Method for continuously extracting grease, flavone and polysaccharide from nitraria tangutorum seeds

A technology for extracting oil from Nitraria seeds, applied in the field of continuous extraction of oil, flavonoids and polysaccharides from Nitraria seeds, achieving the effect of simple and feasible extraction process, ingenious process design, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

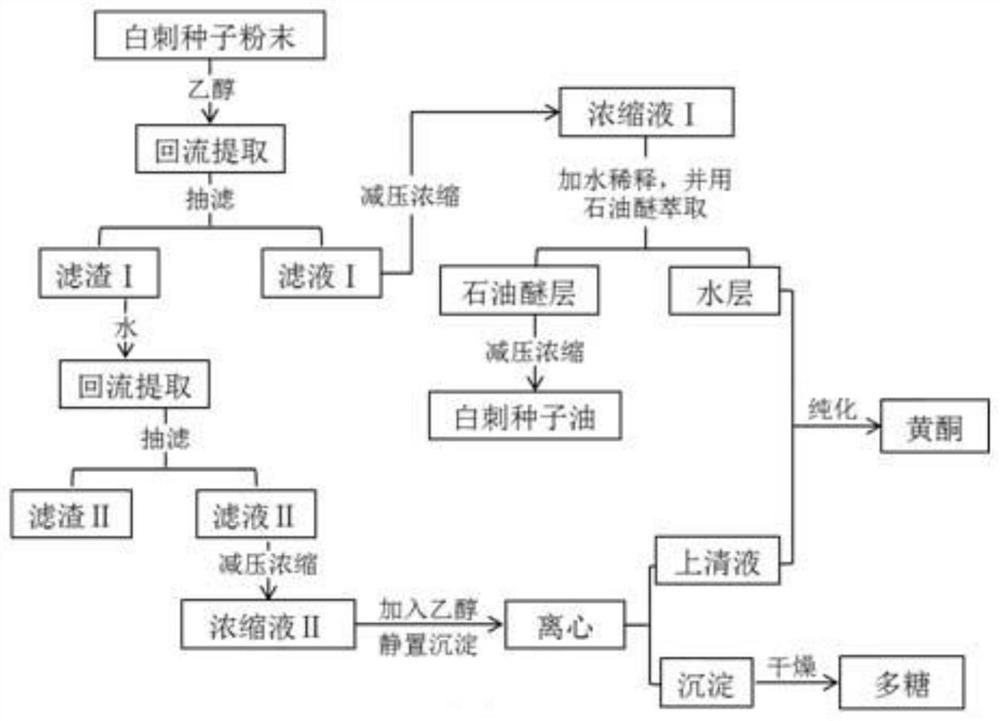

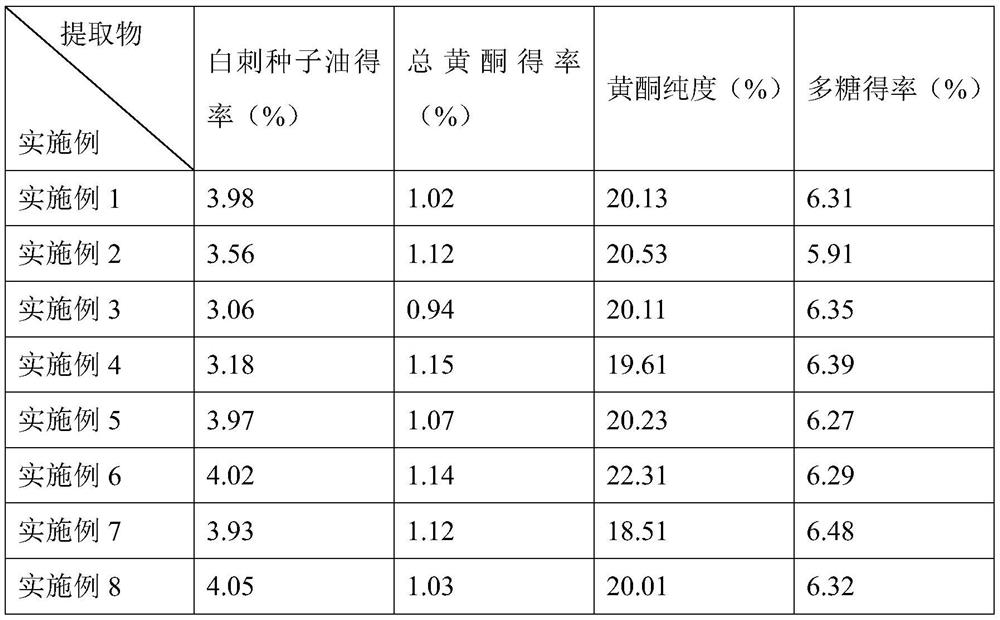

[0026] Such as figure 1 As shown, a method for continuously extracting oil, flavonoids and polysaccharides from Nitraria seeds, comprising the steps:

[0027] S1, separation of filter residue and filtrate: dry the cleaned Nitraria seeds until the moisture content is 4.30%, pass through a 40-mesh sieve after crushing to obtain Nitraria seed powder, then add 95% ethanol according to the liquid-to-material ratio of 10:1mL / g, Reflux extraction at 85°C for 2 times, each time for 2h, suction filtration and combined filtrates to obtain filtrate I and filter residue I.

[0028] S2. Oil extraction: Concentrate the filtrate I in step S1 under reduced pressure at 60°C to obtain the concentrated solution I, dilute it with pure water accounting for 1 / 2 of the volume of the concentrated solution I, and then add 3 times the volume of the diluted concentrated solution The petroleum ether was extracted twice, each time for 30 minutes, and the petroleum ether layer and the water layer were sep...

Embodiment 2

[0032] Such as figure 1 As shown, a method for continuously extracting oil, flavonoids and polysaccharides from Nitraria seeds, comprising the steps:

[0033]S1, separation of filter residue and filtrate: dry the cleaned Nitraria seeds until the moisture content is 4.30%, pass through a 40-mesh sieve after crushing to obtain Nitraria seed powder, then add 95% ethanol according to the liquid-to-material ratio of 10:1mL / g, Reflux extraction at 75°C for 2 times, each time for 2 hours, and suction filtration and combined filtrates to obtain filtrate I and filter residue I.

[0034] S2. Oil extraction: Concentrate the filtrate I in step S1 under reduced pressure at 60°C to obtain the concentrated solution I, dilute it with pure water accounting for 1 / 2 of the volume of the concentrated solution I, and then add 3 times the volume of the diluted concentrated solution The petroleum ether was extracted twice, each time for 30 minutes, and the petroleum ether layer and the water layer ...

Embodiment 3

[0038] Such as figure 1 As shown, a method for continuously extracting oil, flavonoids and polysaccharides from Nitraria seeds, comprising the steps:

[0039] S1, separation of filter residue and filtrate: dry the cleaned Nitraria seeds until the moisture content is 4.25%, pass through a 40-mesh sieve after crushing to obtain Nitraria seed powder, then add 95% ethanol according to the liquid-to-material ratio of 10:1mL / g, Reflux extraction at 85°C for 2 times, each extraction for 1h, and suction filtration and combined filtrates to obtain filtrate I and filter residue I.

[0040] S2. Oil extraction: Concentrate the filtrate I in step S1 under reduced pressure at 60°C to obtain the concentrated solution I, dilute it with pure water accounting for 1 / 2 of the volume of the concentrated solution I, and then add 3 times the volume of the diluted concentrated solution The petroleum ether was extracted twice, each time for 30 minutes, and the petroleum ether layer and the water laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com