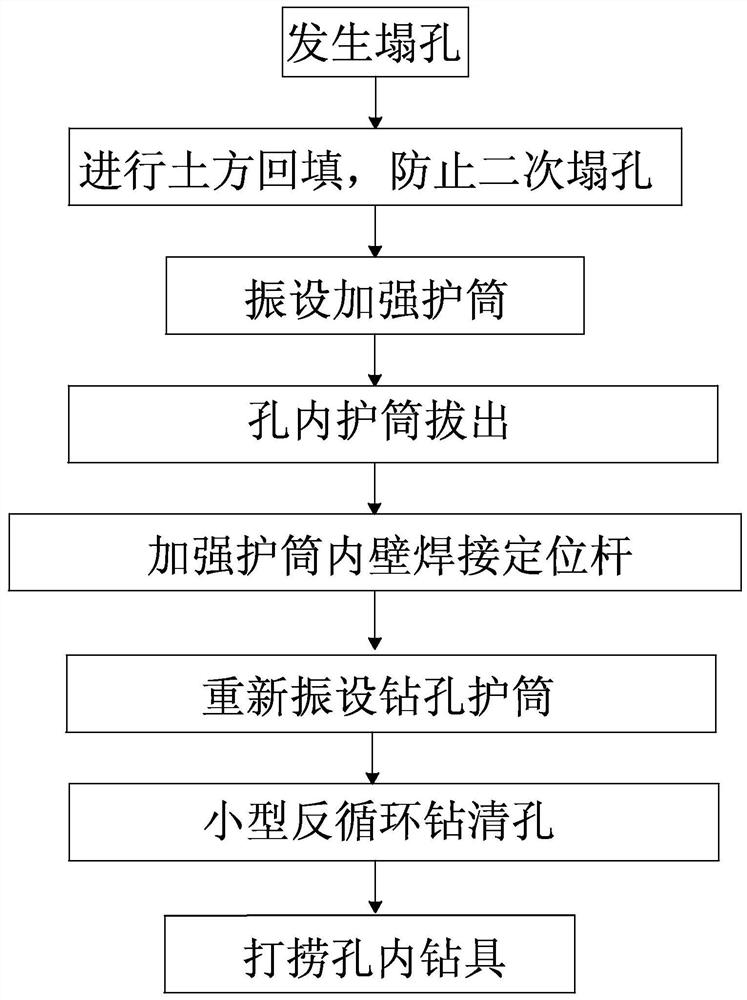

A method for buried drilling treatment of collapsed hole of pile foundation in aeolian sand stratum

A treatment method and technology of aeolian sand, applied in drilling equipment and methods, excavation, earthwork drilling and other directions, can solve the problems of difficulty in cleaning fine sand in the pile hole, deflection of the casing, damage to the drill pipe, etc. Hole cleaning progress, guarantee construction progress, and ensure the effect of punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The method of the present invention will be described below in conjunction with a specific embodiment.

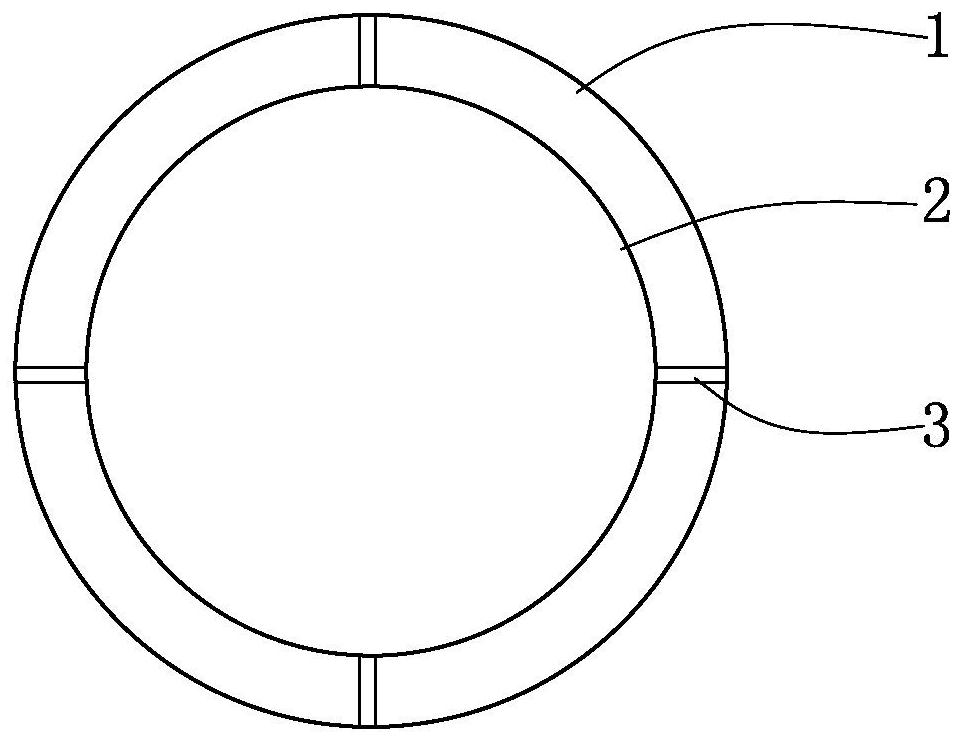

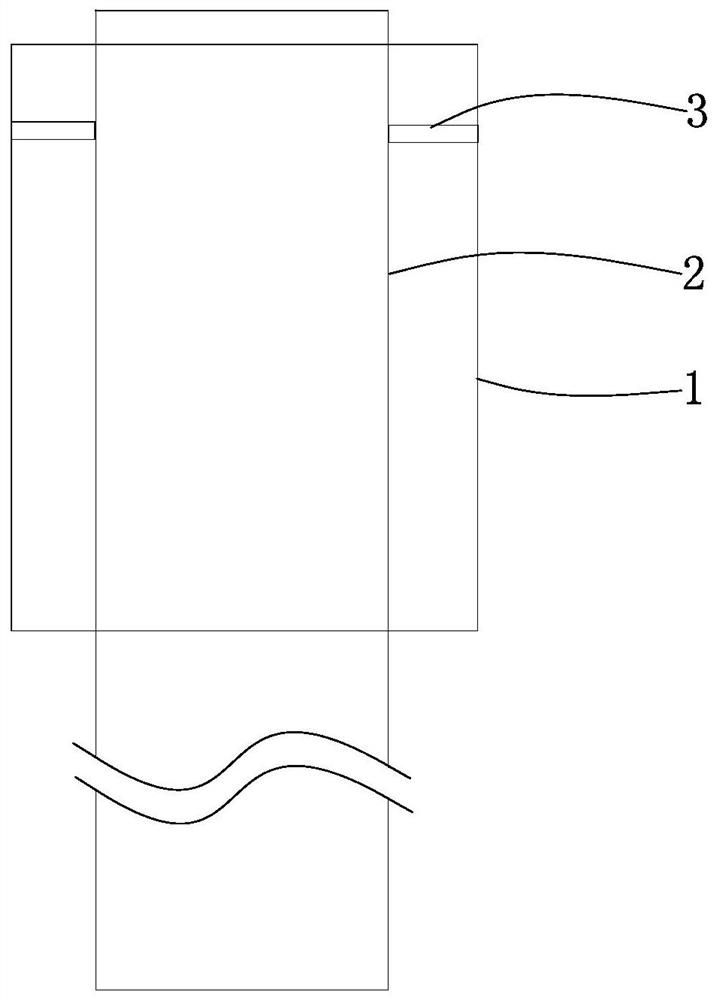

[0026] For a large bridge project, the maximum pile diameter of the pile foundation is 2.5m, the longest pile length is 99m, and the thickness of the aeolian sand covering layer at the pier exceeds 100m. The pile hole construction of this project adopts a φ2.8m steel casing, and a rotary drill is used for drilling construction. During the normal drilling process of the pile hole, it was found that the slurry was not normal, and the drill pipe was about to be lifted, but it was found that the drill pipe could not be lifted, and then it was found that the ground subsided and the casing sank. At this time, the drilling depth was 48m, and the hole depth after the collapse was only 22m, the casing sank by 2.5m, and one side deflection appeared, the maximum diameter of the collapsed hole reached 5.5m, and there were 15 sections of drill pipe (each section 3m) and 6.15m of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com