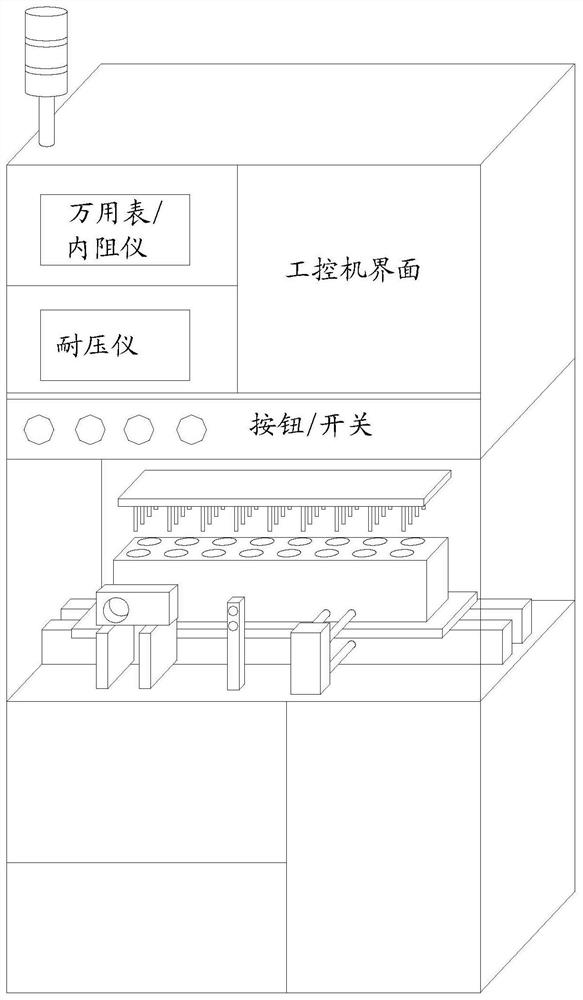

[0018] like figure 1 As shown, the low-voltage insulation test system includes industrial computer, PLC, withstand voltage tester, internal resistance tester, relay board and other instruments and meters, as well as test bed of needles, etc.

[0019] In addition to the traditional test items, the present invention can switch the high-voltage relay on the relay board to pass the positive / negative electrodes of the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com