A kind of silicon wafer double-sided grinding equipment and its production process

A technology for double-sided grinding and silicon wafers, which is applied in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., which can solve the problem of poor quality of silicon wafers, inability to remove grinding impurities in time, and low yield. and other problems to achieve the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

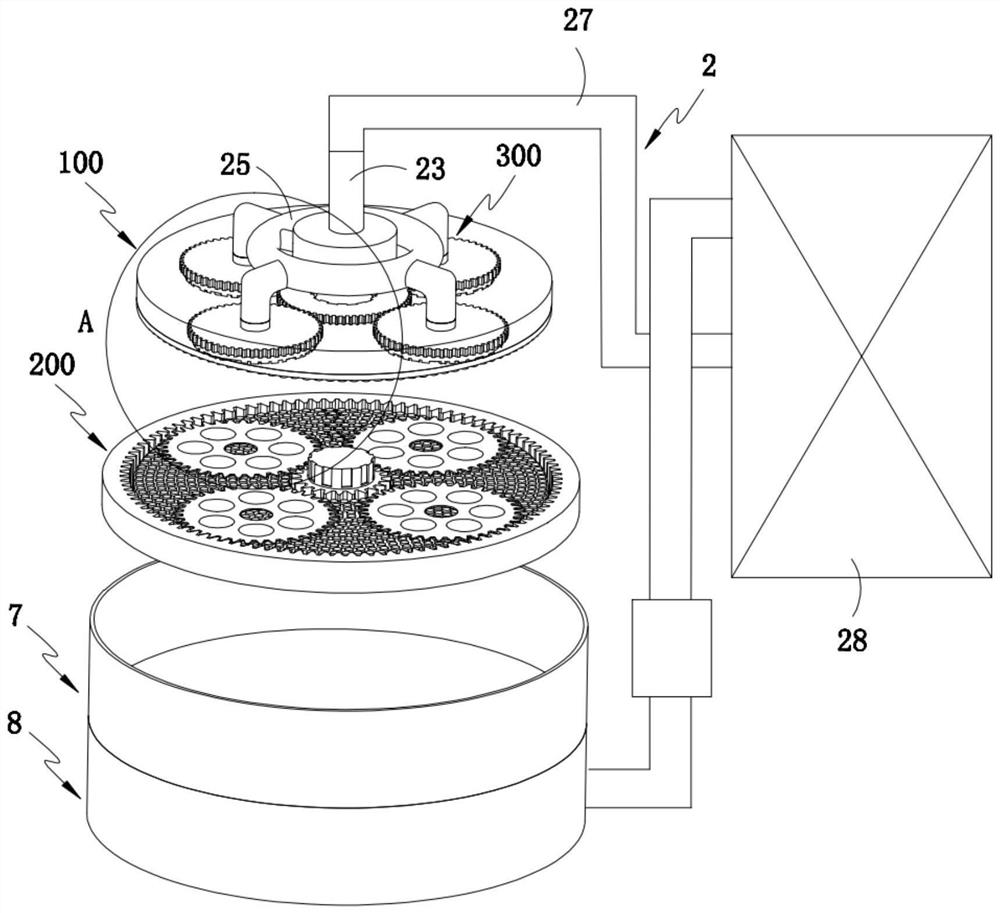

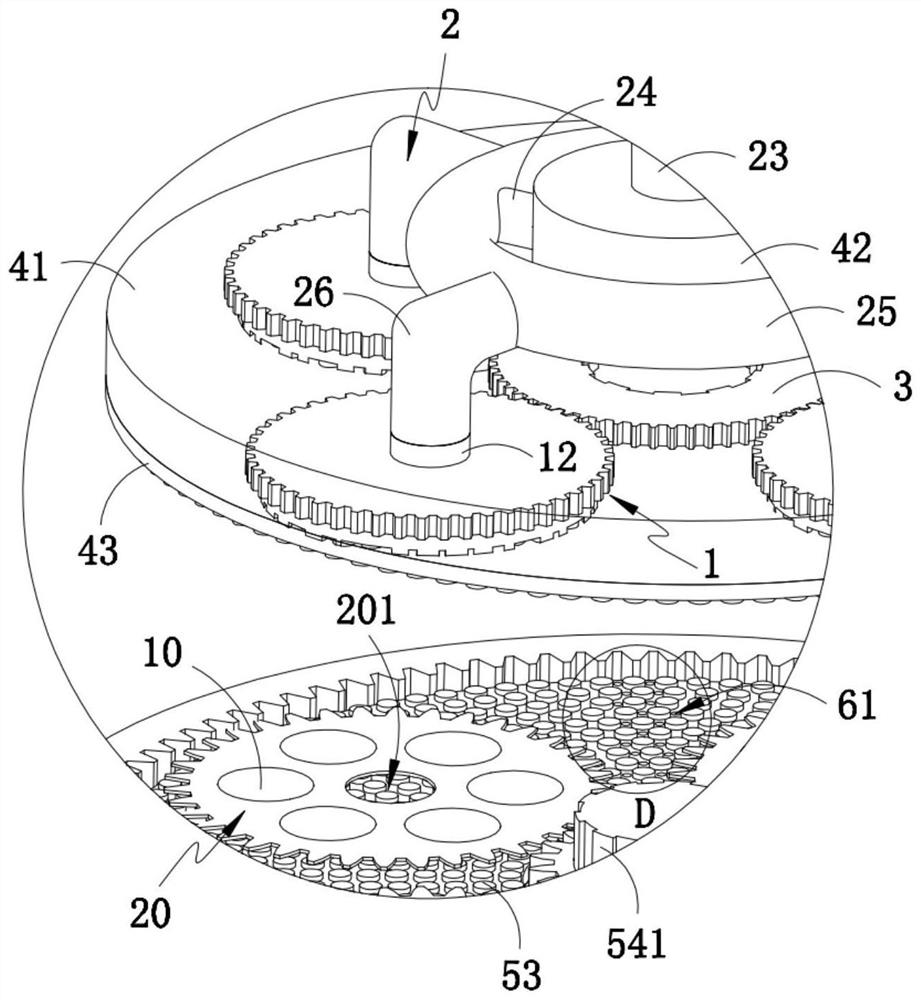

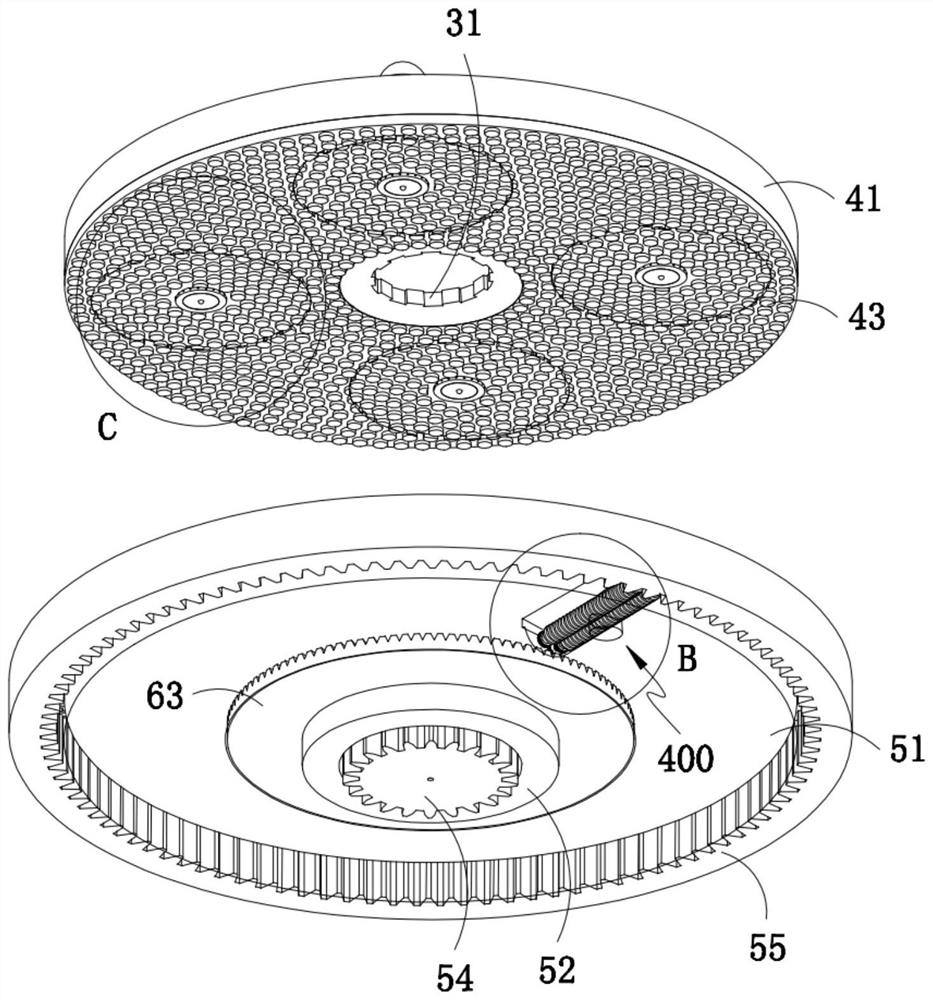

[0049] Such as Figure 1-2 As shown, a double-sided grinding device for silicon wafers includes an upper grinding disc system 100, a lower grinding disc system 200 that rotates in the opposite direction relative to the upper grinding disc system 100, and several loading silicon wafers 10 to be ground and placed on the grinding disc system 100. The lower planetary disc 20 that performs planetary motion between the upper grinding disc system 100 and the lower grinding disc system 200 also includes a spraying and sweeping debris removal system 300 arranged on the upper grinding disc system 100, and the spraying and sweeping debris removal system 300 includes Several upper planetary disc mechanisms 1 corresponding to the lower planetary disc 20, a liquid supply device 2 communicated with the upper planetary disc mechanism 1, and an upper transmission assembly 3 that drives the upper planetary disc mechanism 1 to rotate;

[0050] When the upper planetary disc mechanism 1 rotates ab...

Embodiment 2

[0084] For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 is described below; the difference between Embodiment 2 and Embodiment 1 is:

[0085] Further, such as Figure 8 As shown, the inner diameter r of the lower end of the outlet pipe body 121 at the nozzle 122 is smaller than the inner diameter R of the upper end;

[0086] In this embodiment, the inner diameter r at the nozzle 122 at the lower end of the water outlet pipe body 121 is set to be smaller than the inner diameter R at the upper end, so that when the valve opening groove 201 descends to open the nozzle 122, the hydraulic pressure at the nozzle 122 increases suddenly, so that The cleaning liquid 21 can be sprayed under high pressure, and the flushing intensity is high. In addition, the nozzle 122 is arranged to be inclined downward, so that the cleaning liquid 21 is sprayed at a certain angle with the surface of the lower planetary disc 20, and the flushing effect is better.

Embodiment 3

[0088] For the sake of simplicity, only the difference between Embodiment 2 and Embodiment 1 is described below; the difference between Embodiment 3 and Embodiment 1 is:

[0089] A kind of double-sided grinding production process of silicon wafer, such as Figure 11 shown, including the following steps:

[0090] Step 1, rotary grinding: take 4 to 5 lower planetary discs 20 and install them on the lower grinding disc system 200, put the silicon wafers 10 to be processed into the inner holes of the lower planetary discs 20 in sequence, and lower the upper grinding disc system 100 and apply pressure to start the grinding process;

[0091] In this embodiment, the grinding unit pressure is set at 1-2 N / cm2, the flow rate of pure water is set at 200-300 ml / min, and the rotation speed of the lower grinding disc is set at 40-50 rpm.

[0092] Step 2: Spray and remove debris: when the upper planetary disc mechanism 1 rotates above the lower planetary disc 20 and its top bead 124 falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com