Refining method for reducing aldehyde content and odor of polyether polyol

A technology of polyether polyol and refining method, which is applied in the direction of separation by moving adsorbent, can solve the problems of high odor and high aldehyde content of polyether polyol, and achieve the goal of reducing aldehyde content, increasing yield and reducing residual amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

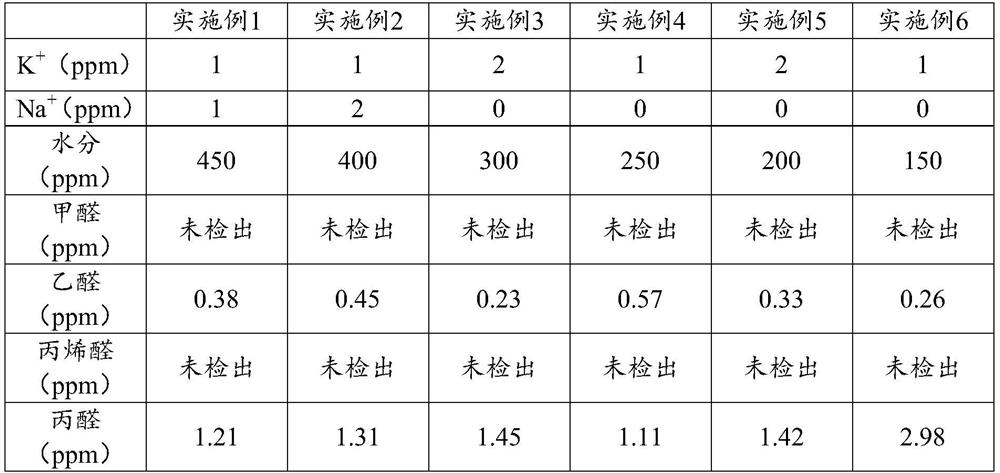

Embodiment 1

[0042]Add 1000g of crude polyether polyol 1 into a 2L stainless steel reaction kettle. At this time, when the temperature is 30°C, add 20g of deionized water, and raise the temperature to about 80°C while stirring. After stirring for 30min, add synthetic magnesium silicate adsorbent 2g, 0.5g of activated carbon, keep the temperature at about 80°C, stir for 60min, and press filter for 20min to measure the content of potassium ion and sodium ion in the polyether polyol product after press filtration, respectively 2ppm and 1ppm, add antioxidant 1010 About 0.3g, after stirring for 10 minutes, turn on the vacuum device and raise the temperature for dehydration, keep the temperature at 115°C, dehydrate until the moisture content is ≤0.05wt%, the dehydration is completed and the refined polyether polyol product 1 is obtained, the index and VOC content of the product are tested, and the results are shown in in FIG. 1.

Embodiment 2

[0044] Add 1000g of crude polyether polyol 2 into a 2L stainless steel reaction kettle. When the temperature is 50°C, add 30g of deionized water and raise the temperature to about 90°C while stirring. After stirring for 60min, add 5g of synthetic magnesium silicate adsorbent. Activated carbon adsorbent 2g, keep the temperature at about 85°C, stir for another 70min, and press filter for 20min to measure the content of potassium ion and sodium ion in the product after press filtration, respectively 1ppm and 1ppm, add about 0.5g of antioxidant 1010, stir After 10 minutes, turn on the vacuum device and raise the temperature for dehydration. Keep the temperature at 120°C. When the dehydration reaches a moisture content of ≤0.05wt%, the dehydration is completed to obtain the finished product 2 of polyether polyol. The index and VOC content of the product are tested, and the results are shown in Table 1.

Embodiment 3

[0046] Add 1000g of crude polyether polyol 3 into a 2L stainless steel reaction kettle. When the temperature is 80°C, add 50g of deionized water, and raise the temperature to about 95°C while stirring. After stirring for 60min, add 5g of synthetic magnesium silicate adsorbent. Activated carbon adsorbent 2.5g, keep the temperature at about 95°C, stir for another 60min, and press filter for 20min after circulating to measure the content of potassium ion and sodium ion of the product after press filtration are 2ppm and 0ppm respectively, add about 1.5g of antioxidant 1010, After stirring for 10 minutes, turn on the vacuum device and raise the temperature for dehydration. Keep the temperature at 115 ° C. When the dehydration reaches a moisture content of ≤0.35 wt%, the dehydration is completed to obtain the refined polyether polyol product 3. The indicators and VOC content of the product are tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com